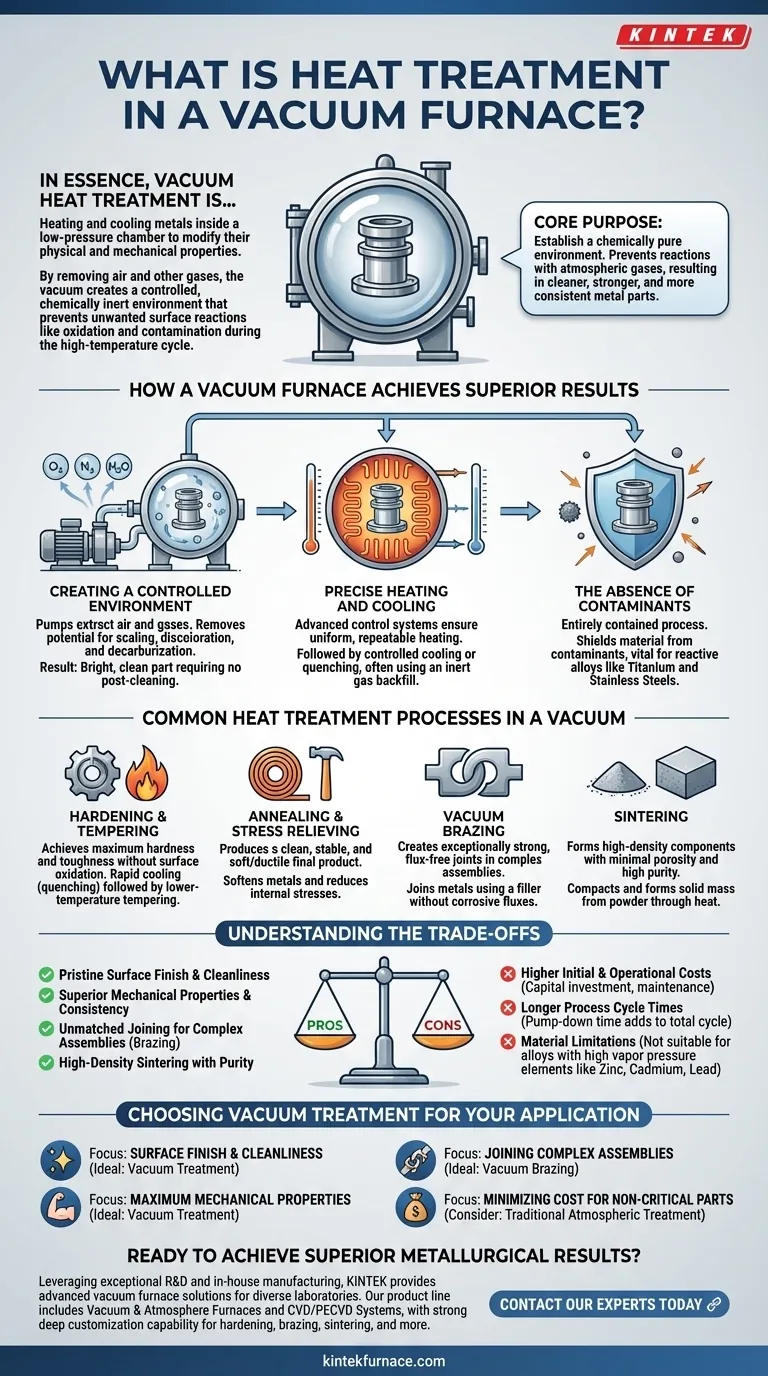

In essence, vacuum heat treatment is the process of heating and cooling metals inside a low-pressure chamber to modify their physical and mechanical properties. By removing air and other gases, the vacuum creates a controlled, chemically inert environment that prevents unwanted surface reactions like oxidation and contamination during the high-temperature cycle.

The core purpose of using a vacuum is not simply to create an empty space, but to establish a chemically pure environment. This prevents reactions with atmospheric gases, resulting in cleaner, stronger, and more consistent metal parts compared to traditional furnace methods.

How a Vacuum Furnace Achieves Superior Results

A vacuum furnace operates on a principle of control. By removing the unpredictable variable of atmospheric air, it allows for unparalleled precision in metallurgical processes.

Creating a Controlled Environment

The process begins by using powerful pumps to extract air from a sealed chamber. This removal of oxygen, nitrogen, and water vapor is critical, as these gases can react with hot metal surfaces, causing scaling, discoloration, and decarburization.

The result is a bright, clean part that often requires no subsequent cleaning or surface finishing.

Precise Heating and Cooling

Once the vacuum is established, internal heating elements raise the material's temperature. Advanced control systems ensure this heating is extremely uniform across the entire part and highly repeatable from one cycle to the next.

This precision is key to achieving specific, targeted metallurgical structures and properties consistently. Following the heating cycle, controlled cooling or quenching can be performed, often using an inert gas backfill to extract heat rapidly.

The Absence of Contaminants

Because the process is entirely contained, the material is shielded from any contaminants present in a typical furnace atmosphere. This is vital for reactive and high-performance alloys like titanium, superalloys, and certain stainless steels.

Common Heat Treatment Processes in a Vacuum

The versatility of a vacuum furnace allows it to perform a wide array of thermal processes, often with better results than their atmospheric counterparts.

Hardening and Tempering

Hardening involves heating a steel to a critical temperature and then cooling it rapidly (quenching) to create a very hard, brittle structure. Tempering is a subsequent lower-temperature treatment that reduces this brittleness and imparts toughness. Vacuum processing ensures these properties are developed without detrimental surface oxidation.

Annealing and Stress Relieving

Annealing is a process used to soften metals, increase their ductility, and refine their grain structure. Stress relieving is a similar, lower-temperature process that reduces internal stresses caused by manufacturing operations like welding or machining. A vacuum ensures these processes result in a clean, stable final product.

Vacuum Brazing

Vacuum brazing is a premier method for joining metals. It uses a filler metal to create a strong metallurgical bond between components. Performing this in a vacuum eliminates the need for corrosive chemical fluxes, producing exceptionally clean and strong joints, especially in complex or high-value assemblies.

Sintering

Sintering is the process of compacting and forming a solid mass of material from powder through heat without melting it to the point of liquefaction. Vacuum sintering is used to produce high-density components with minimal porosity and excellent material purity.

Understanding the Trade-offs

While powerful, vacuum heat treatment is not a universal solution. Understanding its limitations is crucial for making an informed decision.

Higher Initial and Operational Costs

Vacuum furnaces represent a significant capital investment compared to conventional atmospheric furnaces. Their complexity, including vacuum pumps and sophisticated control systems, also leads to higher maintenance and operational costs.

Longer Process Cycle Times

The time required to pump the chamber down to the target vacuum level adds to the overall cycle time. For high-volume, low-margin parts, this can be a significant economic disadvantage compared to faster atmospheric processes.

Material and Process Limitations

Certain materials are not suitable for vacuum processing. For example, alloys containing elements with a high vapor pressure (like zinc, cadmium, or lead) can outgas and contaminate the furnace and the parts being processed.

Choosing Vacuum Treatment for Your Application

The decision to use a vacuum furnace should be driven by the final requirements of your component.

- If your primary focus is surface finish and cleanliness: Vacuum treatment is ideal, as it prevents oxidation and often eliminates the need for post-process cleaning.

- If your primary focus is achieving maximum mechanical properties: The precise control and pure environment of a vacuum furnace deliver highly consistent and superior metallurgical results.

- If your primary focus is joining complex assemblies: Vacuum brazing offers an unmatched solution for creating strong, flux-free joints in intricate parts.

- If your primary focus is minimizing cost for non-critical parts: Traditional atmospheric heat treatment may be a more economical choice if a pristine surface is not required.

By understanding its principles, you can leverage vacuum heat treatment to achieve a level of quality and performance that is simply unattainable in a conventional atmosphere.

Summary Table:

| Process | Key Benefit in Vacuum |

|---|---|

| Hardening & Tempering | Achieves maximum hardness and toughness without surface oxidation. |

| Annealing & Stress Relieving | Produces a clean, stable, and soft/ductile final product. |

| Vacuum Brazing | Creates exceptionally strong, flux-free joints in complex assemblies. |

| Sintering | Forms high-density components with minimal porosity and high purity. |

Ready to achieve superior metallurgical results with pristine surface finishes?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced vacuum furnace solutions. Our product line, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements for hardening, brazing, sintering, and more.

Contact our experts today to discuss how a KINTEK vacuum furnace can enhance your process and deliver unmatched quality for your high-performance alloys and critical components.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing