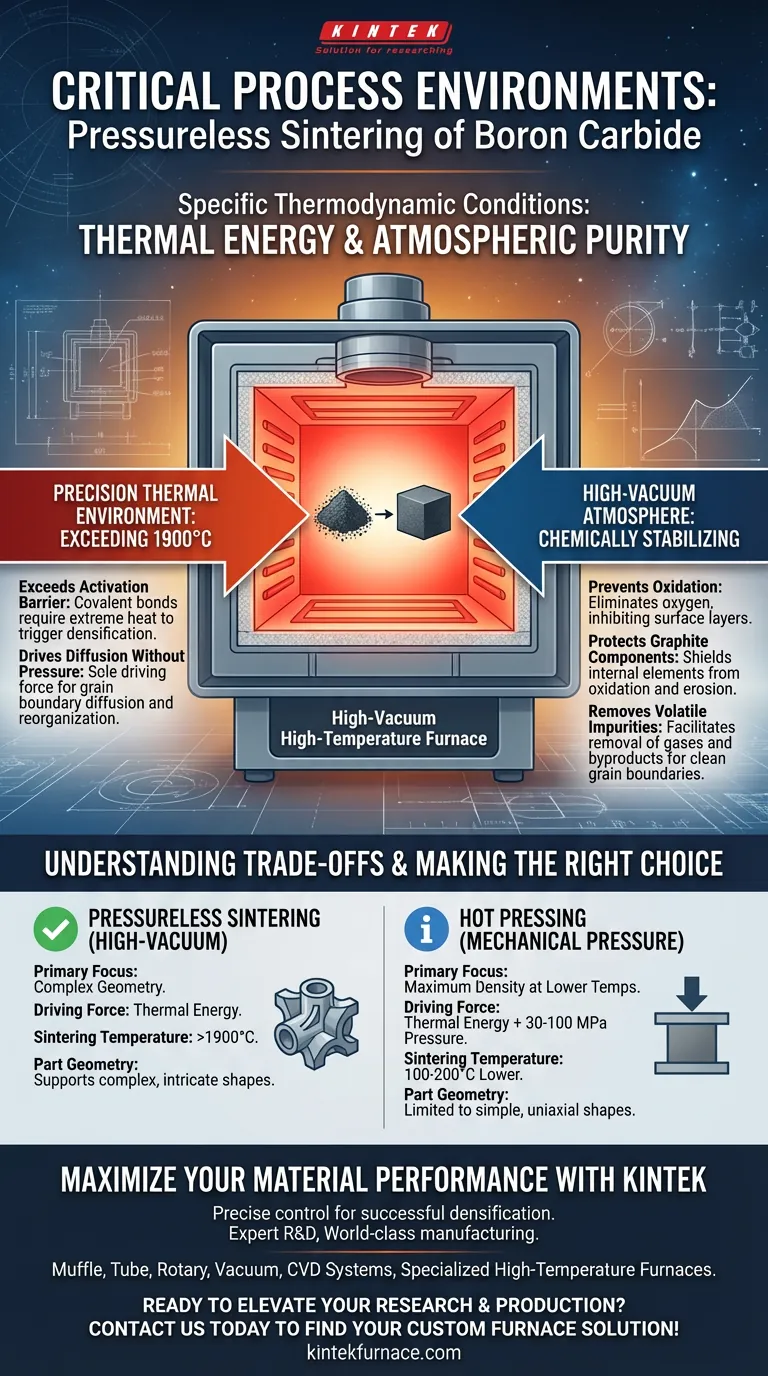

A high-vacuum high-temperature furnace creates the specific thermodynamic conditions necessary to sinter boron carbide without external mechanical force. Specifically, it generates a precise thermal environment exceeding 1900 degrees Celsius while simultaneously maintaining a high-vacuum atmosphere to chemically stabilize the material.

The core function of this equipment is to replace mechanical pressure with thermal energy and atmospheric purity. By eliminating oxygen and removing volatiles, the furnace allows grain boundary diffusion to drive densification entirely through heat, ensuring the integrity of both the boron carbide and the furnace's graphite components.

The Role of the Thermal Environment

Exceeding the Activation Barrier

Boron carbide is a covalent material with extremely strong chemical bonds, making it resistant to sintering.

To trigger densification, the furnace must provide precise temperature control exceeding 1900°C.

Driving Diffusion Without Pressure

In a pressureless process, there is no mechanical force (such as a ram) to physically close pores.

Consequently, the furnace uses this extreme thermal energy as the sole driving force to activate grain boundary diffusion and grain reorganization.

The Critical Function of High Vacuum

Prevention of Oxidation

The most immediate threat to boron carbide sintering is oxygen. At high temperatures, boron carbide oxidizes rapidly, creating surface layers that inhibit bonding.

The high-vacuum environment eliminates oxygen from the chamber, preventing the degradation of the boron carbide powder.

Protection of Graphite Components

These furnaces often utilize graphite heating elements or insulation to achieve temperatures above 1900°C.

The vacuum environment is equally critical for protecting these internal graphite components from oxidation and erosion.

Removal of Volatile Impurities

During the sintering process, materials often release gases or volatile byproducts.

The vacuum actively facilitates the removal of these volatile substances, cleaning the grain boundaries to enable liquid-phase or solid-phase densification.

Understanding the Trade-offs

Higher Temperature Requirements

It is important to recognize that relying solely on a vacuum furnace changes the energy requirements compared to other methods.

While pressureless sintering is effective, it typically requires higher temperatures than vacuum hot pressing, which uses external pressure (30-100 MPa) to lower the necessary densification temperature by 100-200°C.

Sensitivity to Surface Activity

Because there is no external pressure to force particles together, the process is highly sensitive to particle surface chemistry.

If the vacuum level is insufficient to maintain surface activity, densification will stall, whereas a pressurized system might overcome slight surface impurities through brute force.

Making the Right Choice for Your Goal

To select the correct processing path, you must weigh geometric complexity against densification ease.

- If your primary focus is complex geometry: Rely on the high-vacuum high-temperature furnace, as pressureless sintering allows for net-shape manufacturing of intricate parts that cannot be uniaxially pressed.

- If your primary focus is maximum density at lower temperatures: Consider hot pressing, where mechanical pressure acts as an additional driving force to eliminate internal pores and lower thermal requirements.

Success in pressureless sintering ultimately depends on the furnace's ability to maintain a pristine, oxygen-free vacuum while delivering the extreme thermal energy required to fuse covalent bonds.

Summary Table:

| Feature | Pressureless Sintering (High-Vacuum) | Hot Pressing (Mechanical Pressure) |

|---|---|---|

| Sintering Temperature | Exceeds 1900°C | 100-200°C lower than pressureless |

| Driving Force | Thermal energy & grain boundary diffusion | Thermal energy + 30-100 MPa pressure |

| Atmosphere | High Vacuum (eliminates oxygen) | Vacuum or Inert Gas |

| Part Geometry | Supports complex, intricate shapes | Limited to simple, uniaxial shapes |

| Graphite Protection | Essential vacuum shielding | Integrated pressure/vacuum systems |

Maximize Your Material Performance with KINTEK

Precise control over high-vacuum and high-temperature environments is the difference between successful densification and material failure. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized high-temperature furnaces. Whether you need to sinter complex boron carbide geometries or require customized high-pressure solutions, our laboratory equipment is built for reliability and precision.

Ready to elevate your research and production? Contact us today to find your custom furnace solution!

Visual Guide

References

- O. A. Reutova, В. А. Светличный. Self‐Dispersing of (CuO<sub>x</sub>)<sub>n</sub> Species on Dark TiO<sub>2</sub> Surface as a Key to High‐Performance HER Photocatalysts. DOI: 10.1002/cctc.202500594

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does a vacuum drying oven assist in maintaining the high specific surface area of (Y0.2La0.2Nd0.2Gd0.2Sm0.2)CoO3 nanofibers?

- Why is a short working distance essential for miniature vacuum furnaces? Expert Insights for Clear Nanoscale Imaging

- How are vacuum furnaces environmentally friendly? Achieve Clean, Efficient Heat Treatment

- What is the primary function of vacuum furnace annealing for ZnS nanopowders? Achieve High-Purity Ceramic Performance

- What types of materials are compatible with low vacuum versus high vacuum furnaces? Choose the Right Furnace for Your Materials

- What are the common heating methods used in vacuum furnaces? Choose the Best for Your Materials

- Why is a de-oiling pre-treatment step required in magnesium sublimation? To Ensure High-Purity Recovery

- Why is the vacuum-assisted impregnation process necessary for UHTCMCs? Achieve Superior Composite Density