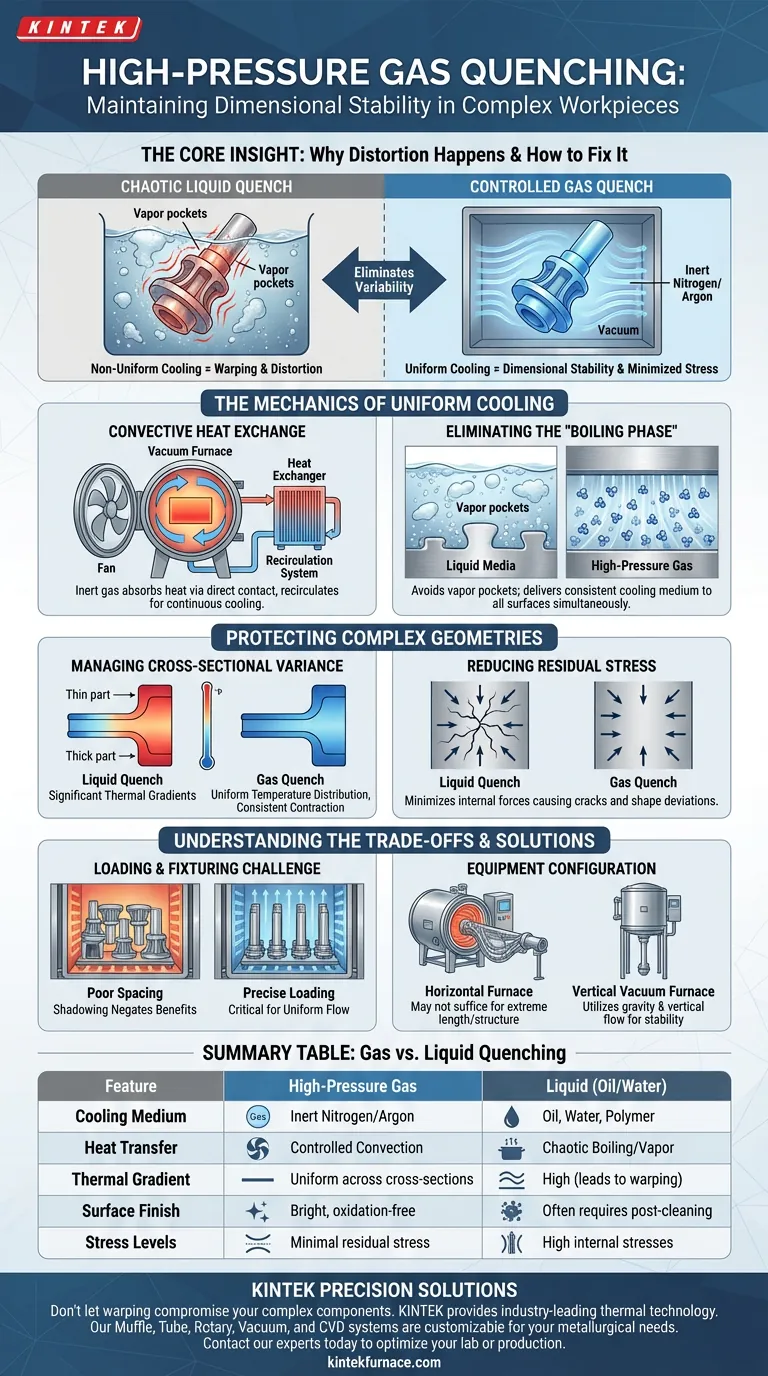

High-pressure gas quenching preserves dimensional stability by utilizing controlled convective heat transfer to ensure uniform cooling rates across the entire workpiece. By replacing the chaotic thermal shock associated with liquid quenchants, this process minimizes the internal stresses that lead to warping and distortion in complex geometries.

The Core Insight: The primary driver of distortion during heat treatment is non-uniform cooling, which creates competing forces within the material. High-pressure gas quenching eliminates this variability, ensuring that thin and thick cross-sections cool at a similar rate, thereby neutralizing the residual stresses that cause cracks and shape deviations.

The Mechanics of Uniform Cooling

Convective Heat Exchange

Unlike traditional methods that rely on liquid immersion, gas quenching systems typically utilize nitrogen to extract heat.

The inert gas circulates over the hot load, absorbing thermal energy through direct contact. This heated gas is then routed out of the chamber, cooled via heat exchangers, and recirculated back into the furnace to continue the cycle.

Eliminating the "Boiling Phase"

Liquid media, such as oil or water, often undergo phase changes (boiling) upon contact with hot metal.

This creates vapor pockets that insulate parts of the surface while other areas cool rapidly. High-pressure gas avoids this phenomenon entirely, delivering a consistent cooling medium to every surface of the workpiece simultaneously.

Protecting Complex Geometries

Managing Cross-Sectional Variance

Complex workpieces often feature varying thicknesses, where thin sections naturally cool faster than thick ones.

In a liquid quench, this discrepancy causes significant thermal gradients. High-pressure gas cooling achieves a uniform temperature distribution across these varying cross-sections, keeping the thermal contraction consistent throughout the part.

Reducing Residual Stress

Shape deviation is physically caused by residual stresses—internal forces that remain after the process is complete.

By ensuring uniformity during the critical cooling phase, gas quenching minimizes the generation of these stresses. This is the essential factor in preventing material cracking and maintaining strict dimensional tolerances.

Understanding the Trade-offs

The Challenge of Loading and Fixturing

While the gas process is superior for stability, the arrangement of the parts inside the furnace is critical.

References indicate that for large or particularly complex shapes, achieving uniform gas flow requires precise loading strategies. Poor spacing or "shadowing" (where one part blocks airflow to another) can negate the benefits of the gas quench.

Equipment Configuration

Standard horizontal furnaces may not suffice for all distinct geometries.

Parts with "increased structure" or extreme length often require vertical vacuum furnaces. These specialized configurations utilize gravity and vertical airflow to ensure stability and uniformity that horizontal loading cannot always guarantee.

Making the Right Choice for Your Goal

- If your primary focus is Dimensional Precision: Rely on high-pressure gas quenching to minimize residual stress and prevent the warping common with liquid quenchants.

- If your primary focus is Complex or Long Structures: Investigate vertical vacuum furnace configurations to ensure uniform load density and prevent gravity-induced distortion.

- If your primary focus is Surface Integrity: Utilize the vacuum environment to eliminate oxidation and decarburization, ensuring a clean surface without a metamorphic layer.

High-pressure gas quenching transforms the cooling process from a chaotic thermal shock into a controlled, predictable operation that safeguards the geometry of your most critical components.

Summary Table:

| Feature | High-Pressure Gas Quenching | Liquid Quenching (Oil/Water) |

|---|---|---|

| Cooling Medium | Inert Nitrogen/Argon | Oil, Water, or Polymer |

| Heat Transfer | Controlled Convection | Chaotic Boiling/Vapor Phase |

| Thermal Gradient | Uniform across cross-sections | High (leads to warping) |

| Surface Finish | Bright, oxidation-free | Often requires post-cleaning |

| Stress Levels | Minimal residual stress | High internal stresses |

Precision Heat Treatment Solutions for Your Toughest Geometries

Don't let warping and internal stresses compromise the integrity of your complex components. KINTEK provides industry-leading thermal technology backed by expert R&D and precision manufacturing. Our range of Muffle, Tube, Rotary, Vacuum, and CVD systems are all fully customizable to meet your unique metallurgical requirements.

Whether you are processing aerospace parts or intricate medical devices, KINTEK ensures your materials achieve the highest dimensional stability and surface quality. Contact our technical experts today to discover how our high-temp furnaces can optimize your lab or production workflow.

Visual Guide

References

- André Paulo Tschiptschin. PROCESSOS SOB VÁCUO USADOS PARA TRATAMENTOS TÉRMICOS E DE SUPERFÍCIE DE AÇOS E LIGAS ESPECIAIS. DOI: 10.17563/rbav.v43i1.1262

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What are some common industrial applications of vacuum furnaces? Unlock Purity and Performance in Your Processes

- What safety features are enhanced in vacuum furnaces? Discover Inherent Fire and Explosion Prevention

- Which industries commonly use vacuum arc furnaces and why? Unlock Ultra-Pure Metals for Aerospace, Medical, and Energy

- What physical conditions do laboratory thermal cycling systems provide for hydride reorientation in zirconium alloys?

- What are the disadvantages of graphite furnace? High Cost, Slow Speed, and Complexity

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- What are some industrial applications of vacuum furnaces? Unlock Superior Material Performance

- What technical advantages do vacuum high-temperature furnaces provide for sandwich panel brazing? Achieve Stronger Bonds