At its core, a vacuum brazing furnace prevents oxidation by physically removing the reactive atmosphere—primarily oxygen—from the heating chamber. Before the heating process begins, a system of powerful vacuum pumps evacuates the air from the sealed chamber. By creating a high-vacuum environment, there are simply not enough oxygen molecules remaining to react with the hot metal surfaces, ensuring a chemically clean process from start to finish.

The fundamental principle of vacuum brazing isn't about adding a protective element, but about subtracting the reactant. A vacuum furnace creates an environment so devoid of oxygen that oxidation, a chemical reaction requiring oxygen, cannot meaningfully occur, resulting in exceptionally clean and strong brazed joints.

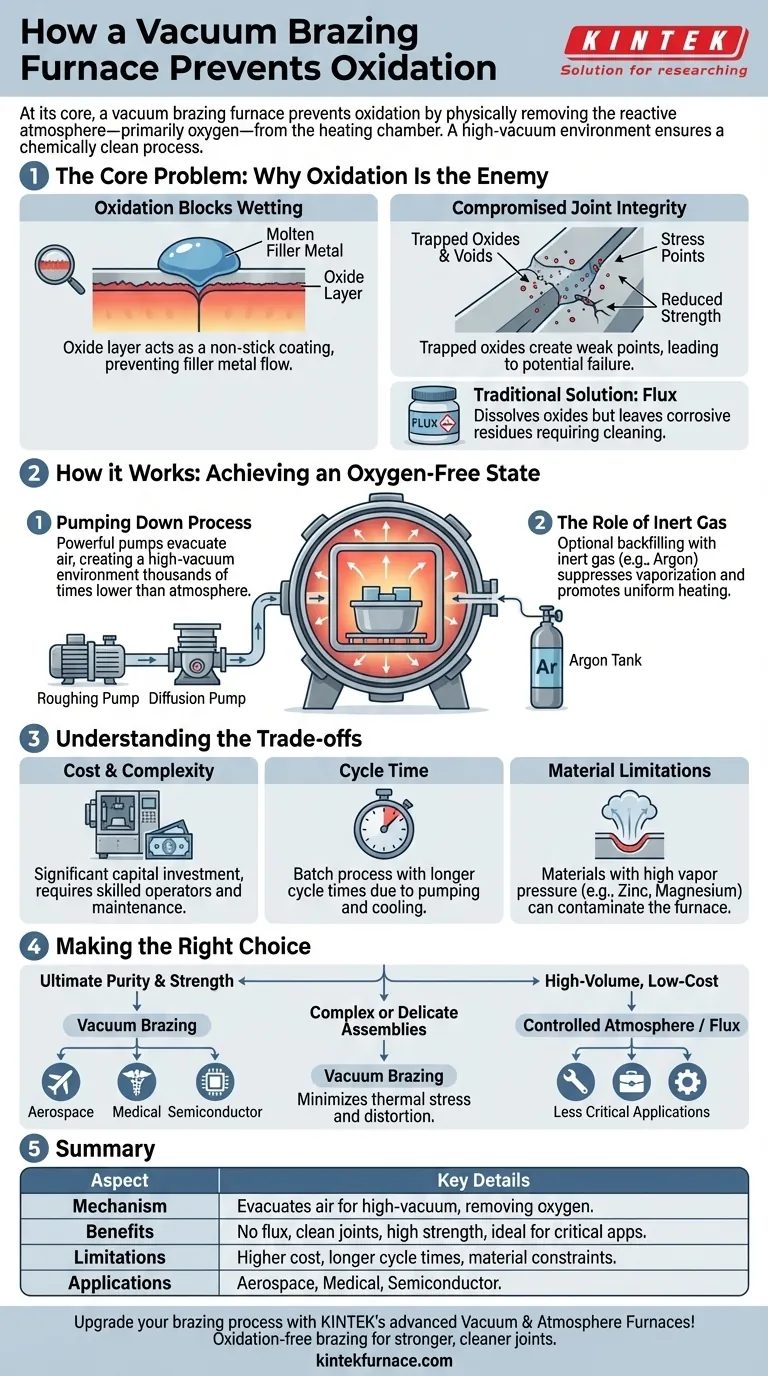

The Core Problem: Why Oxidation Is the Enemy of Brazing

To understand the value of a vacuum, you must first understand why oxidation is so detrimental to the brazing process.

Oxidation Blocks Wetting and Flow

When metals are heated, they readily react with oxygen to form a thin, hard layer of metal oxide on their surface. This oxide layer acts like a non-stick coating.

The success of brazing depends on the molten filler metal "wetting" the base metals and being pulled into the joint by capillary action. An oxide layer completely prevents this, causing the filler metal to bead up and fail to create a bond.

Compromised Joint Integrity

Even if a joint is partially formed, any oxides that become trapped within the brazement create voids and impurities. These act as stress points, dramatically reducing the strength, ductility, and fatigue life of the final component.

Traditional Solutions and Their Limits

The traditional method for combating oxidation is to use a chemical flux. Flux melts and dissolves oxides, allowing the filler metal to flow.

However, fluxes can leave behind corrosive residues that must be thoroughly cleaned in a post-brazing operation. Incomplete cleaning can lead to long-term corrosion and failure of the part. Vacuum brazing eliminates the need for flux and the associated cleaning step entirely.

How a Vacuum Furnace Achieves an Oxygen-Free State

The process of creating this pristine environment is a multi-stage engineering feat.

The Pumping Down Process

A vacuum furnace is a sealed vessel connected to a series of vacuum pumps. The process begins with a "roughing pump" that removes the vast majority of the air.

Following this, a high-vacuum pump, such as a diffusion or turbomolecular pump, takes over. It continues to remove molecules from the chamber, reducing the internal pressure to a level thousands of times lower than the atmosphere.

The Role of Inert Gas

In some advanced cycles, after the initial high vacuum is achieved, the furnace may be backfilled with a small, controlled amount of an inert gas like Argon.

This "partial pressure" of inert gas is useful for two reasons: it helps suppress the vaporization of volatile elements in the base metal (like zinc) and promotes more uniform heating of the parts.

Understanding the Trade-offs

While powerful, vacuum brazing is not the universal solution for all applications. Objectivity requires acknowledging its limitations.

Cost and Complexity

Vacuum furnaces represent a significant capital investment. They are complex machines that require skilled operators and rigorous maintenance schedules to perform reliably.

Cycle Time Considerations

Because of the need to pump down the chamber, heat the workload, and cool it under controlled conditions, vacuum brazing is a batch process. Cycle times can be significantly longer than for continuous methods like belt furnace brazing.

Material Limitations

Materials with high vapor pressure, such as zinc, magnesium, or cadmium, can be problematic. Under a high vacuum, these elements can "boil off" from the base metal, contaminating the furnace and depleting the alloy.

Making the Right Choice for Your Application

Selecting the right brazing method depends entirely on your technical requirements and production goals.

- If your primary focus is ultimate joint purity and strength: Vacuum brazing is the superior choice, essential for mission-critical parts in the aerospace, medical, and semiconductor industries.

- If your primary focus is high-volume, low-cost production: A controlled atmosphere furnace (using a gas like hydrogen) or traditional flux brazing may be more economical for less critical applications.

- If your primary focus is joining complex or delicate assemblies: The uniform heating and cooling of a vacuum furnace minimizes thermal stress and distortion, making it ideal.

By understanding that vacuum brazing works by removing the conditions required for oxidation, you can confidently specify it for applications where joint integrity is paramount.

Summary Table:

| Aspect | Key Details |

|---|---|

| Mechanism | Evacuates air to create a high-vacuum environment, removing oxygen molecules to prevent oxidation. |

| Benefits | No flux needed, clean joints, high strength, ideal for critical applications like aerospace and medical devices. |

| Limitations | Higher cost, longer cycle times, not suitable for materials with high vapor pressure (e.g., zinc). |

| Applications | Aerospace, medical, semiconductor industries where joint purity and integrity are essential. |

Upgrade your brazing process with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Vacuum & Atmosphere Furnaces and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs, delivering oxidation-free brazing for stronger, cleaner joints. Contact us today to discuss how we can enhance your lab's efficiency and results!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

People Also Ask

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?