The choice between a low vacuum and a high vacuum furnace is determined by your material's sensitivity, your process's required purity, and your operational budget. A low vacuum system is a cost-effective solution for preventing general oxidation in robust materials, while a high vacuum furnace provides a meticulously controlled environment essential for processing reactive, high-value materials where any contamination is unacceptable.

The decision is not merely about the level of vacuum you can achieve. It's a strategic choice between preventing basic surface reactions (low vacuum) and achieving ultimate chemical purity by eliminating virtually all reactive molecules and degassing the material itself (high vacuum).

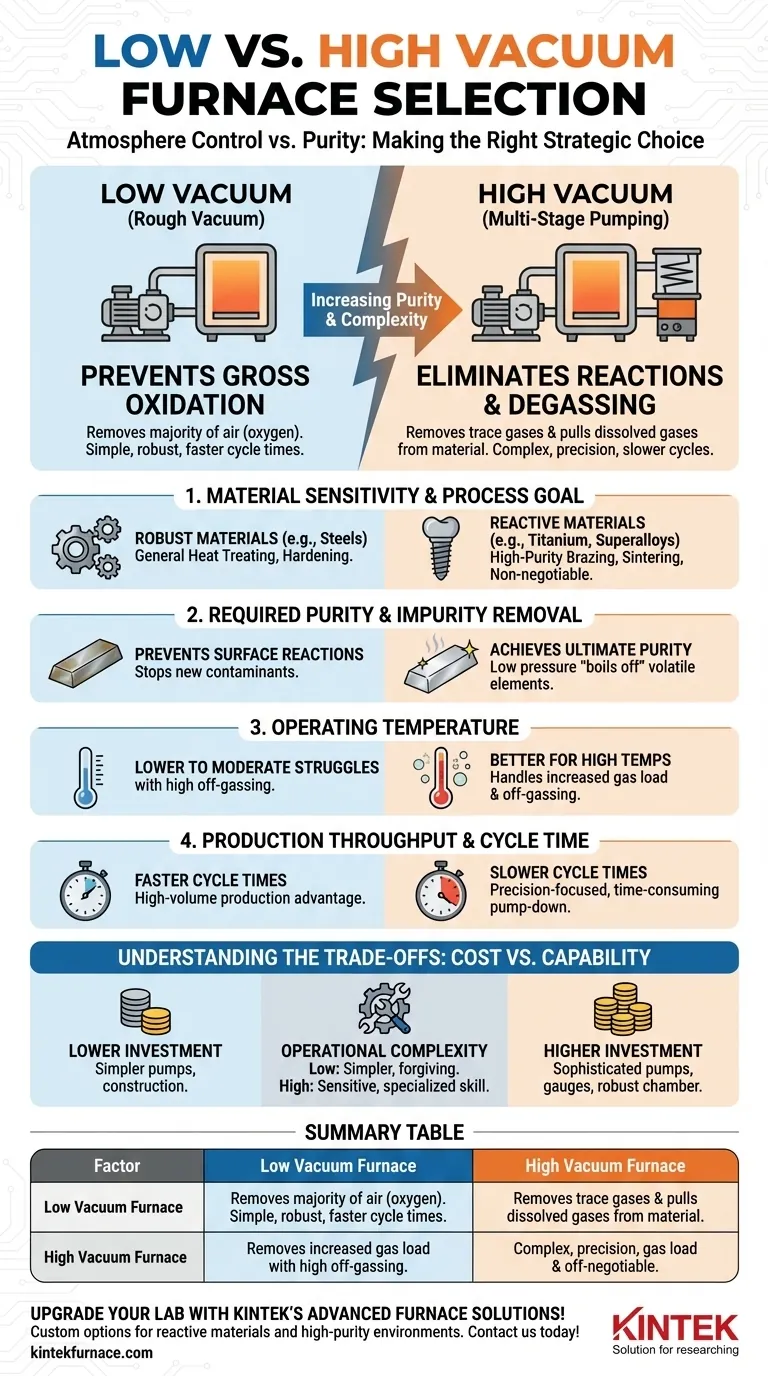

The Fundamental Difference: Atmosphere Control vs. Purity

The terms "low vacuum" and "high vacuum" represent two distinct philosophies of atmosphere management. Understanding this difference is the key to making the right investment.

Low Vacuum: Preventing Gross Oxidation

A low vacuum (or "rough vacuum") system is designed to remove the vast majority of air, primarily oxygen, from the furnace chamber. Its main purpose is to prevent large-scale oxidation, discoloration, and scaling on the surface of the parts being heat-treated.

These systems are mechanically simpler, typically using only rotary vane or similar mechanical pumps. They are robust, reliable, and offer faster cycle times because the target pressure is relatively easy to achieve.

High Vacuum: Eliminating Reactions and Degassing

A high vacuum system goes much further. It uses a multi-stage pumping system (combining mechanical pumps with diffusion or turbomolecular pumps) to remove not just oxygen, but also trace gases like water vapor, nitrogen, and argon.

The goal is to create an environment so inert that it prevents even microscopic reactions. Crucially, a high vacuum can also pull dissolved gases out of the material itself, a process known as degassing. This is critical for achieving the highest possible material purity and integrity.

Key Decision Factors Breakdown

Your process requirements will point directly to the correct vacuum level. Analyze your application against these four critical factors.

1. Material Sensitivity and Process Goal

This is the most important consideration. For general-purpose heat treating of steels or less reactive alloys where the primary goal is hardening or stress-relieving, a low vacuum is often sufficient.

For processing highly reactive materials like titanium, zirconium, and refractory metals, a high vacuum is non-negotiable. These materials can be contaminated and embrittled by even trace amounts of oxygen or nitrogen, especially at high temperatures. Processes like high-purity brazing, medical implant manufacturing, and aerospace component sintering demand a high vacuum environment.

2. Required Purity and Impurity Removal

If your process requires removing volatile elements from a material, you need a high vacuum system. The low pressure effectively lowers the boiling point of these impurities, causing them to "boil off" the material and be removed by the vacuum pumps.

Low vacuum systems do not generate enough pressure differential to facilitate this kind of purification. They only prevent new contaminants from being introduced from the atmosphere.

3. Operating Temperature

The higher the process temperature, the more reactive materials become and the more they tend to off-gas (release trapped gases from their surface).

A high vacuum system is better equipped to handle this increased gas load while maintaining the necessary low pressure. A low vacuum system may struggle to keep up, allowing the partial pressure of reactive gases to rise and compromise the process.

4. Production Throughput and Cycle Time

Achieving a high vacuum is a time-consuming process. The pump-down sequence can add significant time to each furnace cycle compared to a low vacuum system.

If your operation prioritizes high-volume production of less sensitive components, the faster cycle times of a low vacuum furnace offer a clear throughput advantage.

Understanding the Trade-offs: Cost vs. Capability

Choosing a furnace is a major capital investment, and the difference in cost and complexity between low and high vacuum systems is substantial.

Initial Investment

High vacuum furnaces are significantly more expensive. The cost is driven by the need for a sophisticated two-stage pumping system, more advanced controllers and gauges (e.g., ion gauges), and more robust chamber construction to handle the extreme pressure differential.

Operational Complexity and Maintenance

Low vacuum systems are the workhorses of the heat-treating world. They are mechanically simpler, more forgiving of small leaks, and require less specialized knowledge to operate and maintain.

High vacuum systems are precision instruments. They are extremely sensitive to leaks, require meticulous cleaning protocols to avoid contamination, and demand more highly skilled technicians for operation and maintenance.

Energy and Consumables

While the furnace heating elements are a primary energy consumer, the complex pumping system of a high vacuum furnace adds to the overall energy draw. Furthermore, specialized pumps may require consumables like pump oil that add to the ongoing operational cost.

Making the Right Choice for Your Application

Answering this question requires a clear-eyed assessment of your process goals. Use these guidelines to make a definitive choice.

- If your primary focus is general heat treating and preventing surface discoloration (e.g., steel annealing, tempering): A low vacuum furnace is your most cost-effective and efficient solution.

- If your primary focus is joining or processing highly reactive materials (e.g., titanium, superalloys, refractory metals): A high vacuum furnace is mandatory to prevent material contamination and ensure structural integrity.

- If your primary focus is achieving maximum material purity and degassing (e.g., medical implants, vacuum electronics, R&D): You must invest in a high vacuum system to remove volatile contaminants from the material itself.

- If your primary focus is high-volume production with moderate quality needs: The faster cycle times of a low vacuum system will provide a significant throughput advantage that justifies its selection.

By aligning your furnace choice with the fundamental requirements of your material and process, you turn a major purchase into a strategic investment in quality and operational efficiency.

Summary Table:

| Factor | Low Vacuum Furnace | High Vacuum Furnace |

|---|---|---|

| Material Sensitivity | Suitable for robust materials (e.g., steels) | Essential for reactive materials (e.g., titanium, superalloys) |

| Purity Requirements | Prevents surface oxidation | Achieves high purity and degassing |

| Operating Temperature | Handles lower to moderate temperatures | Better for high temperatures with off-gassing |

| Production Throughput | Faster cycle times, higher volume | Slower cycle times, precision-focused |

| Cost and Complexity | Lower initial cost, simpler operation | Higher initial cost, more complex maintenance |

Upgrade your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with tailored options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, whether you're processing reactive materials or requiring high-purity environments. Don't let furnace limitations hold you back—contact us today to discuss how we can enhance your efficiency and results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties