A high vacuum chamber system is the non-negotiable foundation for the successful Pulsed Laser Deposition (PLD) of Strontium Niobate ($SrNbO_3$) thin films. It creates an ultra-clean environment that prevents residual gas molecules from physically interfering with the deposition process and chemically altering the material.

Without this high vacuum baseline, it is impossible to regulate the delicate oxygen balance required to stabilize the Niobium ions, leading to degraded film quality and incorrect physical properties.

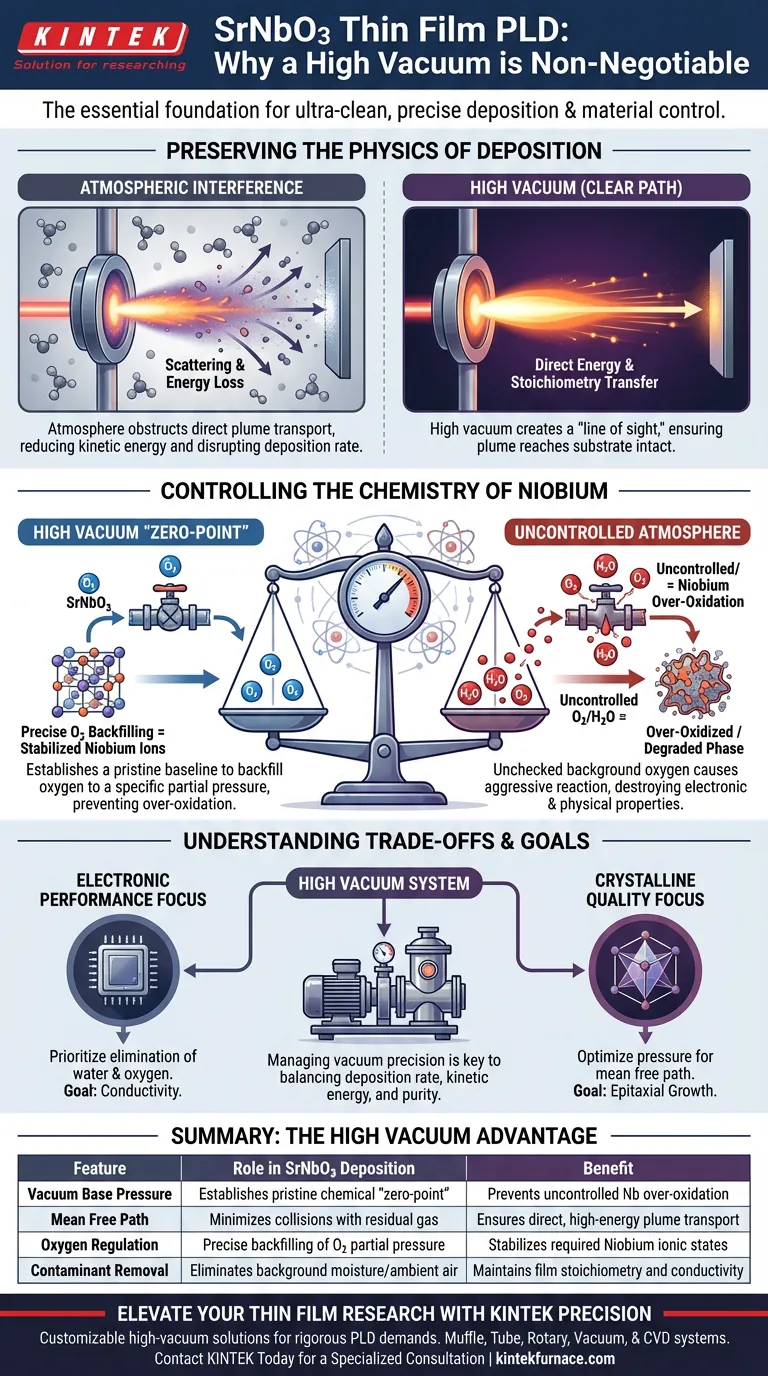

Core Takeaway: The high vacuum system serves two simultaneous functions: it clears the physical path for the laser-generated plasma plume to reach the substrate without scattering, and it establishes a "zero-point" environment that allows for the precise addition of oxygen. This control is the only way to prevent the over-oxidation of Niobium, which determines the film's final utility.

Preserving the Physics of Deposition

To understand why vacuum is essential, one must first look at the physical transport of material from the target to the substrate.

Minimizing Molecular Interference

In an atmospheric environment, the space between the laser target and the substrate is crowded with gas molecules. A high vacuum removes these obstacles, creating a clear "line of sight" for the deposition.

Preventing Plume Scattering

When the laser ablates the $SrNbO_3$ target, it creates a plasma plume. If this plume collides with residual gas molecules, the material scatters.

This scattering reduces the kinetic energy of the atoms and disrupts the deposition rate. A high vacuum ensures the plume transmits directly to the substrate with its energy and stoichiometry intact.

Controlling the Chemistry of Niobium

The deep need for a high vacuum in this specific application revolves around the chemical reactivity of the material itself, particularly Niobium ($Nb$).

Strict Control of Oxygen Partial Pressure

$SrNbO_3$ is an oxide, but it requires a very specific oxidation state to function correctly.

A high vacuum system creates a pristine baseline, allowing researchers to backfill oxygen to a precise partial pressure. You cannot achieve this control if you are fighting against random atmospheric oxygen levels.

Preventing Niobium Over-Oxidation

Niobium ions are highly susceptible to oxidation. If the background environment contains uncontrolled oxygen or moisture, the Niobium will react aggressively.

This leads to over-oxidation, pushing the material away from the desired $SrNbO_3$ phase. This chemical shift destroys the intended electronic and physical properties of the epitaxial film.

Understanding the Trade-offs

While essential for quality, utilizing high vacuum systems introduces specific constraints that must be managed.

Operational Complexity vs. Purity

Achieving high vacuum requires sophisticated pumping systems (often turbomolecular pumps) and strict seal integrity. This increases the complexity and maintenance requirements of the equipment compared to non-vacuum deposition methods.

Deposition Rate vs. Kinetic Energy

While vacuum prevents scattering, extremely high vacuum can sometimes lead to highly energetic particle bombardment on the substrate.

This is why the ability to control background pressure is key; it allows you to balance the mean free path of the particles to prevent substrate damage while ensuring film density.

Making the Right Choice for Your Goal

The level of vacuum precision you maintain dictates the specific qualities of your final film.

- If your primary focus is Electronic Performance: Prioritize the elimination of background water vapor and oxygen to prevent Nb over-oxidation, which creates insulating rather than conductive phases.

- If your primary focus is Crystalline Quality: Focus on maintaining a pressure that maximizes the mean free path, ensuring the plasma plume arrives at the substrate with sufficient energy for epitaxial growth.

Mastering the vacuum environment is the first step toward mastering the material properties of Strontium Niobate.

Summary Table:

| Feature | Role in SrNbO3 Deposition | Benefit |

|---|---|---|

| Vacuum Base Pressure | Establishes a pristine chemical "zero-point" | Prevents uncontrolled Nb over-oxidation |

| Mean Free Path | Minimizes collisions with residual gas | Ensures direct, high-energy plume transport |

| Oxygen Regulation | Precise backfilling of O2 partial pressure | Stabilizes required Niobium ionic states |

| Contaminant Removal | Eliminates background moisture/ambient air | Maintains film stoichiometry and conductivity |

Elevate Your Thin Film Research with KINTEK Precision

Don't let atmospheric interference compromise your $SrNbO_3$ research. KINTEK provides high-performance, customizable high-vacuum solutions designed specifically for the rigorous demands of Pulsed Laser Deposition (PLD).

Backed by expert R&D and world-class manufacturing, we offer a full range of Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your unique lab high-temp needs. Ensure perfect stoichiometry and crystalline quality for your next project.

Contact KINTEK Today for a Specialized Consultation

Visual Guide

References

- Haitao Hong, Er‐Jia Guo. Metal‐to‐insulator transition in oxide semimetals by anion doping. DOI: 10.1002/idm2.12158

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- Why is a Vacuum Drying Oven necessary for KF-NaF-AlF3 electrolytes? Prevent Hydrolysis and Corrosion

- Why is short-term annealing followed by water quenching necessary for Ti-15Mo alloys? Lock in Peak Material Performance

- How does indirect gas heating contribute to vacuum furnace efficiency? Lower Costs and Boost ROI

- What is vacuum brazing and how does it differ from traditional brazing? Discover Superior Joint Integrity

- What role do laboratory high-temperature furnaces play in the growth of Ni3In2Se2 single crystals? Precision Growth Control

- What is the principle of graphite furnace? Master Ultra-Trace Element Analysis with Precise Heating

- What is the function of a vacuum annealing furnace for Cu/CuFeO2/CZTS films? Enhancing Solar Cell Heterojunctions

- What are the benefits of using a vacuum drying oven for sensitive ceramic materials? Unlock Unmatched Material Purity