In high-temperature vacuum processing, graphite is the material of choice for a wide range of critical internal components. Its primary applications are structural: creating the fixtures, racks, trays, and support systems used to hold parts during heat treating, brazing, and sintering. Graphite's unique properties ensure that components, especially those for aerospace and medical applications, maintain their precise shape and purity under extreme conditions.

Graphite is not merely a convenient material for vacuum furnaces; it is an enabling technology. Its unparalleled combination of high-temperature strength, thermal stability, and chemical inertness is what makes the precise, contamination-free processing of advanced materials possible.

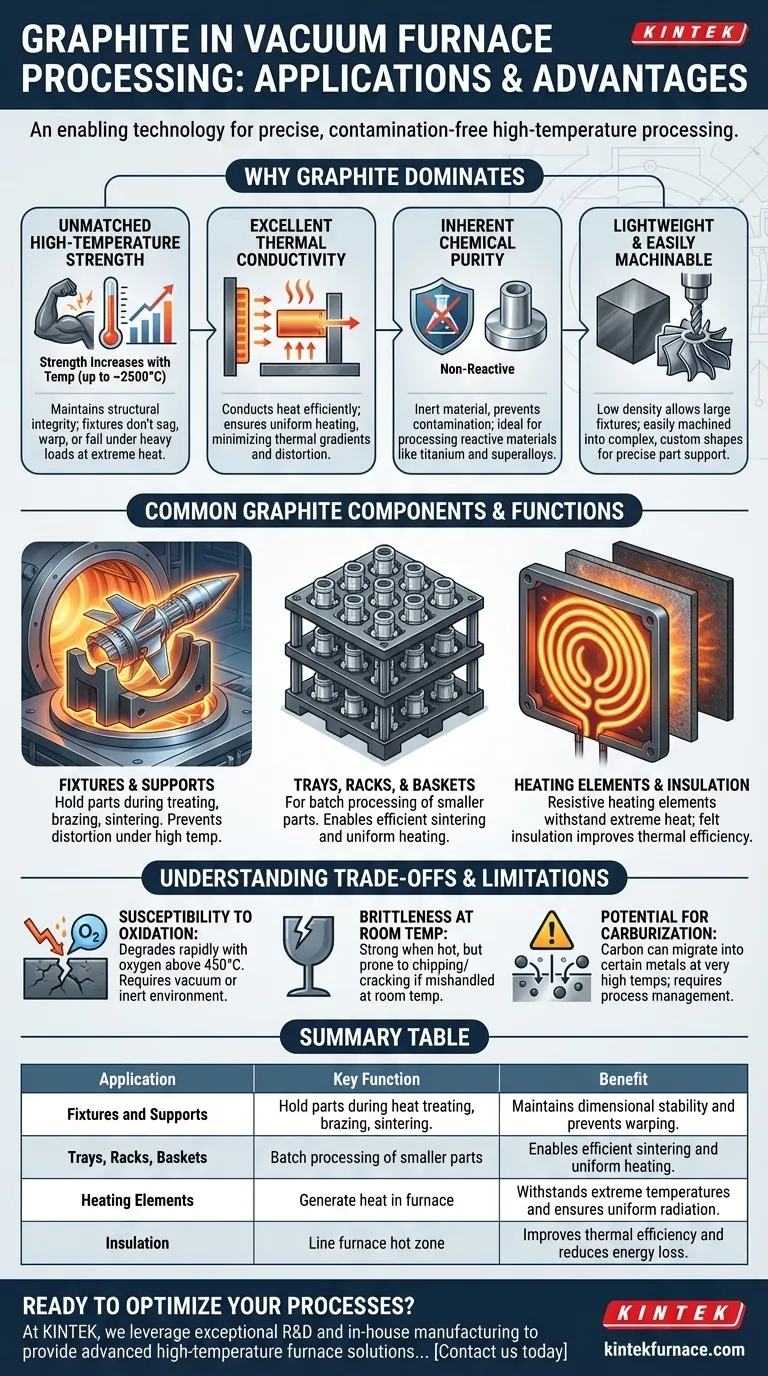

Why Graphite Dominates in Vacuum Furnaces

The use of graphite is a solution to the fundamental challenges of high-temperature metallurgy: maintaining dimensional stability, ensuring uniform heating, and preventing chemical contamination. Several core properties make it uniquely suited for this environment.

Unmatched High-Temperature Strength

Unlike metals that soften and lose strength as they are heated, graphite's structural integrity actually increases with temperature, peaking at around 2500°C.

This means that fixtures made from graphite will not sag, warp, or fail when holding heavy loads during a high-temperature heat treatment or brazing cycle.

Excellent Thermal Conductivity

Graphite conducts heat exceptionally well. This property ensures that heat is transferred uniformly from the furnace's heating elements through the fixtures and into the workpiece.

This uniformity minimizes thermal gradients across the part, which is critical for preventing internal stresses and distortion during both heating and cooling phases.

Inherent Chemical Purity

Graphite is a remarkably inert material that does not react with most metals, alloys, or ceramics, even at extreme temperatures.

This is essential when processing highly reactive materials like titanium or certain superalloys. Using graphite fixtures prevents contaminants from leaching into the workpiece, ensuring the final product meets stringent metallurgical standards.

Lightweight and Easily Machinable

Despite its strength, graphite has a low density, making large fixtures and support structures relatively easy to handle.

Furthermore, it can be readily machined into highly complex and intricate shapes. This allows for the creation of custom fixtures that provide precise support to complex components, such as aerospace turbine blades, minimizing warpage.

Common Graphite Components and Their Functions

The properties of graphite translate directly into the physical components used inside vacuum furnaces every day.

Fixtures and Supports

These are custom-designed structures for holding specific parts. For example, intricate graphite fixtures are used to support titanium aerospace components or large steel parts, ensuring they do not distort under their own weight at high temperatures.

Trays, Racks, and Baskets

For processing large batches of smaller parts, graphite is formed into trays, racks, and modular shelving systems. These are common in sintering applications for cemented carbides, magnets, and other powder metallurgy products.

Heating Elements and Insulation

In many furnace designs, graphite itself serves as the resistive heating element. Its ability to withstand extreme temperatures while radiating heat efficiently makes it ideal for this purpose.

Graphite is also processed into a soft felt, which is used as a high-performance thermal insulation lining for the furnace's hot zone, further improving thermal efficiency.

Understanding the Trade-offs and Limitations

While graphite is an exceptional material, it is not without limitations. Acknowledging these is key to successful process design.

Susceptibility to Oxidation

Graphite's primary weakness is its reaction with oxygen at elevated temperatures (typically above 450°C), which causes it to rapidly degrade. This is precisely why it is so effective in a vacuum or inert gas environment, where oxygen is eliminated.

Brittleness at Room Temperature

While strong when hot, graphite can be brittle and prone to chipping or cracking if mishandled at room temperature. Components must be loaded and unloaded with care to avoid mechanical shock.

Potential for Carburization

In direct contact with certain metals, such as some types of steel, carbon can migrate from the graphite into the part's surface at very high temperatures. This process, called carburization, can alter the properties of the workpiece and must be accounted for in the process design, sometimes by using ceramic barrier coatings.

Making the Right Choice for Your Application

The specific grade and design of your graphite components should be dictated by your process goals.

- If your primary focus is processing reactive metals (e.g., titanium): High-purity, low-ash graphite is essential to prevent contamination and ensure the material's metallurgical integrity.

- If your primary focus is dimensional stability of complex parts: Intricately machined, custom graphite fixtures are critical to properly support components and minimize warpage during the thermal cycle.

- If your primary focus is batch processing of smaller components: Modular graphite trays, racks, and carrier systems offer the best combination of thermal performance and loading efficiency for sintering or brazing.

Ultimately, graphite's properties make it a foundational material that enables the advanced manufacturing of today's most critical components.

Summary Table:

| Application | Key Function | Benefit |

|---|---|---|

| Fixtures and Supports | Hold parts during heat treating, brazing, sintering | Maintains dimensional stability and prevents warping |

| Trays, Racks, Baskets | Batch processing of smaller parts | Enables efficient sintering and uniform heating |

| Heating Elements | Generate heat in furnace | Withstands extreme temperatures and ensures uniform radiation |

| Insulation | Line furnace hot zone | Improves thermal efficiency and reduces energy loss |

Ready to optimize your high-temperature processes with custom graphite solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, whether you're in aerospace, medical, or other advanced material fields. Contact us today to discuss how our expertise can enhance your lab's efficiency and results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control