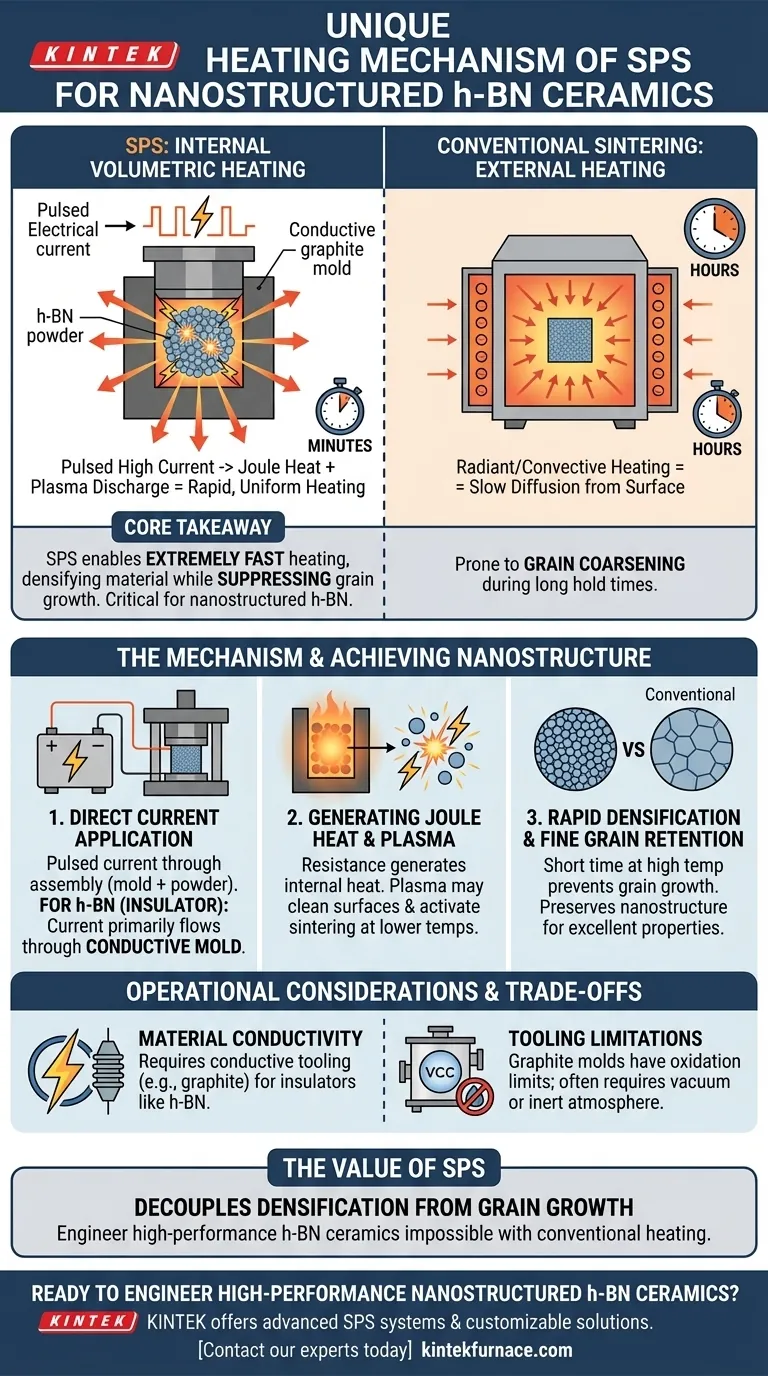

The unique characteristic of the heating mechanism in Spark Plasma Sintering (SPS) is the application of a pulsed high current directly through a conductive mold or the powder itself. This process generates internal volumetric heat via Joule heating and potential plasma discharges between particles, distinct from the radiant or convective heating used in conventional furnaces.

Core Takeaway Conventional sintering heats materials from the outside in, often leading to grain coarsening during long hold times. SPS solves this by generating heat internally, allowing for extremely fast heating rates that densify the material while suppressing grain growth, which is critical for maintaining nanostructured h-BN.

The Mechanism: Internal Volumetric Heating

Direct Current Application

Unlike traditional methods that rely on external heating elements, SPS utilizes pulsed high current.

This current is passed directly through the sintering assembly, which typically consists of the powder and a conductive mold (often graphite).

Generating Joule Heat

Because the current passes through the assembly, the electrical resistance of the mold and powder generates Joule heat.

This results in a "volumetric" heating effect, where the material is heated uniformly from within rather than waiting for heat to diffuse from the surface to the core.

The Role of Plasma Discharge

The mechanism may also involve the generation of plasma discharge between particles.

This phenomenon helps clean particle surfaces and activate sintering at lower temperatures, further enhancing the efficiency of the process.

Achieving Nanostructure through Speed

Rapid Heating Rates

The primary advantage of internal volumetric heating is the ability to achieve extremely fast heating rates.

The system can ramp up to high temperatures in minutes rather than the hours required by conventional sintering.

Suppressing Grain Growth

For nanostructured h-BN ceramics, the critical challenge is densifying the material without allowing the microscopic grains to grow larger (coarsen).

SPS addresses this by minimizing the time the material spends at high temperatures.

Fine Grain Retention

By completing the sintering process in a short time, SPS effectively suppresses grain growth.

This preserves the fine grain structure of the starting powder, resulting in ceramics with excellent mechanical properties.

Operational Considerations and Trade-offs

Material Conductivity

A key constraint is the requirement for electrical conductivity in the tooling or material.

Since h-BN is typically an electrical insulator, the pulsed current primarily flows through the conductive mold to generate the necessary heat, rather than through the powder itself.

Tooling Limitations

The conductive molds used in SPS (typically graphite) have oxidation limits.

This often necessitates sintering in a vacuum or inert atmosphere, which adds complexity compared to air-sintering furnaces.

Making the Right Choice for Your Goal

While SPS offers distinct advantages for nanostructured materials, understanding your specific requirements is essential.

- If your primary focus is maintaining nanostructure: Use SPS to leverage rapid heating rates that densify the ceramic before grains have time to coarsen.

- If your primary focus is process speed: Rely on the internal volumetric heating of SPS to significantly reduce cycle times compared to conventional hot pressing.

Ultimately, the value of SPS lies in its ability to decouple densification from grain growth, allowing you to engineer high-performance h-BN ceramics that are impossible to produce via conventional heating.

Summary Table:

| Feature | Spark Plasma Sintering (SPS) | Conventional Sintering |

|---|---|---|

| Heating Mechanism | Internal volumetric heating via pulsed current | External radiant/convective heating |

| Heating Rate | Extremely fast (minutes) | Slow (hours) |

| Grain Growth Control | Excellent suppression of grain growth | Prone to grain coarsening |

| Primary Advantage | Decouples densification from grain growth | Simpler tooling, can sinter in air |

Ready to Engineer High-Performance Nanostructured h-BN Ceramics?

Conventional furnaces struggle to densify materials without sacrificing nanostructure. The unique internal heating of Spark Plasma Sintering is the key to achieving ultra-fast densification while effectively suppressing grain growth.

Backed by expert R&D and manufacturing, KINTEK offers advanced SPS systems, alongside our Muffle, Tube, Rotary, Vacuum, and CVD furnaces. Our solutions are fully customizable to meet your unique research and production needs, empowering you to create materials with impossible properties.

Contact our experts today to discuss how an SPS furnace can unlock the next level of performance for your ceramics!

Visual Guide

Related Products

- Spark Plasma Sintering SPS Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What core role does a high-temperature vacuum sintering furnace play in Sm:YAG ceramics? Mastering Optical Clarity

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- What are the advantages of all-felt insulation? Boost Efficiency & Precision in High-Temp Processes

- What components make up the vacuum system of a vacuum furnace? Unlock Precision for High-Temperature Processing

- How does the annealing furnace process work? Master Material Softening and Stress Relief

- How does a vacuum brazing furnace prevent oxidation during the heating process? Achieve Clean, Strong Joints with Oxidation-Free Brazing

- How are active connection parts in a vacuum furnace sealed? Discover the Role of O-Rings and Water Cooling

- What are some applications of graphite materials in vacuum furnace processing? Discover Key Uses and Benefits