At its core, a vacuum furnace's heating method is chosen based on the material, the part geometry, and the desired thermal outcome. The three most common heating methods are electrical resistance, electromagnetic induction, and radiation. Each mechanism transfers energy differently, making them suitable for distinct applications and temperature ranges.

Choosing a heating method isn't about which is "best," but which is the most appropriate tool for the job. Resistance heating offers broad versatility, induction provides unmatched speed for conductive materials, and radiation excels at delivering uniform high temperatures.

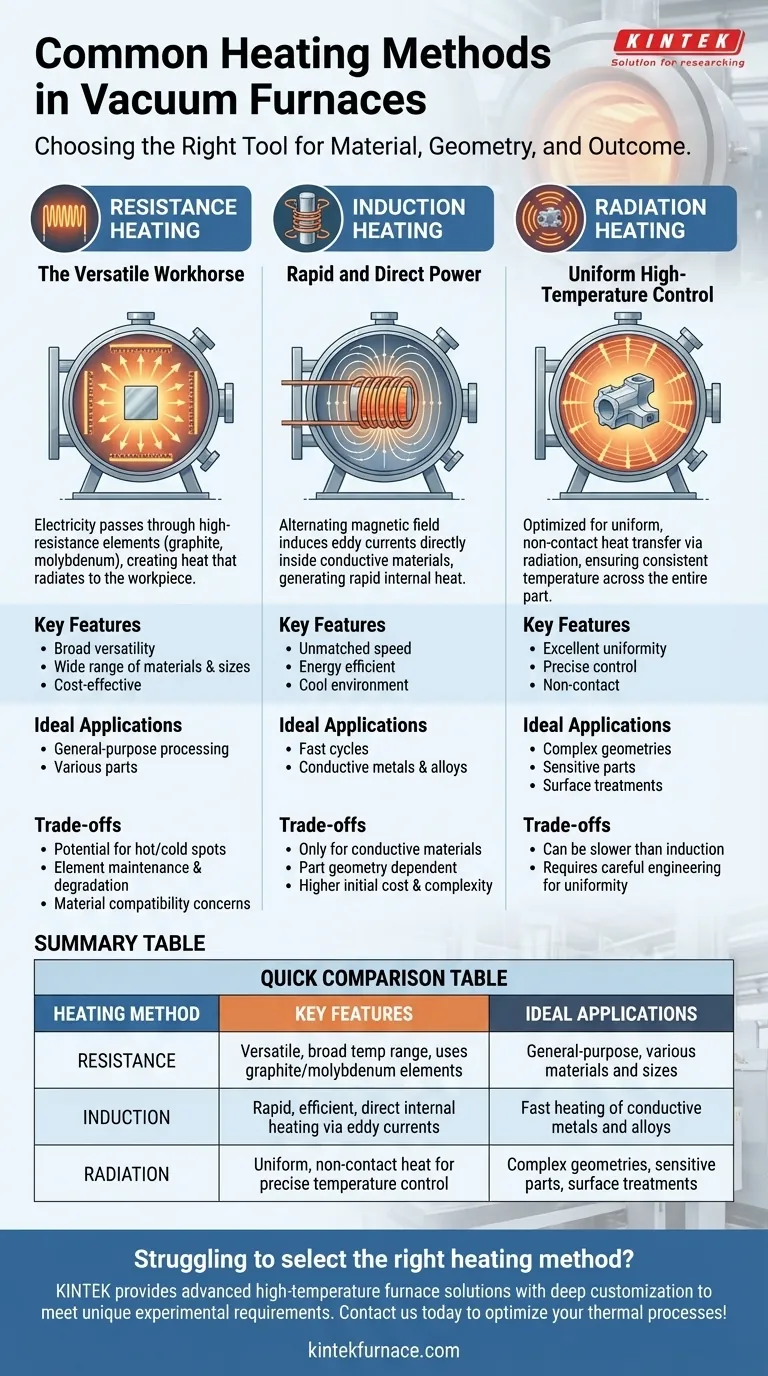

The Three Primary Heating Mechanisms

The way heat is generated and transferred within the vacuum is the fundamental difference between furnace types. This choice dictates the furnace's capabilities, limitations, and ideal applications.

Resistance Heating: The Versatile Workhorse

Resistance heating is the most prevalent method used in vacuum furnaces. It operates on a simple principle: electricity is passed through heating elements with high electrical resistance.

These elements, typically made of graphite or refractory metals like molybdenum, become incandescently hot and transfer their heat to the workpiece primarily through radiation. Think of it like the glowing coils in an electric toaster or stove, but operating at much higher temperatures in a controlled vacuum.

This method is highly versatile, capable of processing a wide variety of materials and part sizes.

Induction Heating: Rapid and Direct Power

Induction heating is a fundamentally different, non-contact process. It uses an alternating magnetic field, generated by a copper coil, to induce electrical eddy currents directly within the conductive workpiece.

These internal currents generate rapid and precise heat inside the material itself. The furnace walls and surrounding environment remain relatively cool, making it an extremely efficient method for energy transfer.

This technique is ideal for applications requiring fast heating cycles on conductive metals and alloys.

Radiation Heating: Uniform High-Temperature Control

While all heating in a vacuum ultimately involves radiation, the term "radiation heating" emphasizes the control of this transfer. In this context, it refers to systems designed specifically to provide extremely uniform, non-contact heat.

Heat radiates from the hot resistance elements and reflects off the furnace's internal surfaces to evenly envelop the workpiece. This is critical for parts with complex geometries or for processes like surface treatments where consistent temperature across the entire part is non-negotiable.

Understanding the Trade-offs

No single heating method is universally superior. The decision always involves balancing performance characteristics, material compatibility, and operational costs.

The Challenge of Temperature Uniformity

Resistance furnaces, while versatile, can create hot and cold spots if not engineered with multiple, well-placed heating zones. The workpiece's proximity to different elements can affect its final properties.

Induction heating is highly dependent on the part's geometry and its placement within the coil. Complex shapes may heat unevenly unless the induction coil is custom-designed for that specific part, which adds cost and complexity.

Material Compatibility and Limitations

The most significant limitation of induction heating is that it only works on electrically conductive materials. It cannot be used to heat ceramics or other non-conductive parts directly.

With resistance heating, the element material itself can be a factor. Graphite elements, for example, may not be suitable for processing certain materials that could react with carbon at high temperatures.

Cost, Complexity, and Maintenance

Resistance heating systems are generally the most cost-effective and mechanically simple option, making them a common choice for general-purpose applications.

Induction systems are more complex and carry a higher initial investment, particularly when custom coils are required. However, their speed and efficiency can lead to lower operating costs per part.

Finally, the heating elements in resistance furnaces are consumables that degrade over time and require periodic replacement, which is a key maintenance consideration.

Making the Right Choice for Your Goal

The heating method must be selected in the context of the entire thermal process, including the subsequent cooling or quenching cycle needed to achieve the final material properties.

- If your primary focus is versatility and processing a wide range of materials: Resistance heating is often the most practical and cost-effective solution.

- If your primary focus is rapid, high-efficiency heating of a specific conductive part: Induction heating offers unmatched speed and direct energy transfer.

- If your primary focus is achieving maximum temperature uniformity on complex or sensitive parts: A well-designed radiation heating system provides the most controlled environment.

Understanding these core principles empowers you to select a heating technology that serves your process, not the other way around.

Summary Table:

| Heating Method | Key Features | Ideal Applications |

|---|---|---|

| Resistance | Versatile, broad temperature range, uses graphite/molybdenum elements | General-purpose, various materials and sizes |

| Induction | Rapid, efficient, direct internal heating via eddy currents | Fast heating of conductive metals and alloys |

| Radiation | Uniform, non-contact heat for precise temperature control | Complex geometries, sensitive parts, surface treatments |

Struggling to select the right heating method for your vacuum furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tailored solutions can optimize your thermal processes and boost efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing