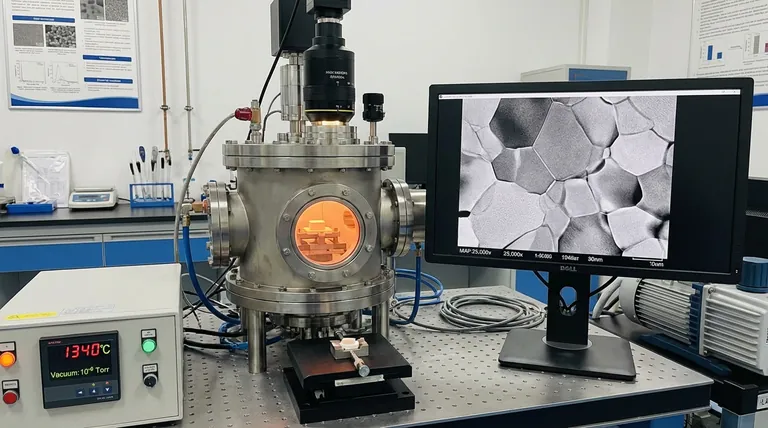

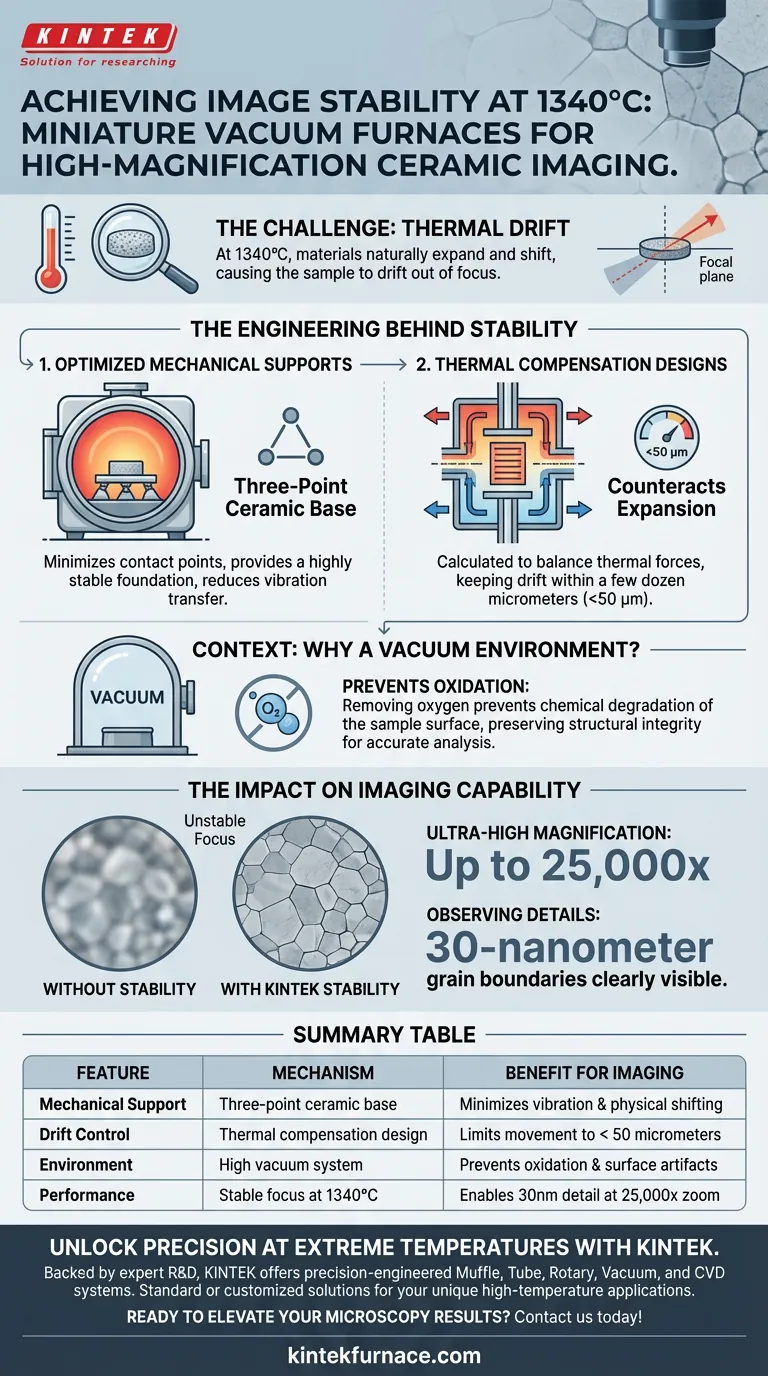

Miniature vacuum furnaces achieve image stability at extreme temperatures by employing optimized mechanical supports and advanced thermal compensation designs. Specifically, these systems utilize a three-point ceramic base to minimize physical shifting, effectively controlling thermal drift to within a few dozen micrometers even when heated to 1340°C. This precise engineering counteracts the natural expansion of materials, allowing for clear, high-magnification observation of microstructural details.

The core challenge of high-temperature microscopy is not just reaching the temperature, but maintaining focus while doing so. Specialized structural designs limit physical movement to mere micrometers, preserving the stability required to capture 30-nanometer details at 25,000x magnification.

The Engineering Behind Stability

Controlling Thermal Drift

At temperatures as high as 1340°C, materials naturally expand and shift. This phenomenon, known as thermal drift, is the primary obstacle to sharp imaging.

Without intervention, this movement would cause the sample to drift out of the microscope's focal plane immediately.

Optimized Mechanical Supports

To combat this, manufacturers utilize three-point ceramic bases.

This specific geometric configuration provides a highly stable foundation. It minimizes the contact points that can transfer vibration or stress, ensuring the sample remains physically secure during heating.

Thermal Compensation Designs

Beyond the physical base, the furnace incorporates thermal compensation designs.

These engineering features are calculated to counteract the expansion of specific components. By balancing the thermal forces, the system maintains a "neutral" position for the sample, keeping drift within a manageable range of a few dozen micrometers.

The Impact on Imaging Capability

Ultra-High Magnification

The stability provided by these supports allows for magnification levels up to 25,000x.

At this level of zoom, even microscopic vibrations would render an image useless. The mechanical rigidity of the furnace ensures the image remains crisp.

Observing Grain Boundaries

This stability is critical for materials science, particularly for ceramics like alumina.

Researchers can clearly observe 30-nanometer grain boundary details. This allows for the real-time analysis of sintering processes and microstructural evolution under heat.

Context: Why a Vacuum Environment?

Preventing Oxidation

While mechanical supports ensure stability, the vacuum environment plays a crucial supporting role. Heating metals or ceramics to 1340°C in air typically causes rapid, undesirable oxidation.

Preserving Surface Integrity

By removing oxygen, the vacuum furnace prevents chemical reactions that would degrade the sample surface.

This ensures that the structural details captured by the microscope are accurate representations of the material, not artifacts of surface corrosion.

Making the Right Choice for Your Research

If you are selecting equipment for high-temperature analysis, prioritize the underlying mechanical architecture.

- If your primary focus is nanometer-scale resolution: Verify that the system utilizes a three-point support system and has documented drift specifications under a few dozen micrometers.

- If your primary focus is sample purity: Ensure the vacuum system is capable of maintaining a strict oxygen-free environment to prevent surface oxidation at target temperatures.

True thermal microscopy requires a system where mechanical stability is engineered as strictly as the heating element itself.

Summary Table:

| Feature | Mechanism | Benefit for Imaging |

|---|---|---|

| Mechanical Support | Three-point ceramic base | Minimizes vibration & physical shifting |

| Drift Control | Thermal compensation design | Limits movement to < 50 micrometers |

| Environment | High vacuum system | Prevents oxidation & surface artifacts |

| Performance | Stable focus at 1340°C | Enables 30nm detail at 25,000x zoom |

Unlock Precision at Extreme Temperatures with KINTEK

Don't let thermal drift compromise your research. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all precision-engineered to provide the stability required for high-magnification analysis.

Whether you need a standard solution or a customized lab furnace for unique high-temperature applications, our systems deliver the thermal control and structural integrity your materials deserve.

Ready to elevate your microscopy results? Contact us today to discuss your project requirements!

Visual Guide

References

- Jérôme Mendonça, Renaud Podor. Development of a microfurnace dedicated to <i>in situ</i> scanning electron microscope observation up to 1300 °C. III. <i>In situ</i> high temperature experiments. DOI: 10.1063/5.0207477

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- In which industries is the vacuum carburizing furnace commonly used? Essential for Aerospace and High-Performance Machinery

- Why is a vacuum drying oven critical for moisture-sensitive batteries? Ensuring Stability in Potassium-Ion Systems

- What is the function of a soaking furnace in the heat treatment of steel rod bundles? Unlock Material Reliability

- What are the key differences in pumping systems between low vacuum and high vacuum furnaces? Choose the Right System for Your Process

- What role do vacuum furnaces play in electronic component manufacturing? Essential for Purity and Precision

- Why is the atmosphere control in Vacuum Furnaces essential? Unlock Precise High-Temperature Thermodynamic Insights

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the advantages of vacuum heat treatment? Achieve Superior Metallurgical Control and Pristine Surfaces