Precise vacuum control is the fundamental enabler of the plasma nitriding process. A specific low pressure, such as 3.6 mbar, is required to maintain a stable plasma glow discharge. This specific environment allows gas ions to gain the necessary speed and energy to bombard the workpiece effectively, which is impossible at higher pressures.

The specific vacuum level extends the "mean free path" of gas molecules, allowing ions to accelerate to high kinetic energies. This energy is critical for ensuring nitrogen atoms penetrate the material surface uniformly and efficiently.

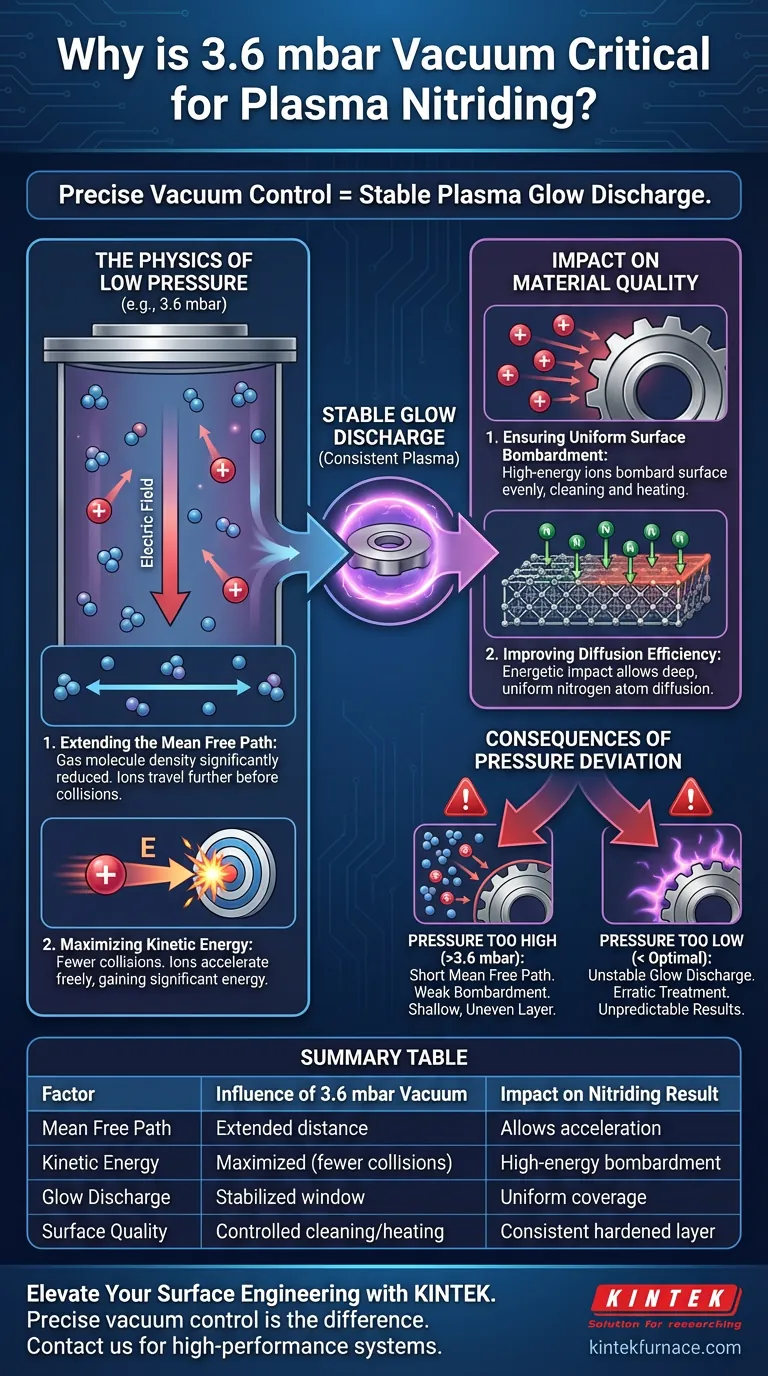

The Physics of Low Pressure

Extending the Mean Free Path

To understand why 3.6 mbar is critical, you must understand the behavior of gas molecules. At this specific low pressure, the density of gas molecules in the chamber is significantly reduced.

This reduction increases the "mean free path"—the average distance a molecule travels before colliding with another. By clearing the path, ions encounter fewer obstacles as they move through the vacuum chamber.

Maximizing Kinetic Energy

Because the ions collide with fewer gas molecules, they are not slowed down by resistance. Under the influence of the electric field, these positive ions can accelerate freely.

This allows them to gain significant kinetic energy. If the pressure were higher, frequent collisions would dissipate this energy, rendering the ions too weak to effectively interact with the workpiece.

Impact on Material Quality

Facilitating Stable Glow Discharge

A specific pressure window is required to ignite and sustain a stable glow discharge. This discharge is the visible manifestation of the plasma state.

Maintaining 3.6 mbar ensures the plasma remains consistent and covers the workpiece evenly. Without this stability, the treatment becomes erratic, leading to unpredictable results.

Ensuring Uniform Surface Bombardment

The high-energy ions created by this low-pressure environment bombard the surface of the workpiece with significant force. This bombardment is the mechanism that cleans the surface and heats it locally.

More importantly, this energetic impact is what allows nitrogen atoms to diffuse into the material's lattice. The uniformity of this bombardment directly correlates to the uniformity of the final hardened layer.

Improving Diffusion Efficiency

The ultimate goal of plasma nitriding is to diffuse nitrogen into the metal to harden it. The conditions created by the 3.6 mbar vacuum significantly improve this diffusion efficiency.

By ensuring ions hit the surface with the right energy, the process maximizes the depth and quality of the nitrided layer.

Understanding the Constraints

The Consequence of Pressure Deviation

The requirement for a "specific" pressure indicates that this is a precise operating window, not a general suggestion.

If the pressure rises significantly above 3.6 mbar, the mean free path shortens. Ions lose energy to collisions, resulting in weak bombardment and a shallow, uneven nitriding layer. Conversely, deviating too far below the optimal range can destabilize the glow discharge entirely.

Making the Right Choice for Your Goal

If your primary focus is Layer Uniformity: Maintain strict adherence to the 3.6 mbar setpoint to ensure the plasma glow surrounds complex geometries evenly.

If your primary focus is Process Efficiency: Monitor vacuum stability to maximize the kinetic energy of ions, ensuring the fastest possible nitrogen diffusion rates.

Control the pressure, and you control the energy that transforms your material.

Summary Table:

| Factor | Influence of 3.6 mbar Vacuum | Impact on Nitriding Result |

|---|---|---|

| Mean Free Path | Significantly extended distance between molecules | Allows ions to accelerate without interference |

| Kinetic Energy | Maximized due to fewer particle collisions | High-energy bombardment for deep nitrogen diffusion |

| Glow Discharge | Stabilized within a precise pressure window | Ensures uniform plasma coverage over complex parts |

| Surface Quality | Controlled ion bombardment cleaning/heating | Creates a consistent, high-quality hardened layer |

Elevate Your Surface Engineering with KINTEK

Precise vacuum control is the difference between a failed run and a superior hardened product. Backed by expert R&D and manufacturing, KINTEK offers high-performance vacuum systems, including CVD, Muffle, and customizable high-temperature furnaces designed to meet the rigorous demands of plasma nitriding and heat treatment.

Whether you need to maintain a strict 3.6 mbar environment or require a custom solution for complex geometries, our systems provide the stability and reliability your lab needs. Contact KINTEK today to discuss your vacuum furnace requirements and see how our expertise can optimize your material diffusion efficiency.

Visual Guide

References

- Magdalena Mokrzycka, Maciej Pytel. The influence of plasma nitriding process conditions on the microstructure of coatings obtained on the substrate of selected tool steels. DOI: 10.7862/rm.2024.1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

People Also Ask

- What is the function of titanium scraps in vacuum systems for HTGN? Boost Nitriding Depth with Oxygen Getters

- What are the primary differences in sintering strategies for ceramic membranes? Optimize Your Thermal Processing

- What are the key features of vacuum furnaces? Achieve Absolute Control for High-Performance Materials

- What are the applications of furnace brazing in the energy and power generation sector? Achieve Superior Joint Integrity for Critical Components

- What role does a rapid vacuum chamber play in measuring the evaporation rates? Achieve Precision Timing at t=0

- What is the purpose of the internal circulation pure water cooling system in vacuum sintering furnaces? Ensure Reliable Heat Management for High-Temperature Sintering

- What critical process environments does a high-vacuum furnace provide for boron carbide? Achieve Superior Densification

- What is the significance of purification and degassing in high-temperature vacuum furnaces? Achieve Superior Material Purity and Performance