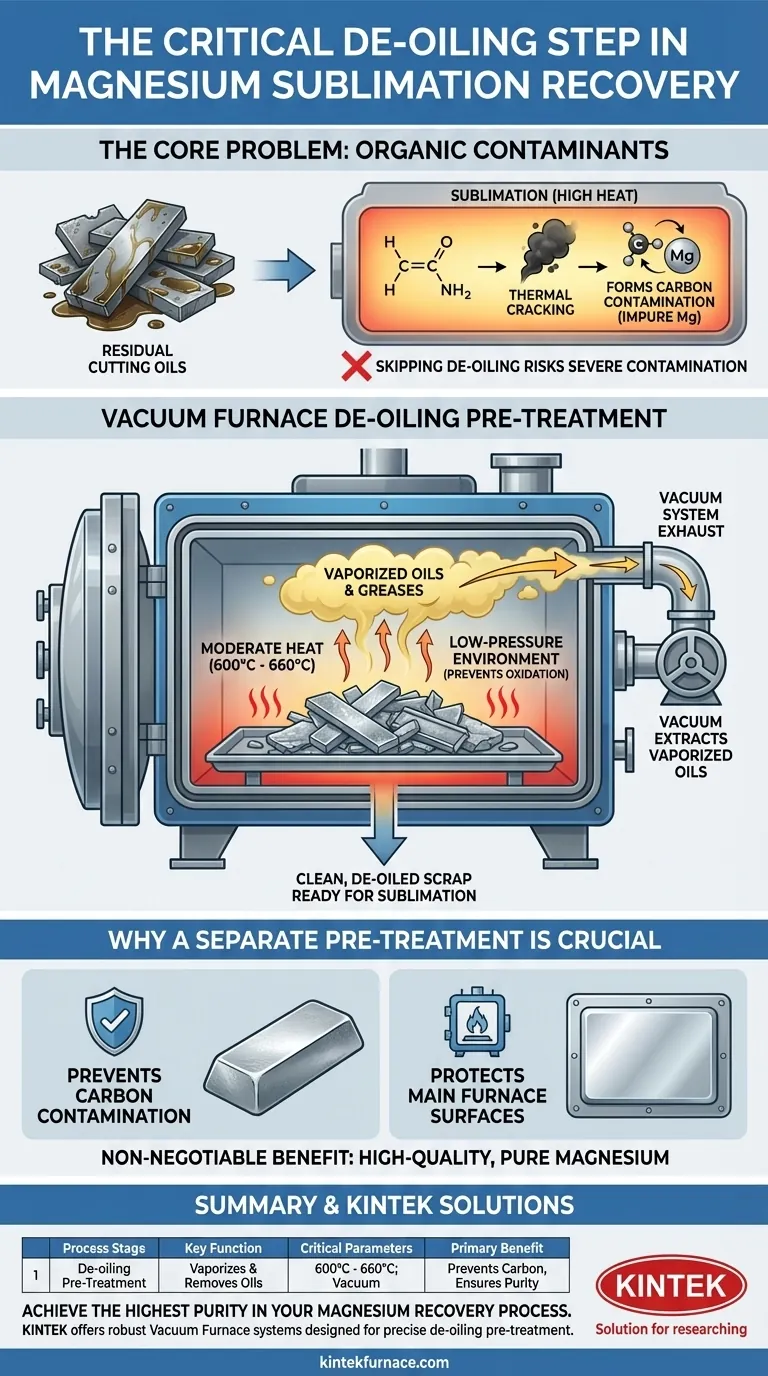

A de-oiling pre-treatment is a mandatory first step in the magnesium sublimation recovery process to eliminate organic contaminants like cutting oils from scrap material. If not removed, these oils break down under the high heat of sublimation, forming carbon that severely contaminates the final magnesium product. A vacuum furnace is used to gently heat the scrap, vaporizing these oils so a vacuum system can extract them completely before the primary purification stage begins.

The ultimate purity of recovered magnesium is determined not just by the final sublimation step, but by the critical pre-treatment that removes contaminants beforehand. De-oiling in a vacuum furnace is the essential first line of defense against carbon contamination.

The Core Problem: Organic Contaminants in Scrap

The Nature of the Contamination

Scrap magnesium, particularly from machining and fabrication processes, is almost always coated with residual cutting oils and other organic compounds.

These substances are physically present on the surface of the metal but are not part of the metallic alloy itself.

The Consequence of Inaction

During the high-temperature sublimation stage, these organic oils undergo a process called thermal cracking.

This chemical breakdown creates elemental carbon, which then mixes with and contaminates the purified magnesium, compromising its quality and performance characteristics.

How the Vacuum De-Oiling Process Works

The Role of Moderate Heat

The vacuum furnace heats the contaminated scrap to a carefully controlled temperature, typically between 600°C and 660°C.

This temperature is high enough to vaporize the oils and greases but remains below the point where magnesium would begin to melt or sublimate significantly. This ensures only the contaminants are targeted.

The Function of the Vacuum

The vacuum system serves two critical functions in this pre-treatment stage.

First, and most importantly, it acts as an exhaust, actively pulling the vaporized oil contaminants out of the furnace chamber.

Second, the low-pressure environment prevents the highly reactive magnesium from oxidizing as it's being heated, which would otherwise occur in the presence of air.

Why a Separate Pre-Treatment is Crucial

Performing de-oiling as a distinct step keeps the primary sublimation furnace clean.

If contaminated scrap were placed directly into the main furnace, the vaporized oils would contaminate the internal surfaces, especially the cold condensation plates, ruining not only the current batch but also subsequent recovery cycles.

Understanding the Trade-offs

The Added Process Complexity

Requiring a separate de-oiling step adds an extra stage to the overall workflow, increasing both the processing time and the capital investment in equipment.

This pre-treatment requires its own dedicated vacuum furnace, material handling, and process controls, separate from the main sublimation unit.

The Non-Negotiable Benefit: Purity

Despite the added complexity, this step is non-negotiable for producing high-quality magnesium.

Skipping it would result in a final product contaminated with carbon, rendering it unsuitable for most industrial applications and negating the economic benefit of the recovery process.

Making the Right Choice for Your Goal

- If your primary focus is maximizing purity: A dedicated vacuum de-oiling pre-treatment is an absolute requirement. There is no viable shortcut.

- If your primary focus is process efficiency: The key is to streamline the transfer between the de-oiling furnace and the sublimation furnace, not to eliminate the pre-treatment step itself.

- If your primary focus is on equipment design: The vacuum system must be robust enough to handle the extraction of significant oil vapor without compromising the integrity of the pumps or the main chamber.

Ultimately, effective pre-treatment is the foundation upon which a successful and profitable magnesium sublimation process is built.

Summary Table:

| Process Stage | Key Function | Critical Parameters |

|---|---|---|

| De-oiling Pre-Treatment | Vaporizes and removes cutting oils from scrap | Temperature: 600°C - 660°C; Operates under vacuum |

| Primary Benefit | Prevents carbon contamination of final magnesium product | Protects main sublimation furnace and ensures product purity |

Achieve the highest purity in your magnesium recovery process.

Skipping the de-oiling pre-treatment step risks severe carbon contamination, compromising your final product quality. The right equipment is critical for success.

Backed by expert R&D and manufacturing, KINTEK offers robust Vacuum Furnace systems designed for precise de-oiling pre-treatment and other high-temperature processes like sublimation. Our solutions are customizable to your unique scrap handling and purity requirements.

Ready to protect your investment and ensure high-purity magnesium recovery? Contact our experts today to discuss how our vacuum solutions can optimize your process.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control