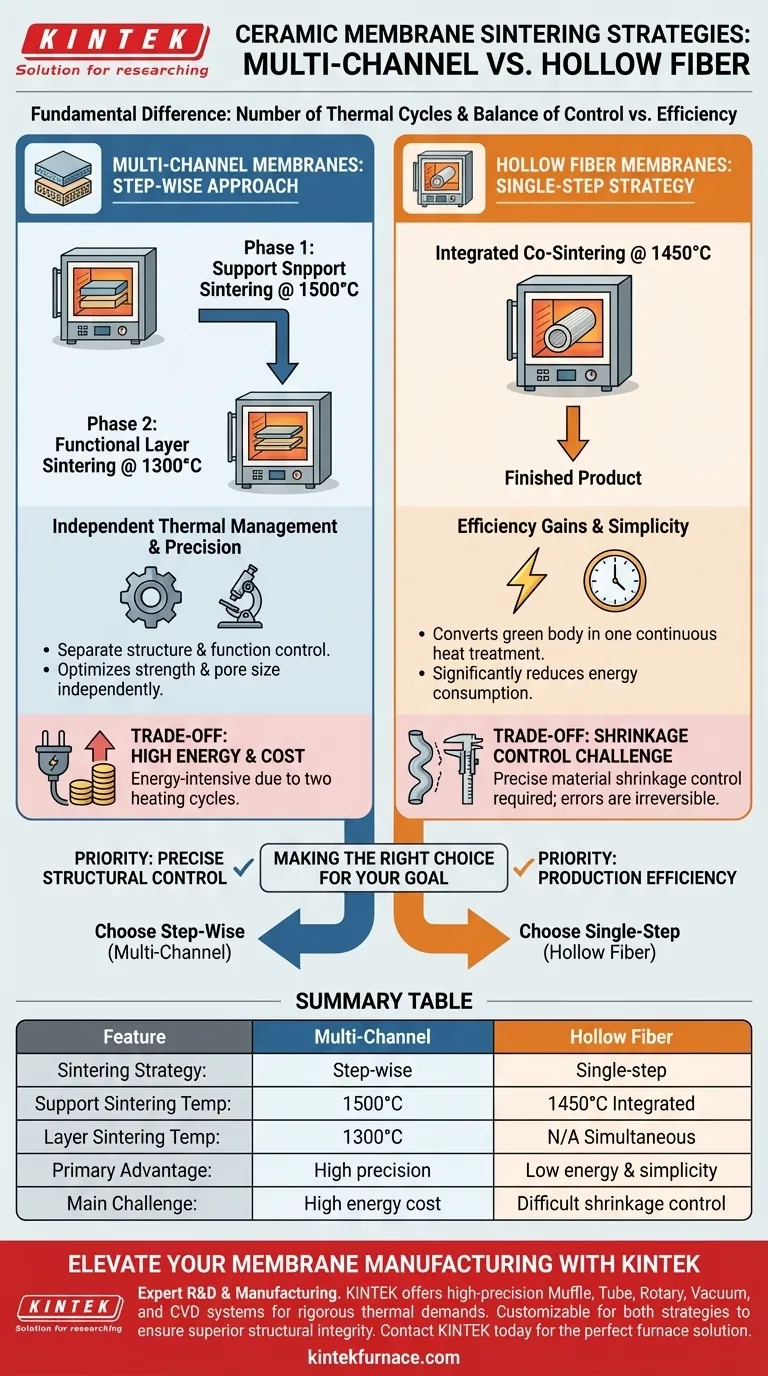

The fundamental difference lies in the number of thermal cycles required. Multi-channel ceramic membranes typically utilize a two-stage, step-wise sintering process, firing the support structure at 1500°C and the functional layer subsequently at 1300°C. In contrast, ceramic hollow fiber membranes employ a single-step co-sintering strategy at 1450°C to transform the green body into the final product in one continuous heat treatment.

The choice of sintering strategy dictates the balance between performance control and manufacturing efficiency: step-wise sintering offers independent structural management, while single-step sintering significantly reduces energy consumption.

Multi-Channel Membranes: The Step-Wise Approach

Separating Structure from Function

Multi-channel membranes generally require a step-wise sintering method. This involves two distinct heating phases rather than a single firing event.

Independent Thermal Management

The process begins by sintering the membrane support at a higher temperature of 1500°C. Following this, the functional layer is sintered at a lower temperature of 1300°C.

Precision in Property Control

By separating these steps, manufacturers can independently manage critical properties. This allows for the optimization of structural strength in the support layer and precise pore size control in the functional layer without one compromising the other.

Ceramic Hollow Fiber Membranes: The Single-Step Strategy

Integrated Co-Sintering

Ceramic hollow fiber membranes utilize a single-step sintering process. This approach converts the "green body" (the unfired ceramic) directly into the finished product in one go.

Operating Temperature

This single-step process typically occurs at 1450°C. It eliminates the need for cooling and reheating the materials for a second coating application.

Efficiency Gains

The primary advantage of this strategy is manufacturing simplicity. It significantly reduces the overall energy consumption required to produce the membrane.

Understanding the Trade-offs

The Cost of Precision

While the step-wise method used in multi-channel membranes ensures high structural integrity and pore precision, it is energy-intensive. Running furnaces up to 1500°C and then again to 1300°C increases production time and operational costs.

The Challenge of Shrinkage Control

The single-step approach for hollow fibers is more efficient but introduces technical risk. Because the entire structure is fired at once, precise control over material shrinkage is required.

Errors during this single heat treatment can distort the fiber's shape or compromise its integrity, leaving no room for the corrections that a multi-step process might allow.

Making the Right Choice for Your Goal

To determine which strategy aligns with your manufacturing or application requirements, consider the following principles:

- If your primary focus is precise structural control: Prioritize the step-wise method (multi-channel), as it allows you to optimize the support and functional layers independently.

- If your primary focus is production efficiency: Lean towards the single-step strategy (hollow fiber), which minimizes energy consumption and simplifies the manufacturing line.

Success ultimately depends on whether your priority is the granular management of membrane properties or the reduction of energy overhead in the production cycle.

Summary Table:

| Feature | Multi-Channel Ceramic Membranes | Ceramic Hollow Fiber Membranes |

|---|---|---|

| Sintering Strategy | Step-wise (Two-stage) | Single-step (Co-sintering) |

| Support Sintering Temp | 1500°C | 1450°C (Integrated) |

| Layer Sintering Temp | 1300°C | N/A (Simultaneous) |

| Primary Advantage | High pore size & structural precision | Low energy consumption & simplicity |

| Main Challenge | High energy & operational costs | Difficult shrinkage control |

Elevate Your Membrane Manufacturing with KINTEK

Precise sintering is the cornerstone of high-performance ceramic membranes. Backed by expert R&D and manufacturing, KINTEK offers high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous thermal demands of both step-wise and single-step sintering strategies.

Whether you require the granular temperature control needed for multi-channel support structures or the uniform high-temp stability for hollow fiber co-sintering, our lab high-temp furnaces are fully customizable to your unique research or production needs.

Ready to optimize your thermal management? Contact KINTEK today to find the perfect furnace solution and ensure your ceramic products achieve superior structural integrity.

Visual Guide

References

- Comparative Carbon Footprint Analysis of Alumina-Based Multichannel and Hollow Fiber Ceramic Membranes for Microfiltration. DOI: 10.3390/separations12080220

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does a vacuum sublimation furnace with rheological movement benefit high-moisture coal? Optimize Production Speed

- How does a laboratory vacuum high-temperature furnace maintain conditions for LiF-BeF2-LaF3? Expert Atmosphere Control

- What are the safety considerations when using nitrogen and argon in vacuum furnaces? Prevent Asphyxiation Risks in Your Lab

- Why is a vacuum environment important in a vacuum furnace? Ensure Purity and Precision in Material Processing

- How does the combined use of a centrifuge and a vacuum drying oven solve issues in H-Beta zeolite catalyst recovery?

- How do miniature vacuum furnaces ensure image stability? Advanced Engineering for High-Resolution Ceramic Imaging

- Why are vacuum furnaces considered important in various industries? Unlock Superior Material Performance

- Why is a precise and slow cooling rate necessary during Nb3Sn heat treatment? Ensure Peak Superconducting Performance