The primary advantage of using an industrial vacuum oven for biomass powders is the ability to lower the boiling point of moisture, enabling evaporation at significantly reduced temperatures. This protects the biomass from the thermal degradation and oxidation associated with conventional high-temperature air ovens, ensuring the material remains chemically stable for subsequent stages like pre-carbonization.

By manipulating pressure rather than just temperature, vacuum ovens decouple drying speed from thermal stress. This allows you to rapidly remove moisture while preserving the delicate chemical structure of biomass materials, a critical requirement for high-quality downstream processing.

Preserving Material Integrity Through Physics

The Low-Temperature Advantage

Conventional ovens rely on high heat to force evaporation, which can be destructive to organic materials. In contrast, a vacuum oven reduces the ambient pressure within the chamber.

This pressure drop lowers the boiling point of water and other solvents. Consequently, moisture evaporates rapidly at much cooler temperatures, protecting heat-sensitive biomass from thermal shock.

Preventing Thermal Degradation

Biomass powders are often susceptible to breaking down when exposed to the high heat required by standard atmospheric drying.

By operating at lower temperatures, vacuum drying prevents the breakdown of the raw material's structure. This ensures that the essential properties of the biomass are retained for the next phase of production.

Enhancing Chemical Stability

Eliminating Oxidation Risks

In a conventional oven, heating powder in the presence of air often leads to unwanted oxidation. This is particularly problematic for biomass intended for carbonization or chemical processing.

Vacuum ovens operate in an oxygen-deprived environment. This mechanism effectively inhibits oxidation and side reactions, ensuring the chemical purity of the powder surface is maintained.

Preparing for Pre-Carbonization

For biomass powders destined for carbonization, surface chemistry is vital. The primary goal of preliminary drying is not just moisture removal, but stabilization.

Using a vacuum oven ensures the material remains chemically stable. This creates a predictable, high-quality baseline for the pre-carbonization stage, leading to better final product consistency.

Process Efficiency and Microstructure

Accelerated Drying Cycles

Despite using lower temperatures, the drying process in a vacuum oven is often faster than conventional methods.

The vacuum environment creates a larger driving force for evaporation. This shortens the overall drying cycle, improving throughput without compromising the material's integrity.

Deep Moisture Removal

Biomass powders can form agglomerates that trap moisture deep within their structure. Standard air drying often forms a "crust" that traps this liquid inside.

The pressure differential in a vacuum oven helps draw moisture and air bubbles out from deep within powder clusters. This ensures a thorough dry and helps maintain porosity, preventing the formation of hard, unusable agglomerates.

Understanding the Trade-offs

While vacuum drying offers superior quality for biomass, it is essential to recognize the operational differences compared to conventional ovens.

Throughput Limitations

Vacuum ovens are typically batch-process units. They generally cannot match the continuous, high-volume throughput of large conveyor-belt air ovens used for less sensitive materials.

Complexity and Cost

These systems require vacuum pumps, seals, and pressure-rated chambers. This results in a higher initial capital investment and slightly more complex maintenance requirements than simple convective heat ovens.

Making the Right Choice for Your Goal

To determine if an industrial vacuum oven is the correct solution for your specific biomass application, consider your end-goals:

- If your primary focus is material quality and purity: Choose a vacuum oven to strictly prevent oxidation and thermal degradation, ensuring the biomass remains chemically stable.

- If your primary focus is process speed for heat-sensitive materials: Utilize the vacuum's ability to lower boiling points, allowing for rapid moisture removal without the risk of scorching or structural damage.

Ultimately, if your biomass powder requires strict chemical stability before carbonization, the vacuum oven is not just an alternative—it is a technical necessity.

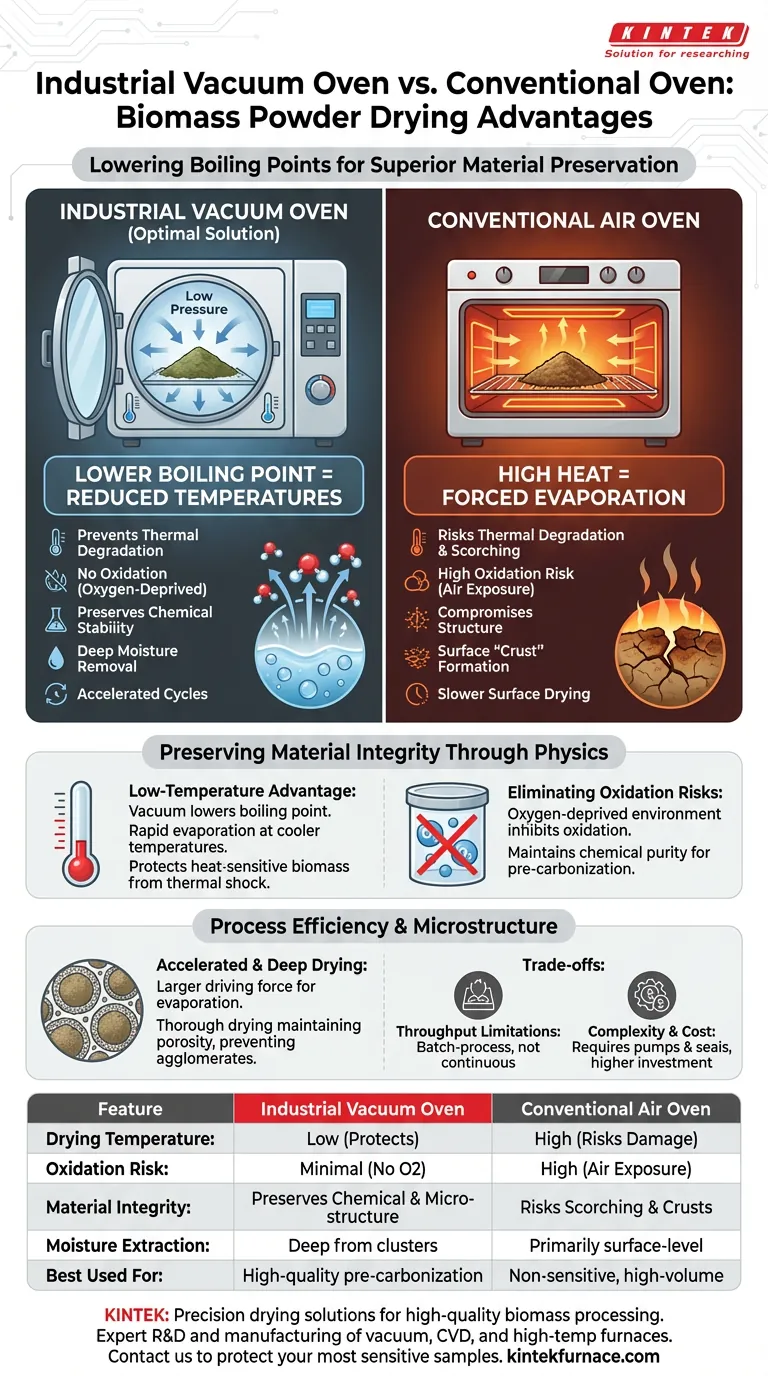

Summary Table:

| Feature | Industrial Vacuum Oven | Conventional Air Oven |

|---|---|---|

| Drying Temperature | Low (protects heat-sensitive biomass) | High (risks thermal degradation) |

| Oxidation Risk | Minimal (oxygen-deprived environment) | High (exposure to air at heat) |

| Material Integrity | Preserves chemical & micro-structure | Risks scorching and 'crust' formation |

| Moisture Extraction | Deep extraction from powder clusters | Primarily surface-level drying |

| Best Used For | High-quality pre-carbonization feedstock | Non-sensitive, high-volume materials |

Precision drying is the foundation of high-quality biomass processing. Backed by expert R&D and manufacturing, KINTEK offers specialized vacuum, CVD, and high-temp furnace systems designed to maintain the chemical purity of your materials. Whether you are prepping powders for carbonization or need a customizable solution for unique lab requirements, our team is ready to help. Contact KINTEK today to discover how our advanced vacuum technology can enhance your product consistency and protect your most sensitive samples.

Visual Guide

References

- Rohit Yadav, Kusum Kumari. Synthesis and Electrochemical Characterization of Activated Porous Carbon Derived from Walnut Shells as an Electrode Material for Symmetric Supercapacitor Application. DOI: 10.3390/engproc2023059175

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How are vacuum furnaces constructed and operated? Unlock Precision and Purity in Material Processing

- How do vacuum furnaces ensure precise heat treatment results? Master Control for Superior Material Properties

- What are vacuum furnaces used for? Achieve Unmatched Material Purity and Performance

- Why must a vacuum system maintain 3.6 mbar for plasma nitriding? Master Precision Surface Hardening

- How does temperature control precision of industrial melting furnaces affect intermetallic phase selection?

- Why is a vacuum drying oven used for TiB2 ceramic slurry? Protect Material Purity & Performance

- Why is a two-stage vacuum unit used in waste magnesium distillation? Optimize Pumping Speed and Process Stability

- What are the advantages of sintering furnaces? Achieve High-Quality, Dense Parts Efficiently