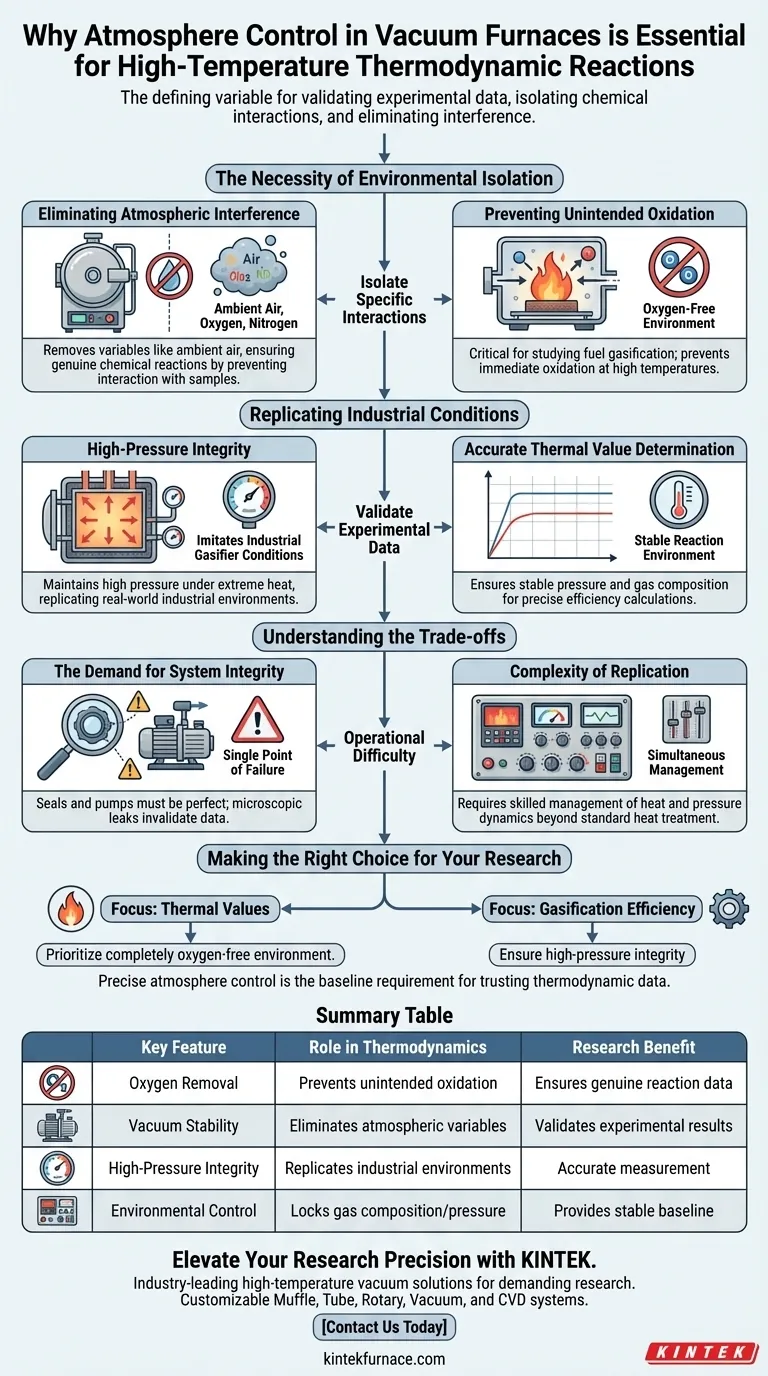

Atmosphere control is the defining variable that validates experimental data in high-temperature thermodynamics. It is essential because it allows researchers to isolate specific chemical interactions—specifically within fuel gasification—by creating a clean, oxygen-free, or precisely pressurized environment that eliminates external interference.

By maintaining a strictly controlled environment, vacuum furnaces prevent atmospheric contamination that would otherwise skew results. This precision is required to accurately determine the thermal value of gases and measure the efficiency of partial oxidation reactions.

The Necessity of Environmental Isolation

Eliminating Atmospheric Interference

In standard environments, the air we breathe creates variables that are impossible to calculate out of high-temperature experiments. Atmosphere control removes these variables entirely.

By utilizing a vacuum or specific gas mixtures, researchers ensure that the chemical reactions observed are genuine. This prevents ambient air from interacting with the sample and altering the thermodynamic outcome.

Preventing Unintended Oxidation

Oxygen is highly reactive at the temperatures required for thermodynamic studies. Without a vacuum or inert atmosphere, samples would oxidize immediately upon heating.

Vacuum furnaces create an oxygen-free environment. This is critical for studying fuel gasification, where the goal is to observe specific partial oxidation reactions without the interference of uncontrolled combustion.

Replicating Industrial Conditions

High-Pressure Integrity

Studying gasification is not just about temperature; it is also about pressure. Vacuum furnaces are designed to maintain high-pressure integrity while simultaneously subjecting samples to extreme heat.

This capability allows researchers to move beyond theoretical models. They can physically replicate the intense thermodynamic conditions found inside an industrial gasifier.

Accurate Thermal Value Determination

To determine the true thermal value of generated gases, the reaction environment must remain stable. Fluctuations in pressure or gas composition render these measurements void.

Atmosphere control systems lock in these variables. This stability allows for the precise calculation of how efficient a partial oxidation reaction truly is under specific constraints.

Understanding the Trade-offs

The Demand for System Integrity

The reliance on atmosphere control introduces a single point of failure. If the furnace cannot maintain high-pressure integrity, the experiment is not just flawed—it is useless.

Researchers must ensure that seals and pumps are functioning perfectly. Even a microscopic leak introduces oxygen or drops pressure, invalidating the "clean" status of the environment.

Complexity of Replication

Simulating a gasifier is significantly more complex than standard heat treatment. It requires the simultaneous management of high heat and specific gas pressures.

This increases the operational difficulty of the furnace. Users must be skilled in managing gas flow and pressure dynamics, not just temperature profiles, to achieve valid data.

Making the Right Choice for Your Research

To ensure your thermodynamic studies yield actionable data, align your equipment use with your specific experimental goals:

- If your primary focus is determining thermal values: Prioritize a setup that guarantees a completely oxygen-free environment to prevent pre-mature combustion of the gases.

- If your primary focus is gasification efficiency: Ensure your furnace can maintain high-pressure integrity to accurately mimic the stress conditions of a real-world gasifier.

Precise control of the atmosphere is not just a feature; it is the baseline requirement for trusting your thermodynamic data.

Summary Table:

| Key Feature | Role in Thermodynamics | Research Benefit |

|---|---|---|

| Oxygen Removal | Prevents unintended oxidation | Ensures genuine reaction data without combustion interference |

| Vacuum Stability | Eliminates atmospheric variables | Validates experimental results by isolating specific interactions |

| High-Pressure Integrity | Replicates industrial environments | Accurate measurement of gasification efficiency and thermal values |

| Environmental Control | Locks gas composition/pressure | Provides a stable baseline for calculating precise partial oxidation |

Elevate Your Research Precision with KINTEK

Don't let atmospheric interference compromise your thermodynamic data. KINTEK provides industry-leading high-temperature vacuum solutions engineered for the most demanding research environments. Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems designed to maintain flawless high-pressure integrity and oxygen-free conditions.

Whether you are studying fuel gasification or determining precise thermal values, our systems deliver the stability and control your lab requires. Contact us today to discuss your unique project needs and discover how our specialized furnace technology can optimize your scientific outcomes.

Visual Guide

References

- Shiwei Yu, Mingjie Feng. Workflow Design and Operational Analysis of a Coal‐Based Multi‐Energy Combined Supply System for Electricity, Heating, Cooling, and Gas. DOI: 10.1002/ese3.70137

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does vacuum brazing work? Achieve Superior Joint Integrity for Critical Applications

- What factors should be considered when choosing between a low vacuum and high vacuum furnace? Optimize Your Heat Treatment Process

- What are the main functions of vacuum furnaces? Achieve Superior Purity and Control in High-Temperature Processes

- What is the significance of using a vacuum diffusion annealing furnace for thermodynamic equilibrium studies in alloys?

- What are the key characteristics of vacuum hardening? Achieve Clean, Precise Metal Hardening for Superior Components

- What are the steps in the discharge plasma sintering process? Master Fast, High-Density Material Consolidation

- Why is vacuum brazing particularly useful in aerospace and other high-precision industries? Achieve Superior, Contamination-Free Joints

- Why is a high vacuum chamber system essential for the PLD of SrNbO3 thin films? Achieve High-Purity Epitaxial Growth