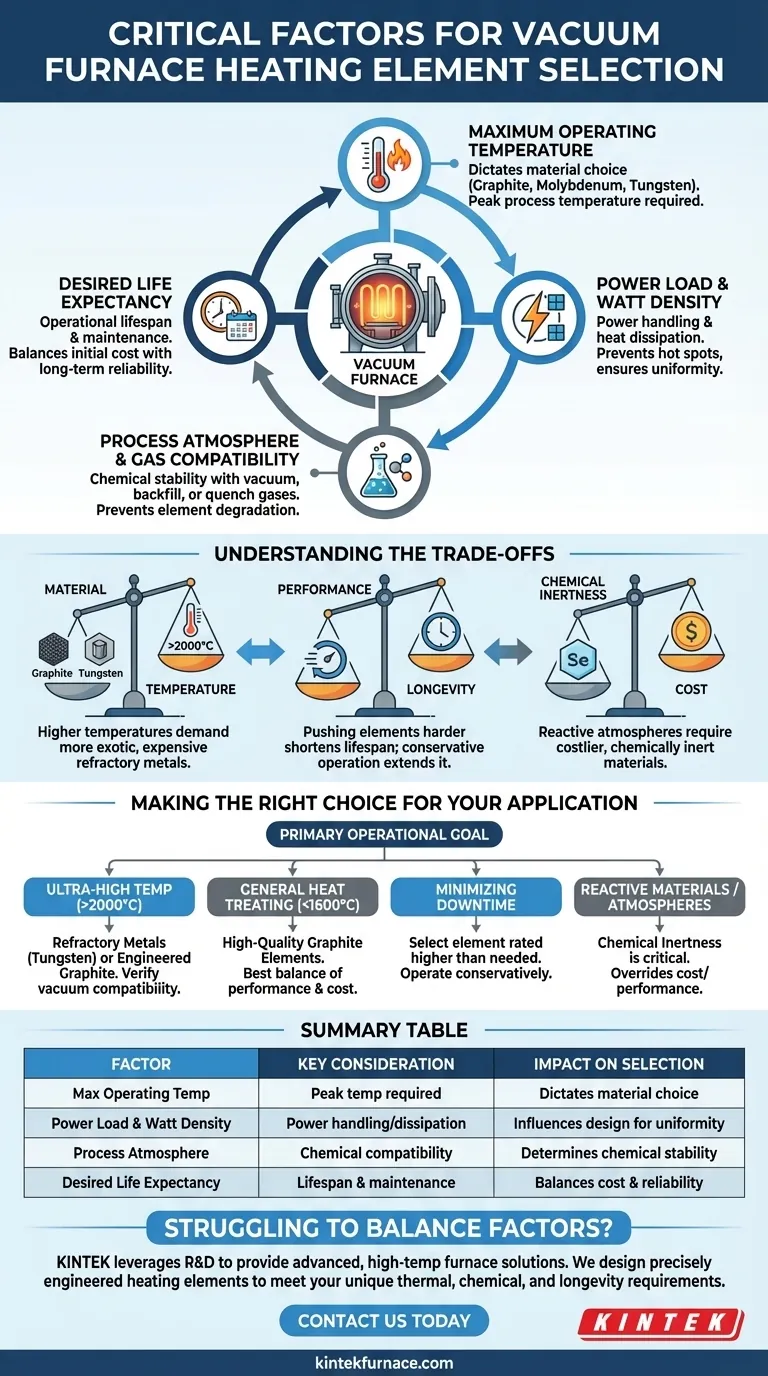

Selecting the right heating element for a vacuum furnace is a decision driven by a precise set of interconnected factors. The most critical considerations are the maximum operating temperature required, the electrical power load, the chemical compatibility with process and quench gases, and the desired operational life expectancy of the element itself.

Your heating element is not an isolated component; it is the heart of a system. Its selection is a critical balancing act between the physical demands of your process temperature, the chemical environment of your vacuum chamber, and the long-term economic realities of production and maintenance.

The Core Factors of Element Design

To choose the correct heating element, you must evaluate how your specific application impacts four critical areas. Each factor influences the others, making a holistic assessment essential.

Maximum Operating Temperature

The single most significant factor is the peak temperature your process requires. This directly dictates the material of the heating element.

Different materials have distinct temperature ceilings. For example, graphite is a common and cost-effective choice for many applications, while molybdenum and tungsten are required for higher and ultra-high temperature processes.

Power Load and Watt Density

This refers to the amount of electrical power the element can handle and dissipate as heat over its surface area. A higher watt density allows for faster heating rates and greater thermal uniformity.

The element's design—its shape, thickness, and surface area—must be engineered to handle the required power load without overheating or creating hot spots, which can lead to premature failure.

Process Atmosphere and Gas Compatibility

A vacuum is not truly empty. The residual gases, any gases backfilled for partial pressure processes, or gases used for rapid quenching can all interact with the heating element.

At high temperatures, chemical reactions can occur that degrade the element. For instance, certain materials can be compromised by oxygen, nitrogen, or carbon-bearing gases, leading to embrittlement or burnout. The element must remain chemically stable in your specific process environment.

Desired Life Expectancy

Life expectancy is fundamentally an economic consideration. An element that is less expensive but requires frequent replacement can lead to significant costs in terms of both parts and lost production time.

Operating an element consistently at its maximum rated temperature will drastically shorten its life. Designing the system with an element rated for a higher temperature than you need is a common strategy to extend its service life significantly.

Understanding the Trade-offs

Selecting an element is never about finding a single "best" option, but rather the optimal compromise for your specific needs. Failing to recognize these trade-offs is a common source of operational failure and unexpected cost.

Material vs. Temperature

The need for higher temperatures forces the use of more exotic and expensive refractory metals. While graphite is excellent for many processes up to and beyond 2000°C, applications requiring even higher temperatures or specific chemical inertness will demand costlier materials like tungsten.

Performance vs. Longevity

You can often push a heating element harder to achieve faster cycle times, but this almost always comes at the cost of its operational lifespan. A more conservative power application and operating temperature will yield a much longer-lasting and more reliable system.

Chemical Inertness vs. Cost

An element might perfectly meet your temperature and power requirements but be chemically incompatible with your process. A reaction between the element and the material being processed (outgassing) can contaminate your product or destroy the element. This may force you to select a more expensive but chemically inert material.

Making the Right Choice for Your Application

Your final decision should be guided by your primary operational goal. Analyze your process to determine which factor is the non-negotiable priority.

- If your primary focus is ultra-high temperature processes (>2000°C): Prioritize refractory metals like tungsten or meticulously engineered graphite, and verify their compatibility with your specific vacuum levels.

- If your primary focus is general-purpose heat treating or brazing (<1600°C): High-quality graphite elements typically offer the best balance of performance, durability, and cost-effectiveness.

- If your primary focus is minimizing operational downtime: Select an element rated for a temperature significantly higher than your process needs and operate it conservatively to maximize its service life.

- If you are working with reactive materials or atmospheres: The chemical inertness of the heating element is your most critical factor, potentially overriding all other cost and performance considerations.

Ultimately, an effective heating element is one that is perfectly matched to the specific thermal, chemical, and economic demands of your vacuum furnace process.

Summary Table:

| Factor | Key Consideration | Impact on Selection |

|---|---|---|

| Maximum Operating Temperature | Peak process temperature required. | Dictates material choice (e.g., Graphite, Molybdenum, Tungsten). |

| Power Load & Watt Density | Power handling and heat dissipation capability. | Influences element design to prevent hot spots and ensure uniformity. |

| Process Atmosphere | Chemical compatibility with vacuum, backfill, or quench gases. | Determines chemical stability and prevents element degradation. |

| Desired Life Expectancy | Operational lifespan and maintenance costs. | Balances initial cost with long-term reliability and uptime. |

Struggling to balance temperature, atmosphere, and cost for your vacuum furnace heating element? You don't have to compromise. KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced, high-temperature furnace solutions. Our product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by deep customization capabilities. We design heating elements that are precisely engineered to meet your unique temperature, chemical, and longevity requirements, ensuring optimal performance and reliability. Contact us today to discuss your specific application and let our experts deliver a solution that maximizes your process efficiency and ROI. Get in touch with our engineering team now!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment