The defining safety enhancement of a vacuum furnace is the environment it creates. By removing atmospheric air, these furnaces fundamentally eliminate the conditions required for common industrial hazards like fires and explosions, while their automated nature significantly reduces the potential for human error.

Vacuum furnace safety is not based on adding complex safety systems to a dangerous process. Instead, it is rooted in the inherent physics of operating at negative pressure in an oxygen-free environment, which removes the root causes of fires and pressure-related explosions.

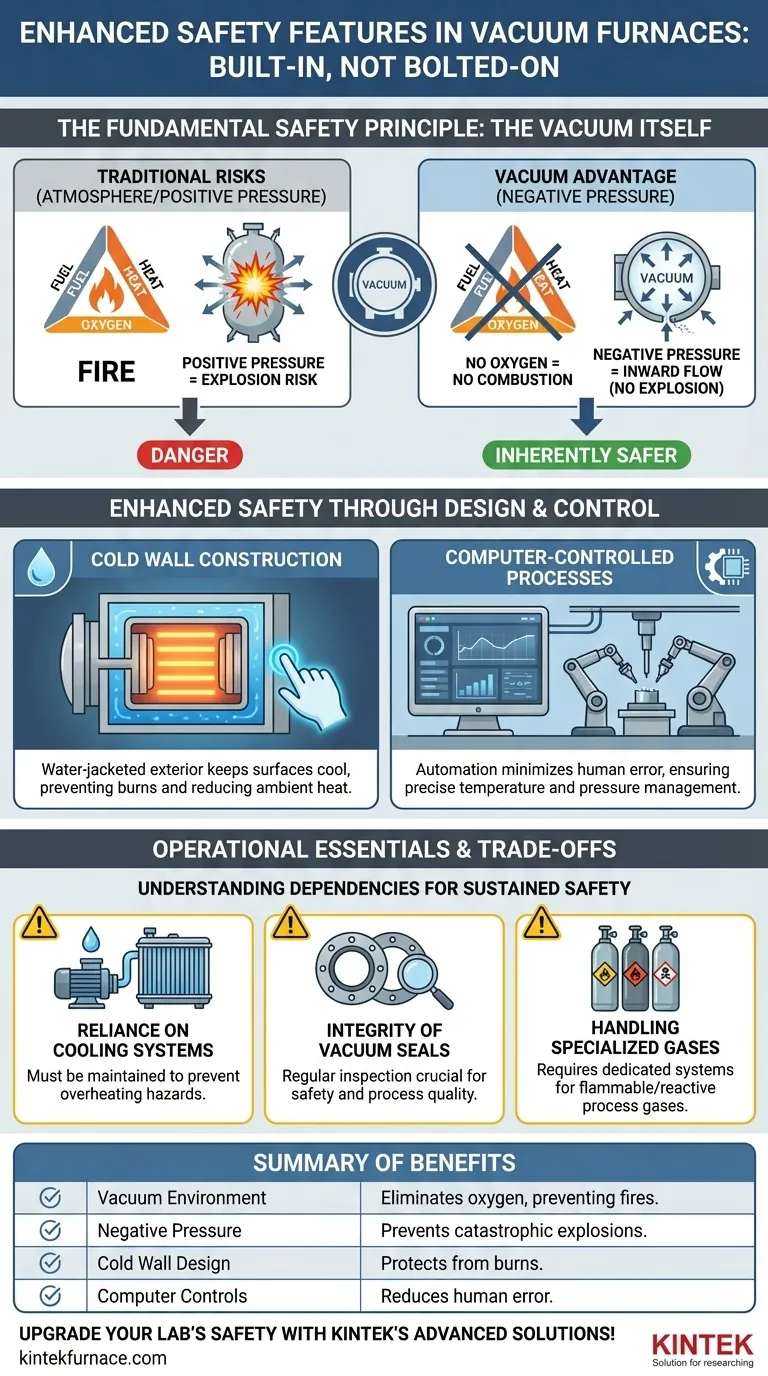

The Fundamental Safety Principle: The Vacuum Itself

The primary safety advantages of a vacuum furnace are not add-on features but are intrinsic to its core function. Operating in a vacuum creates an environment that is fundamentally safer than traditional atmosphere or pressure-based heating systems.

Eliminating the Risk of Fire

A fire requires three components: fuel, heat, and oxygen. A vacuum furnace works by removing virtually all of the oxygen from its chamber.

Without oxygen, combustion cannot occur. This drastically reduces the risk of fire from the oxidation of workpieces or other materials inside the furnace, a common concern in conventional heating processes.

Preventing Explosions with Negative Pressure

Standard boilers and many atmosphere furnaces operate at positive pressure, meaning the pressure inside is greater than the pressure outside. A failure in the vessel can lead to a violent explosion, releasing energy outwards.

Vacuum furnaces operate at negative pressure. If a leak occurs, the higher-pressure air from the outside flows into the chamber, not the other way around. This design principle eliminates the risk of catastrophic pressure-related explosions.

Enhanced Safety Through Design and Control

Beyond the vacuum itself, modern vacuum furnaces incorporate design and automation features that further improve operator and facility safety.

Cold Wall Construction

Most vacuum furnaces utilize a water-jacketed cold wall design. The heating elements and hot zone are contained within a chamber whose outer walls are actively cooled with water.

This keeps the exterior of the furnace at or near room temperature, protecting operators from burns and reducing the ambient heat load in the workspace.

Computer-Controlled Processes

Modern furnaces are integrated with sophisticated computer controls that manage every aspect of the heating and cooling cycle. This programmable control ensures precision and repeatability.

By automating the process, the potential for human error—a leading cause of industrial accidents—is significantly minimized. The system monitors and maintains precise temperatures and pressures, preventing dangerous deviations.

Understanding the Trade-offs

While inherently safe, the safety of a vacuum furnace system relies on proper design, operation, and maintenance. Understanding these dependencies is critical.

Reliance on Cooling Systems

The "cold wall" design is highly effective, but it is entirely dependent on the continuous and correct operation of its water cooling system. A failure in the water supply can lead to rapid overheating of the chamber walls, creating a significant hazard. Proper maintenance and monitoring of the cooling circuit are non-negotiable.

Integrity of Vacuum Seals

The safety benefit of negative pressure depends on maintaining the integrity of the furnace chamber. While a leak does not cause an explosion, it can compromise the process, ruin the workpiece, and potentially damage internal furnace components if air rushes in at high temperatures. Regular inspection of all seals and gaskets is crucial.

Handling of Specialized Process Gases

While many processes run in a pure vacuum, some require the introduction of specific gases for quenching or other reactions. If these gases are flammable (like hydrogen) or reactive, they introduce new safety considerations that must be managed with dedicated gas handling systems, sensors, and protocols.

Making the Right Choice for Your Operation

Choosing a furnace technology requires balancing safety, quality, and operational cost.

- If your primary focus is facility and operator safety: The inherent elimination of fire and explosion risks due to the oxygen-free, negative-pressure environment is the most compelling advantage.

- If your primary focus is process consistency and quality: The precise, computer-controlled environment not only enhances quality but also serves as a key safety feature by reducing human error.

- If your primary focus is working with highly reactive materials: A vacuum furnace provides the essential oxygen-free environment, but you must invest in the appropriate systems to safely manage any required process gases.

Ultimately, the safety of a vacuum furnace is designed into its core, making it a fundamentally secure choice for modern thermal processing.

Summary Table:

| Safety Feature | Key Benefit |

|---|---|

| Vacuum Environment | Eliminates oxygen, preventing fires and explosions |

| Negative Pressure | Prevents catastrophic pressure-related explosions |

| Cold Wall Design | Protects operators from burns with water-cooled walls |

| Computer Controls | Reduces human error through automated process management |

| Reliance on Cooling Systems | Requires maintenance to prevent overheating hazards |

| Vacuum Seal Integrity | Essential for maintaining safety and process quality |

| Specialized Gas Handling | Manages risks when using flammable or reactive gases |

Upgrade your lab's safety and efficiency with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs. Contact us today to learn how our vacuum furnaces can enhance your operational safety and performance!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity