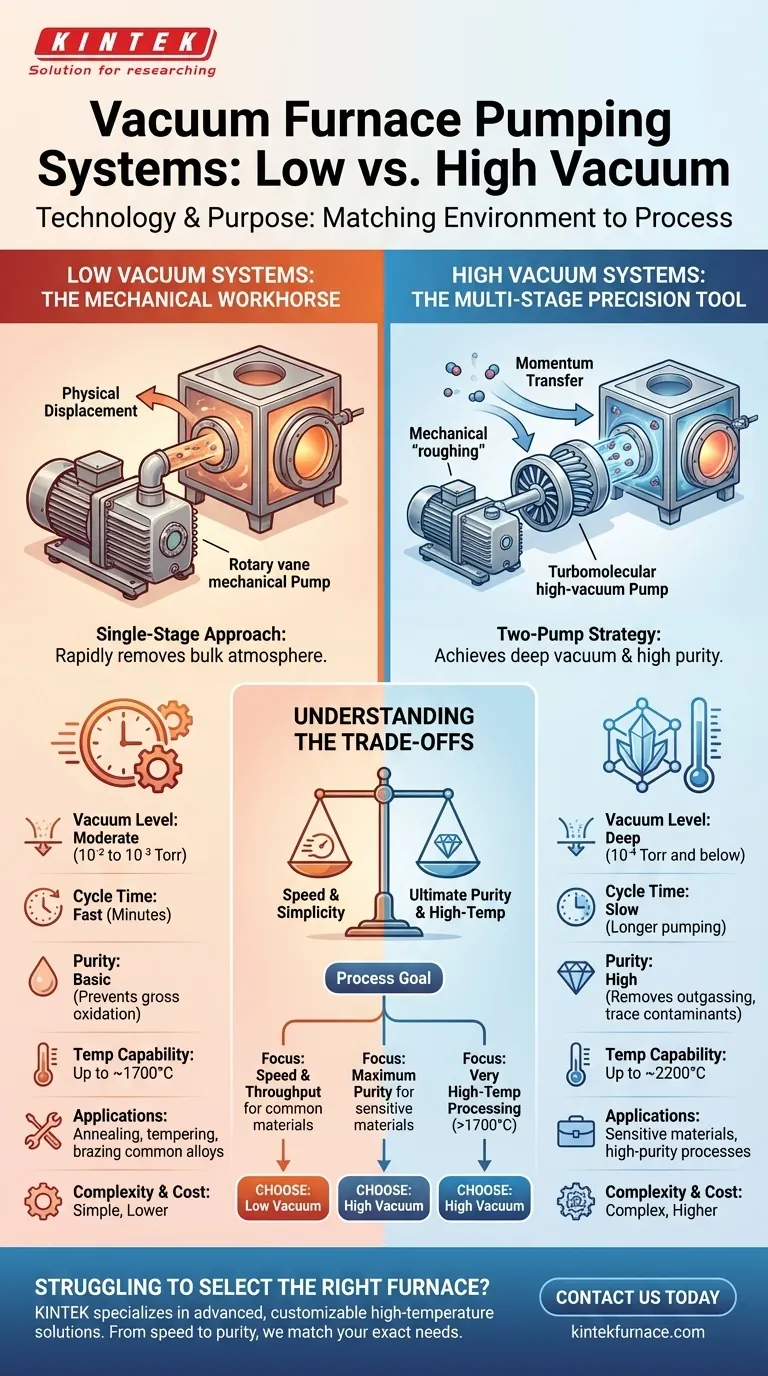

At its core, the difference between low and high vacuum furnace pumping systems is a matter of technology and purpose. Low vacuum furnaces use a single, robust mechanical pump to quickly remove the bulk of the atmosphere. High vacuum furnaces, in contrast, use a sophisticated multi-stage system, combining a mechanical "roughing" pump with a secondary high-vacuum pump to achieve a much deeper level of vacuum and purity.

Choosing between these systems is not about which is "better," but about matching the vacuum environment to your specific process requirements. The decision balances the need for speed and simplicity against the demand for ultimate purity and high-temperature performance.

The Purpose of a Vacuum Environment

Before comparing pumps, it's critical to understand why a vacuum is used. A vacuum furnace doesn't just remove air; it creates a tightly controlled, inert environment.

Removing Reactive Gases

The primary goal is to remove oxygen and other reactive gases. This prevents oxidation and contamination of the material being processed at high temperatures.

Improving Product Purity

By removing the atmosphere, the pumping system also pulls away byproducts and contaminants released from the material during heating. This is known as outgassing, and its removal results in a cleaner, higher-purity final product.

Low Vacuum Systems: The Mechanical Workhorse

Low vacuum furnaces are designed for processes where rapid cycling and basic atmosphere control are more important than achieving an extremely deep vacuum.

The Single-Stage Approach

These systems almost exclusively use a single mechanical pump, most commonly a rotary vane pump. This pump is connected directly to the furnace chamber.

How It Works: Physical Displacement

A mechanical pump works by physically trapping and compressing volumes of gas, moving them from the furnace chamber to the outside atmosphere. It is highly effective at removing the vast majority of air molecules quickly.

Common Applications

These furnaces are ideal for applications like annealing, tempering, and brazing common alloys where preventing gross oxidation is the main goal, and some level of atmospheric impurity is acceptable.

High Vacuum Systems: The Multi-Stage Precision Tool

High vacuum furnaces are required for sensitive materials or processes that demand an exceptionally clean environment, free from even trace amounts of atmospheric molecules.

The Two-Pump Strategy

These systems use a multi-stage approach. No single pump is efficient across the entire pressure range from atmosphere down to high vacuum.

Stage 1: The Roughing Pump

First, a mechanical pump (the "roughing" pump) does the initial work. It removes about 99.9% of the air, bringing the chamber to a low vacuum level, typically in the range of 10⁻² to 10⁻³ Torr.

Stage 2: The High-Vacuum Pump

Once the mechanical pump reaches its limit, a secondary pump takes over. This is usually a turbomolecular pump or a diffusion pump, which can operate only once a low vacuum has been established. These pumps are not effective at atmospheric pressure.

How They Work: Momentum Transfer

Unlike mechanical pumps, turbo and diffusion pumps work by imparting momentum to individual gas molecules, directing them out of the chamber. This method is far more effective at the extremely low pressures that define a high vacuum environment (10⁻⁴ Torr and below).

Understanding the Trade-offs

The choice of pumping system creates fundamental differences in furnace performance, capability, and complexity.

Cycle Time

Low vacuum furnaces have much faster cycle times. Their simple, powerful mechanical pumps can evacuate the chamber to the target pressure in minutes. High vacuum systems are slower, as achieving an ultra-low pressure requires significantly more pumping time.

Process Purity

A high vacuum system creates a vastly purer environment. By removing more molecules from the chamber, it drastically reduces the chance of reaction with sensitive materials like titanium or refractory metals, and it more effectively removes outgassed contaminants.

Temperature Capability

High vacuum furnaces can achieve significantly higher temperatures, often up to 2200°C, compared to the typical 1700°C limit for low vacuum models. The superior vacuum protects graphite heating elements and insulation from residual oxygen, which would cause them to rapidly degrade at extreme temperatures.

System Complexity and Cost

The multi-stage nature of high vacuum systems makes them inherently more complex, more expensive to purchase, and more demanding to maintain than their simpler low vacuum counterparts.

Making the Right Choice for Your Process

Your process goals will dictate which system is appropriate.

- If your primary focus is speed and throughput for common materials: A low vacuum atmosphere furnace is the efficient and cost-effective choice.

- If your primary focus is maximum purity for sensitive materials: A high vacuum system is non-negotiable to prevent contamination and ensure product quality.

- If your primary focus is very high-temperature processing (above 1700°C): A high vacuum furnace is required to protect the furnace components and ensure operational stability.

Ultimately, understanding this distinction empowers you to select not just a furnace, but the precise atmospheric environment your process demands.

Summary Table:

| Aspect | Low Vacuum Furnace | High Vacuum Furnace |

|---|---|---|

| Pumping System | Single mechanical pump (e.g., rotary vane) | Multi-stage system (mechanical roughing pump + high-vacuum pump like turbomolecular) |

| Vacuum Level | Moderate (e.g., 10⁻² to 10⁻³ Torr) | Deep (e.g., 10⁻⁴ Torr and below) |

| Cycle Time | Fast (minutes) | Slow (longer pumping time) |

| Process Purity | Basic, suitable for preventing oxidation | High, removes outgassing and contaminants |

| Temperature Capability | Up to ~1700°C | Up to ~2200°C |

| Applications | Annealing, tempering, brazing common alloys | Sensitive materials, high-purity processes, high-temperature processing |

| Complexity and Cost | Simple, lower cost | Complex, higher cost and maintenance |

Struggling to select the right vacuum furnace for your lab's unique needs? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our exceptional R&D and in-house manufacturing, we offer deep customization to precisely match your experimental requirements—whether you need the speed of a low vacuum system or the purity of a high vacuum setup. Contact us today to discuss how our tailored solutions can enhance your process efficiency and product quality!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- How do multi zone tube furnaces improve laboratory efficiency? Boost Throughput with Parallel Processing

- What is the maximum sample size that the 3-Zone tube furnace can accommodate? Optimize for Uniform Heating and CVD

- What are the benefits of integrating multiple heating zones in a tube furnace? Unlock Precise Thermal Control

- What preparations are needed before starting a multi zone tube furnace? Ensure Safety and Accuracy in Your Lab

- What are the advantages of individually temperature-controlled zones in multi-zone furnaces? Unlock Precision Thermal Gradients