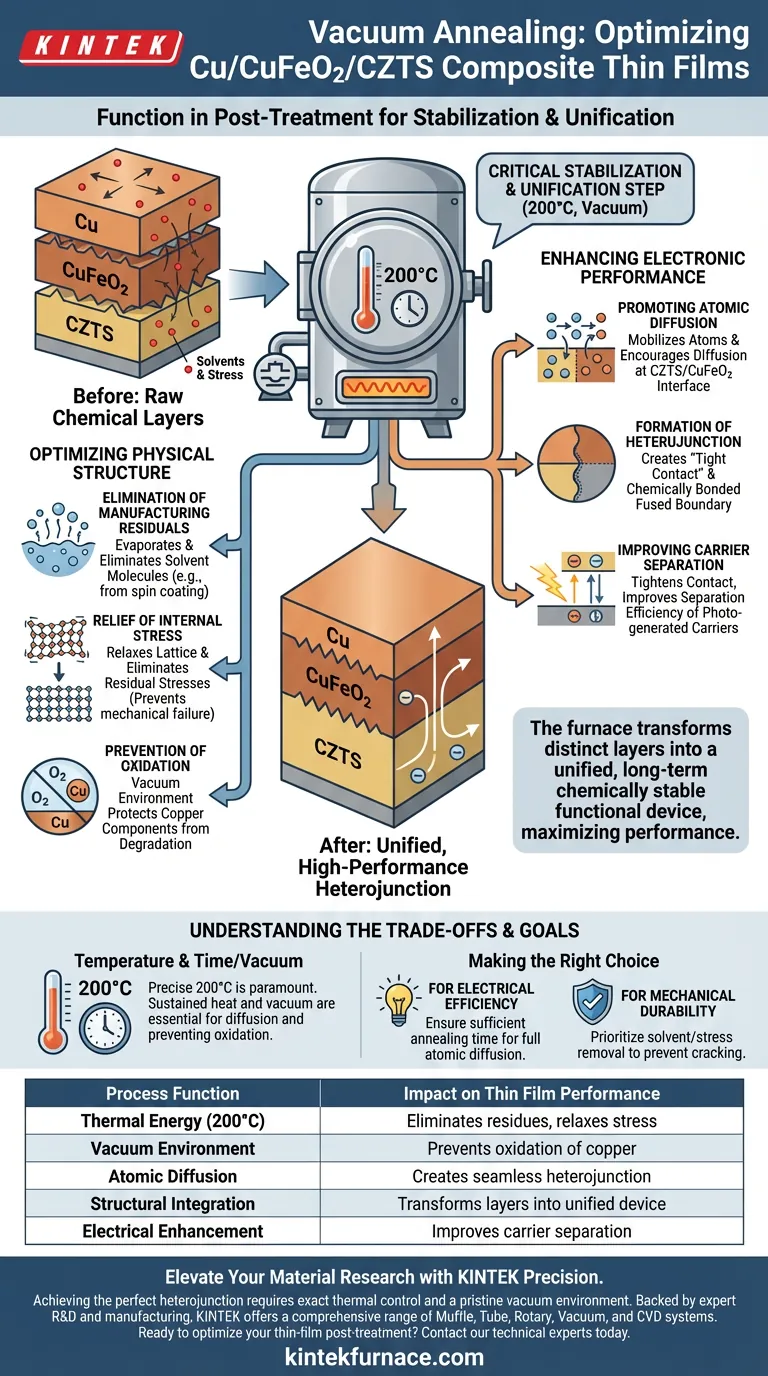

Vacuum annealing acts as a critical stabilization and unification step for Cu/CuFeO2/CZTS composite thin films. Operating at 200°C, the furnace provides thermal energy to remove volatile manufacturing byproducts and relax physical tension within the material. Simultaneously, it drives atomic movement between layers to create a seamless electrical interface.

The primary function of this process is to transform distinct coated layers into a unified, high-performance heterojunction. By promoting atomic diffusion, the furnace maximizes the film's ability to separate photo-generated carriers and ensures long-term chemical stability.

Optimizing the Physical Structure

Elimination of Manufacturing Residuals

The thin films are typically created using solution-based methods like spin coating, which leave behind liquid residues. The vacuum annealing furnace uses thermal energy to effectively evaporate and eliminate solvent molecules trapped within the layers.

Relief of Internal Stress

During the deposition process, the material often develops significant internal tension. The 200°C thermal treatment allows the lattice to relax, eliminating residual stresses that could otherwise lead to mechanical failure or delamination.

Prevention of Oxidation

While the primary focus is thermal treatment, the vacuum environment plays a subtle but vital role. By excluding oxygen, the furnace protects the metal components within the composite from degrading during the heating phase.

Enhancing Electronic Performance

Promoting Atomic Diffusion

The uniform thermal field provided by the furnace does more than just dry the film; it mobilizes the atoms. This heat encourages atomic diffusion specifically at the interface between the CZTS and CuFeO2 layers.

Formation of the Heterojunction

This diffusion creates a "tight contact" between the materials, chemically bonding them rather than just having them sit on top of one another. This fused boundary is known as a heterojunction, which is the functional core of the composite device.

Improving Carrier Separation

A high-quality heterojunction is essential for the film's electrical performance. By tightening this contact, the furnace improves the separation efficiency of photo-generated carriers, allowing the material to convert light into electricity more effectively.

Understanding the Trade-offs

Temperature Sensitivity

Precise temperature control is paramount; the process described relies specifically on a 200°C operational point. While other materials (such as ferroelectrics or alloys) require much higher temperatures (up to 1000°C) to crystallize, this specific composite requires a lower temperature to fuse layers without damaging the delicate chemical balance.

The Role of Time and Vacuum

The process is not instantaneous. It requires a sustained thermal environment to allow sufficient time for atomic diffusion. Furthermore, without a high-quality vacuum, the heat required to fix the interface would likely oxidize the copper components, destroying the film's conductive properties.

Making the Right Choice for Your Goal

To maximize the performance of your Cu/CuFeO2/CZTS films, align your post-treatment strategy with your specific objectives:

- If your primary focus is Electrical Efficiency: Ensure the annealing time is sufficient to fully promote atomic diffusion, as the tight heterojunction directly correlates to carrier separation.

- If your primary focus is Mechanical Durability: Prioritize the removal of solvents and residual stress to prevent cracking or delamination during long-term use.

Ultimately, the vacuum annealing furnace converts a stack of raw chemical layers into a stable, integrated functional device.

Summary Table:

| Process Function | Impact on Thin Film Performance |

|---|---|

| Thermal Energy (200°C) | Eliminates solvent residues and relaxes internal lattice stress. |

| Vacuum Environment | Prevents oxidation of copper components during the heating phase. |

| Atomic Diffusion | Creates a seamless, high-performance heterojunction at the interface. |

| Structural Integration | Transforms distinct layers into a unified, stable functional device. |

| Electrical Enhancement | Improves photo-generated carrier separation for higher efficiency. |

Elevate Your Material Research with KINTEK Precision

Achieving the perfect heterojunction requires exact thermal control and a pristine vacuum environment. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are working on thin-film solar cells or advanced alloy crystallization, our lab high-temp furnaces are fully customizable to meet your unique research needs.

Ready to optimize your thin-film post-treatment? Contact our technical experts today to find the ideal thermal solution for your lab!

Visual Guide

References

- Amira H. Ali, Mohamed Rabia. Synthesis of lead-free Cu/CuFeO2/CZTS thin film as a novel photocatalytic hydrogen generator from wastewater and solar cell applications. DOI: 10.1007/s11082-024-06375-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the purpose of utilizing a high vacuum system and vacuum sealing? Ensure Purity in Alloy Synthesis

- What is unique about the heating mechanism of a Spark Plasma Sintering (SPS) furnace when preparing nanostructured h-BN ceramics? Achieve Ultra-Fast Densification and Suppress Grain Growth

- What types of components are commonly made from graphite for vacuum furnace applications? Discover High-Temp Solutions

- How does a high-pressure gas quenching system maintain dimensional stability? Mastering Uniform Cooling Precision

- Why is it necessary to maintain a pressure below 6.7 Pa during stainless steel refining? Achieve Ultra-High Purity

- How does the evacuation process work in a vacuum furnace? Achieve Precise Metallurgical Control

- Why is vacuum sublimation preferred over recrystallization for MTO? Achieve High-Purity Methyltrioxorhenium

- What is the function of a soaking furnace in the heat treatment of steel rod bundles? Unlock Material Reliability