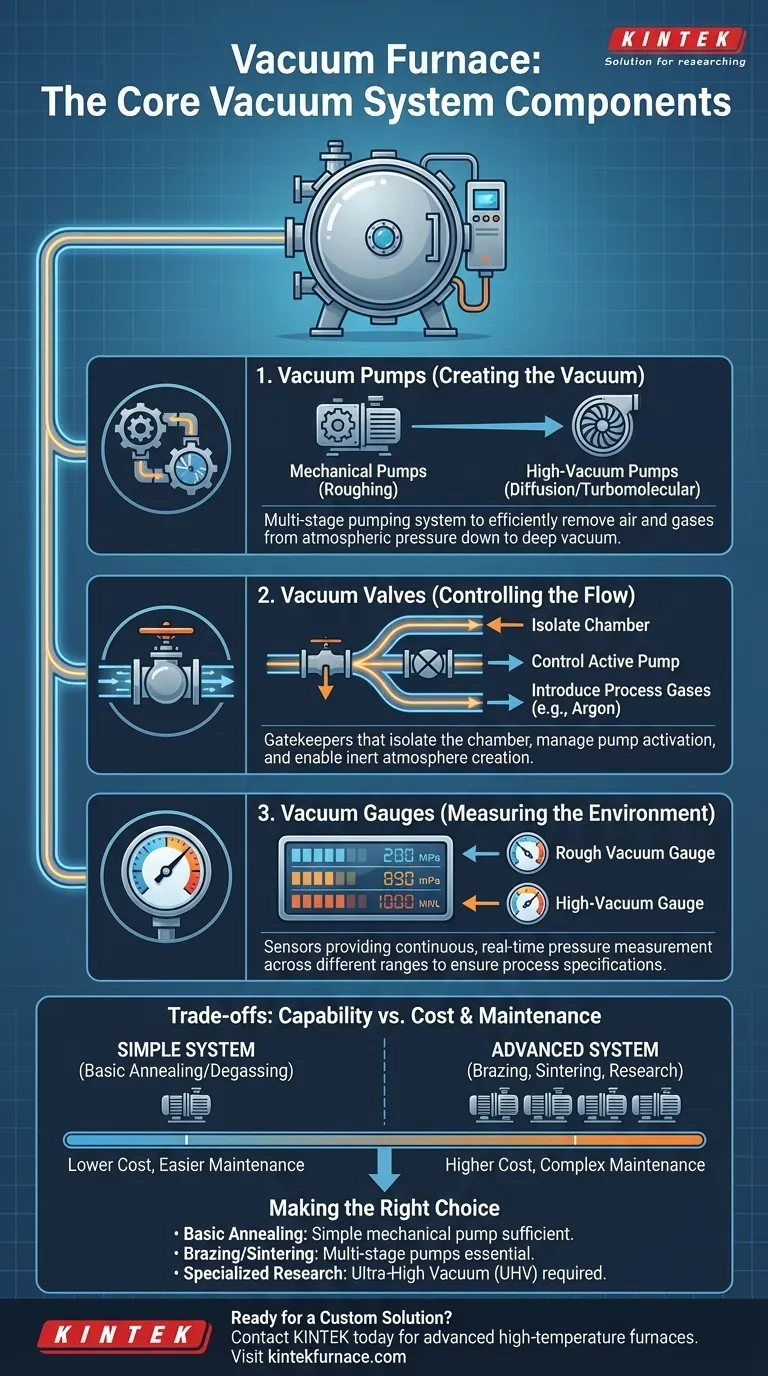

At its core, a vacuum furnace's vacuum system consists of three essential components. These are the vacuum pumps that remove air and gases, the vacuum valves that control the flow and isolate the chamber, and the vacuum gauges that measure the pressure. This trio works in concert to create the precisely controlled, sub-atmospheric environment required for high-temperature material processing.

The vacuum system is not merely an accessory; it is the functional heart of a vacuum furnace. Its purpose is to actively create, control, and verify a contamination-free environment, enabling processes that are impossible in the presence of air.

The Role of the Vacuum System

A standard furnace heats materials in the presence of air. A vacuum furnace is fundamentally different because it first removes that air. This seemingly simple act is critical for advanced manufacturing and material science.

The vacuum system is responsible for creating this unique processing environment, which prevents oxidation and removes impurities that would otherwise compromise the material's integrity at high temperatures.

Deconstructing the Core Components

While the system can be summarized by three categories, the specific components within each determine the furnace's ultimate capability.

The Pumping System: Creating the Vacuum

The "pump" is rarely a single device. Most furnaces use a multi-stage pumping system to efficiently remove gases from the chamber, moving from atmospheric pressure down to a deep vacuum.

These stages often include:

- Mechanical Pumps: Often called "roughing pumps," these are the workhorses that do the initial work of removing the bulk of the air from the chamber.

- High-Vacuum Pumps: Once the mechanical pump has reached its limit, a secondary pump takes over. This could be a diffusion pump or a turbomolecular pump, which can achieve much lower pressures (a higher vacuum).

This staged approach is necessary because different pump technologies are optimized for different pressure ranges.

Vacuum Valves: Controlling the Flow

Valves are the gatekeepers of the vacuum system. They are not simple on/off switches but are crucial for orchestrating the entire process.

Their functions include isolating the main chamber from the pumps, controlling which pump is active, and enabling the introduction of specific process gases (like argon or nitrogen) for cooling or creating a specific inert atmosphere.

Vacuum Gauges: Measuring the Environment

You cannot control what you cannot measure. Vacuum gauges are the sensory organs of the system, providing a continuous, real-time measurement of the pressure inside the furnace chamber.

Like pumps, different gauges are used for different pressure ranges. A system might use one type of gauge to measure the initial "rough vacuum" and a more sensitive gauge to monitor the final "high vacuum" level, ensuring process specifications are met precisely.

Understanding the Trade-offs

The complexity of a vacuum system is directly tied to its intended application, which creates a clear trade-off between performance and cost.

System Capability vs. Cost

A furnace designed for simple degassing might only need a single, robust mechanical pump. This system is relatively simple and cost-effective.

However, a furnace built for brazing aerospace alloys or sintering advanced ceramics requires a high or ultra-high vacuum. This necessitates a more complex and expensive multi-stage system with sophisticated pumps, valves, and controls.

Maintenance and Operational Complexity

More advanced systems, particularly those with diffusion or turbomolecular pumps, require more stringent maintenance schedules and operational expertise. Leaks that are negligible in a rough vacuum system can be catastrophic for a high-vacuum process.

Making the Right Choice for Your Process

The ideal vacuum system configuration is dictated entirely by the material and the process requirements.

- If your primary focus is basic annealing or degassing: A simpler system with a mechanical roughing pump is often sufficient and cost-effective.

- If your primary focus is brazing, sintering, or heat-treating reactive metals: A multi-stage system with both roughing and high-vacuum pumps is essential to prevent oxidation and ensure process purity.

- If your primary focus is specialized research or semiconductor applications: An ultra-high vacuum (UHV) system with even more advanced pumps and all-metal seals is required to achieve the necessary level of cleanliness.

Ultimately, understanding these components allows you to see the vacuum system as the enabling technology that unlocks the full potential of your materials.

Summary Table:

| Component Type | Key Functions | Common Examples |

|---|---|---|

| Vacuum Pumps | Remove air and gases, create sub-atmospheric environment | Mechanical pumps, Diffusion pumps, Turbomolecular pumps |

| Vacuum Valves | Control gas flow, isolate chambers, enable process gas introduction | Isolation valves, Control valves |

| Vacuum Gauges | Measure pressure, ensure precise environmental control | Rough vacuum gauges, High-vacuum gauges |

Ready to enhance your lab's capabilities with a custom vacuum furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization ensures your unique experimental needs are met precisely. Contact us today to discuss how our high-temperature furnace solutions can drive your success in material processing!

Visual Guide

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the primary function of high-purity quartz sealed tubes? Master Sb-Te Alloy Synthesis with Precision Isolation

- What industrial and research applications are tube furnaces used for? Unlock Precise Thermal Processing Solutions

- What is the working principle of a vacuum tube furnace? Master Precise High-Temperature Processing

- How to clean a tube furnace? A Step-by-Step Guide to Safe and Effective Maintenance

- What is the primary function of a vacuum-sealed quartz tube in MnBi2Te4 growth? Ensure High-Purity Crystal Synthesis