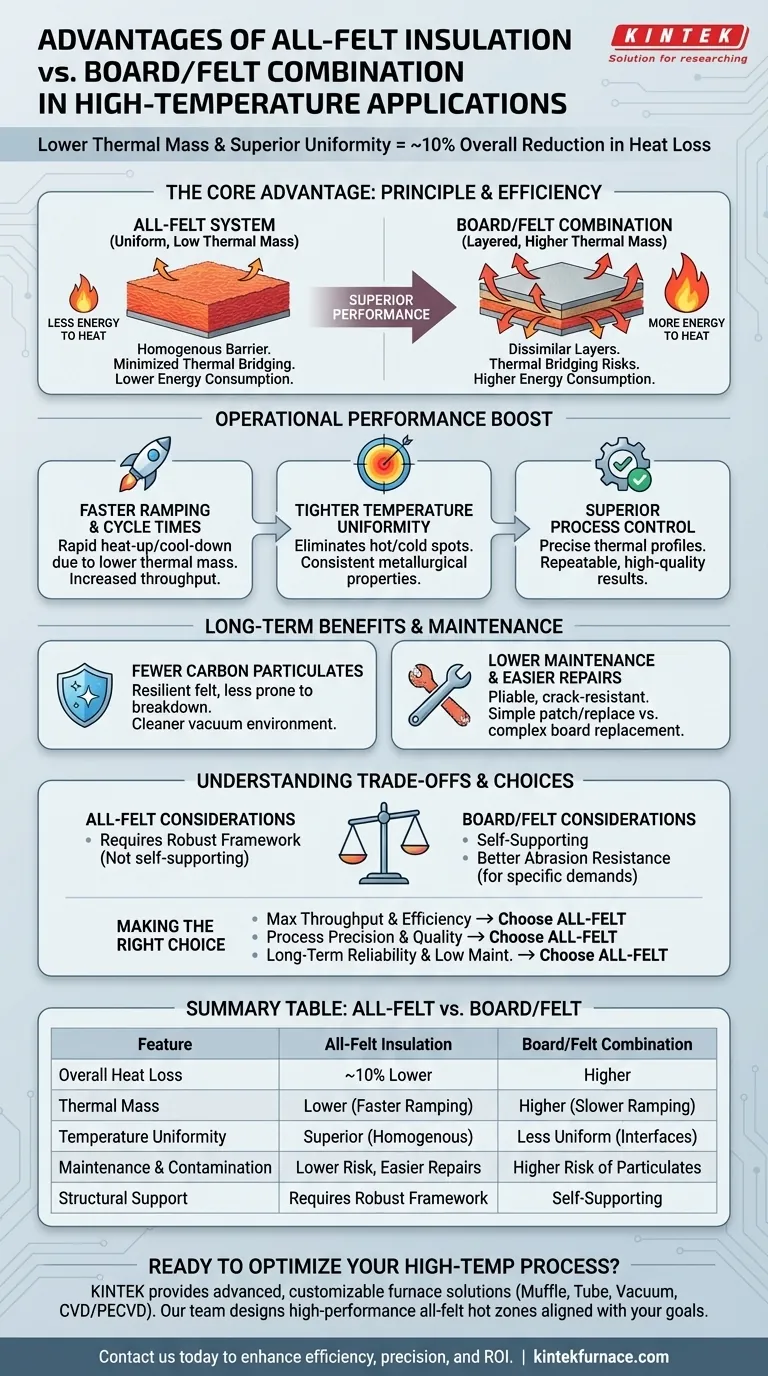

In high-temperature applications, an all-felt insulation system offers significant performance advantages over a traditional combination of rigid board and felt. It delivers a superior thermal barrier, resulting in approximately a 10% overall reduction in heat loss. This improved efficiency translates directly into lower energy consumption, faster equipment cycle times, and more precise process control.

The core advantage of all-felt insulation stems from its lower thermal mass and superior uniformity. This single characteristic creates a cascade of benefits, enhancing everything from energy efficiency and operational speed to process repeatability and long-term maintenance costs.

The Principle: Thermal Mass and Efficiency

The fundamental differences between all-felt and board/felt combinations begin with their physical properties. Understanding this is key to appreciating the operational impact.

Lower Heat Loss

An all-felt hot zone provides a more homogenous insulating barrier. This uniformity minimizes thermal bridging—direct pathways for heat to escape—which are more common in layered systems of dissimilar materials like board and felt. The result is a more effective containment of thermal energy and a direct reduction in overall heat loss.

Reduced Energy Consumption

Insulation doesn't just prevent heat from escaping; it also absorbs heat itself. Felt has a lower thermal mass than rigid board, meaning it requires less energy to reach the target temperature. This, combined with lower overall heat loss, means your system consumes significantly less energy during every operational cycle.

How All-Felt Enhances Operational Performance

The thermal efficiency of all-felt directly translates into measurable improvements in speed, precision, and product quality.

Faster Ramping and Cycle Times

Because all-felt has a lower thermal mass, it heats up and cools down much faster than denser board materials. This allows for faster temperature ramping, dramatically reducing the total cycle time for processes like vacuum heat treating or brazing. For facilities focused on throughput, this is a critical advantage.

Tighter Temperature Uniformity

A hot zone constructed entirely of felt is structurally and thermally homogenous. This eliminates the hot and cold spots that can develop at the interfaces between board and felt layers. The result is exceptional temperature uniformity across the entire work area, which is vital for achieving consistent metallurgical properties and part quality.

Superior Process Control

The combination of faster thermal response and excellent temperature uniformity gives operators tighter, more repeatable control over the entire process. Thermal profiles can be executed with greater precision, ensuring that parts consistently meet stringent specifications with every run.

Understanding the Long-Term Benefits

Beyond a single cycle, the choice of insulation material has a lasting impact on maintenance, system cleanliness, and overall reliability.

Fewer Carbon Particulates

Rigid carbon board can become brittle over time and is more susceptible to damage from mechanical shock or vibration. This degradation releases carbon particulates, which can contaminate the vacuum environment and the surface of the products being processed. Felt is more resilient and less prone to this type of breakdown.

Lower Maintenance and Easier Repairs

When a section of rigid board cracks or fails, it often requires a complex and time-consuming replacement. Felt, being pliable, is far more resistant to cracking. If damage does occur, a section of felt can often be patched or replaced with much greater ease, significantly reducing downtime and maintenance costs.

Understanding the Trade-offs

While all-felt offers compelling advantages, no engineering choice is without trade-offs. It is crucial to consider the complete picture.

Structural Considerations

Rigid board is, by its nature, self-supporting. An all-felt system is not. It requires a more complex and robust framework of retainers and mounting hardware to hold its shape and position. This can influence the initial design and construction of the hot zone.

Application-Specific Demands

In certain processes where the insulation face may be subject to direct mechanical contact or high-velocity gas flows, a rigid board hot face might be specified for its superior durability against abrasion. However, this is often addressed by using a combination system where the innermost layer is a durable board and the outer layers are efficient felt.

Making the Right Choice for Your Goal

Your decision should be guided by your primary operational and business objectives.

- If your primary focus is maximum throughput and energy efficiency: Choose an all-felt system to leverage its fast cycle times and lower energy consumption.

- If your primary focus is process precision and part quality: An all-felt system is the superior choice for its outstanding temperature uniformity and low risk of particulate contamination.

- If your primary focus is long-term reliability and low maintenance: The durability and easy repairability of all-felt will reduce downtime and operational costs over the life of the equipment.

Ultimately, selecting the right insulation is a strategic decision that aligns the thermal performance of your equipment with your long-term operational goals.

Summary Table:

| Feature | All-Felt Insulation | Board/Felt Combination |

|---|---|---|

| Overall Heat Loss | ~10% Lower | Higher |

| Thermal Mass | Lower (Faster Ramping) | Higher (Slower Ramping) |

| Temperature Uniformity | Superior (Homogenous) | Less Uniform (Interfaces) |

| Maintenance & Contamination | Lower Risk, Easier Repairs | Higher Risk of Particulates |

| Structural Support | Requires Robust Framework | Self-Supporting |

Ready to Optimize Your High-Temperature Process?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Whether your goal is maximum throughput, ultimate process precision, or long-term reliability, our team can design an insulation system—including high-performance all-felt hot zones—that aligns with your operational goals.

Contact us today to discuss how we can enhance your equipment's efficiency, precision, and ROI.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- Can a muffle furnace be used for pyrolysis? Unlock Precise Thermal Decomposition