At its core, vacuum brazing is a high-purity joining process that uses a vacuum furnace to create a bond between components. Unlike traditional brazing, which relies on a chemical flux to clean the metal surfaces, vacuum brazing removes the atmospheric oxygen that causes oxidation. This elimination of flux results in cleaner, stronger, and more reliable joints, especially for high-performance applications.

The fundamental difference isn't the joining material, but the environment. Traditional brazing fights oxidation with a chemical flux, while vacuum brazing prevents oxidation from ever occurring by removing the air itself.

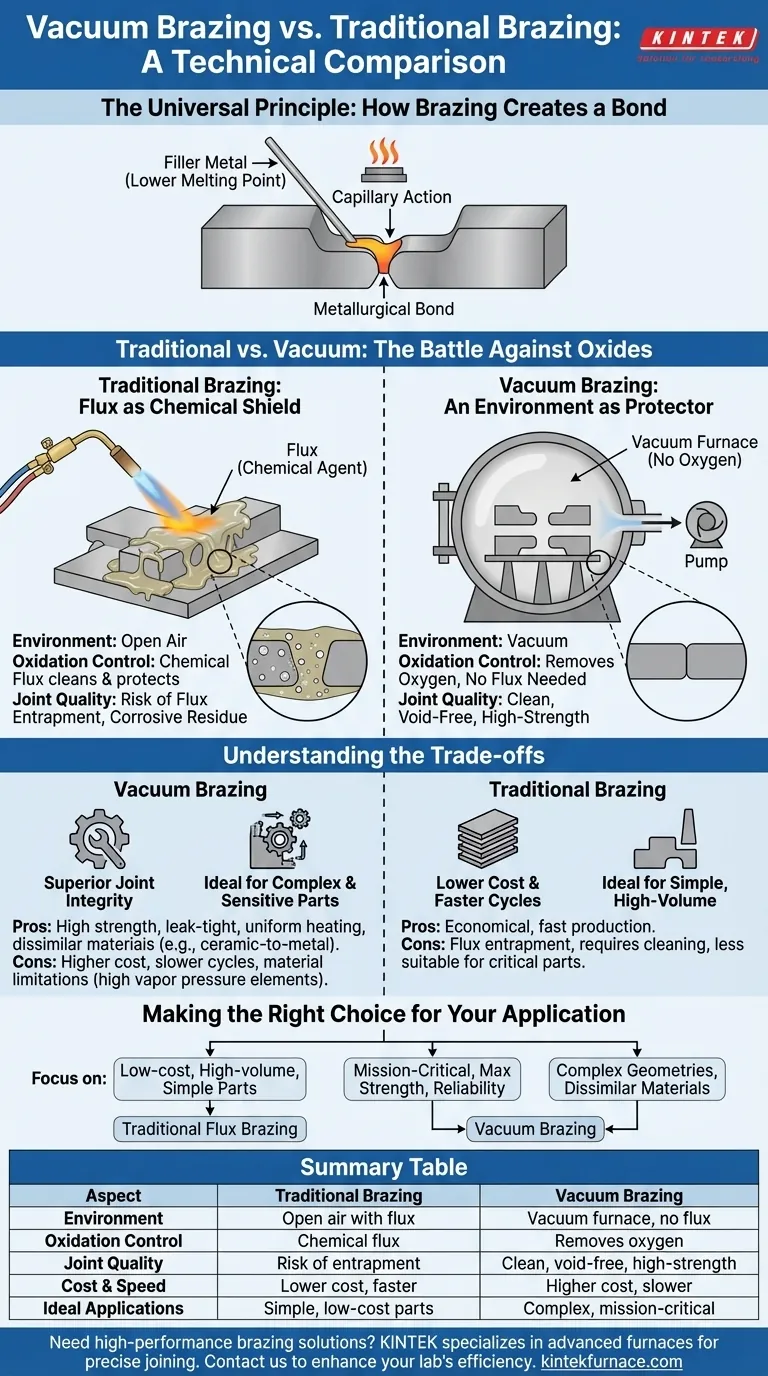

The Universal Principle: How Brazing Creates a Bond

To understand the difference, we must first recognize what all brazing methods have in common. The goal is to join materials without melting them.

The Role of Filler Metal

Brazing uses a filler metal with a lower melting point than the base materials being joined. This filler is placed along the joint interface.

The assembly is heated to a temperature above the filler's melting point but below the base materials' melting point. The filler liquefies and flows, while the parent components remain solid.

The Power of Capillary Action

Once molten, the filler metal is drawn into the tight-fitting gap between the components through a process called capillary action.

Upon cooling, the filler solidifies, forming a strong, permanent metallurgical bond that holds the assembly together.

Traditional vs. Vacuum: The Battle Against Oxides

The primary challenge in any high-temperature metal process is oxidation. The way each method handles this challenge is what truly separates them.

The Traditional Method: Flux as a Chemical Shield

In traditional brazing, the process is done in open air. To prevent the hot metal from oxidizing, a chemical agent called flux is applied to the joint.

Flux serves two purposes: it cleans any existing oxides from the surface and forms a protective barrier to prevent new oxides from forming during heating.

However, flux can become trapped in the joint, creating weak spots. It also leaves behind a corrosive residue that must be thoroughly cleaned after brazing, adding an extra, often difficult, step.

The Vacuum Method: An Environment as the Protector

Vacuum brazing takes a fundamentally different approach. The entire assembly is sealed inside a vacuum furnace.

By pumping out the air, the process removes the oxygen. Without oxygen, oxides simply cannot form on the metal surfaces, even at extreme temperatures (often 800°C to 1200°C).

This makes the use of flux completely unnecessary. The result is an exceptionally clean surface that allows the filler metal to bond directly and completely with the parent materials.

Understanding the Trade-offs

Choosing vacuum brazing is a decision based on performance requirements versus cost and complexity. It is not always the right tool for every job.

Superior Joint Integrity

The primary advantage of vacuum brazing is the quality of the joint. With no flux to risk entrapment, the bond is free of voids and impurities, leading to significantly higher strength and leak-tightness.

Ideal for Complex and Sensitive Parts

The process provides extremely uniform heating and cooling in a controlled environment. This makes it perfect for intricate assemblies, thin-walled components, or joining dissimilar materials like ceramic-to-metal or reactive metals like aluminum and titanium.

Higher Costs and Slower Cycles

Vacuum furnaces represent a significant capital investment. The process is also inherently slower than traditional brazing due to the time required to pump down the vacuum and safely cool the parts. This makes it less suitable for low-cost, high-volume manufacturing.

Limitations on Materials

Some materials with a high vapor pressure (like zinc, lead, or cadmium) are not suitable for vacuum brazing. At high temperatures and low pressures, these elements can vaporize out of the alloy, altering its composition and contaminating the furnace.

Making the Right Choice for Your Application

Selecting the correct brazing method depends entirely on the technical and commercial demands of your project.

- If your primary focus is low-cost, high-volume production of simple parts: Traditional flux brazing is typically the more economical and faster choice.

- If your primary focus is mission-critical components requiring maximum strength and reliability: Vacuum brazing is the definitive choice for its clean, void-free joints.

- If your primary focus is joining complex geometries or dissimilar materials: Vacuum brazing offers a level of control and cleanliness that traditional methods cannot match.

Ultimately, understanding the role of the environment is the key to choosing the right process for achieving your design goal.

Summary Table:

| Aspect | Traditional Brazing | Vacuum Brazing |

|---|---|---|

| Environment | Open air with flux | Vacuum furnace, no flux |

| Oxidation Control | Uses chemical flux to clean and protect | Removes oxygen to prevent oxidation |

| Joint Quality | Risk of flux entrapment and residue | Clean, void-free, high-strength joints |

| Cost and Speed | Lower cost, faster for high-volume | Higher cost, slower due to vacuum cycles |

| Ideal Applications | Simple parts, low-cost production | Complex geometries, dissimilar materials, mission-critical parts |

Need high-performance brazing solutions for your laboratory? KINTEK specializes in advanced high-temperature furnaces, including Vacuum & Atmosphere Furnaces, designed for precise, reliable joining processes. With our deep customization capabilities, we can tailor solutions to meet your unique experimental needs. Contact us today to enhance your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing