At their core, vacuum furnaces are used for a wide range of industrial processes where material purity and structural integrity are paramount. Common applications include heat treating to strengthen metals like steel, vacuum brazing to join complex components for aerospace, sintering powdered metals into solid parts for the tool industry, and growing ultra-pure crystals for semiconductors.

The fundamental value of a vacuum furnace is its ability to create a controlled, contamination-free environment. By removing air and other gases, it prevents unwanted chemical reactions like oxidation, enabling material properties and manufacturing outcomes that are impossible to achieve in a standard atmosphere.

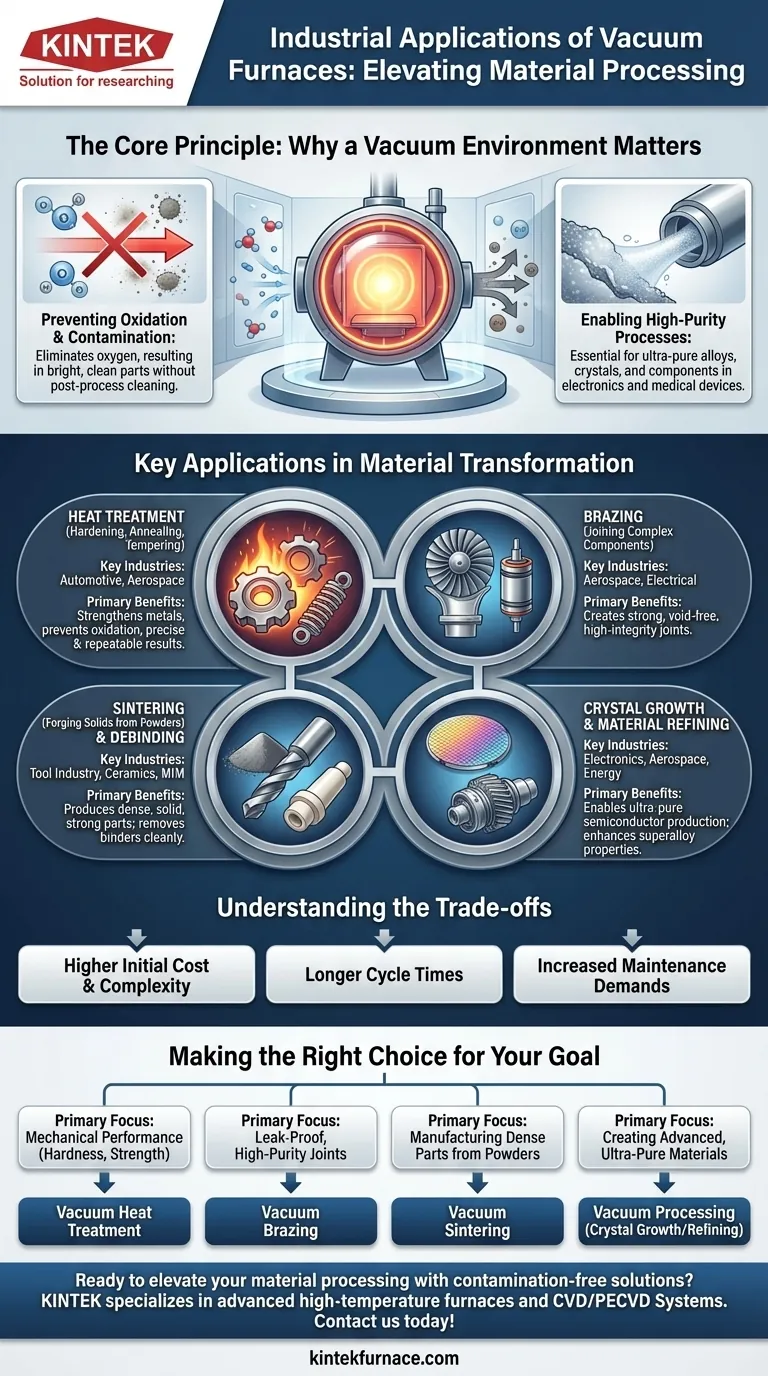

The Core Principle: Why a Vacuum Environment Matters

A vacuum furnace's primary function is to remove the atmosphere from its heating chamber. This simple act has profound implications for materials processing.

Preventing Oxidation and Contamination

The most significant benefit is the elimination of oxygen. At high temperatures, most metals react with oxygen, forming a brittle oxide layer that compromises strength, surface finish, and the ability to join parts.

A vacuum environment prevents this oxidation, resulting in bright, clean parts that require no post-process cleaning. It also prevents reactions with other atmospheric gases like nitrogen.

Enabling High-Purity Processes

For industries like electronics and medical devices, even microscopic impurities can cause catastrophic failure. A vacuum ensures the material being processed is not contaminated by atmospheric gases, allowing for the creation of ultra-pure alloys, crystals, and components.

Key Applications in Material Transformation

The controlled environment of a vacuum furnace unlocks a variety of powerful manufacturing and treatment processes across numerous industries.

Heat Treatment: Hardening and Strengthening Metals

This is one of the most common uses. Processes like annealing (softening), tempering (reducing brittleness), and hardening (quenching) are performed in a vacuum to achieve precise, repeatable results without surface degradation.

This is critical for high-performance steel alloys used in the automotive and aerospace industries for gears, bearings, and structural components.

Brazing: Creating High-Integrity Joints

Vacuum brazing is a process for joining metal parts using a filler metal. Performing this in a vacuum is superior because it ensures the surfaces to be joined are perfectly clean, free of oxides.

This allows the brazing alloy to flow evenly and create a strong, void-free joint. It is essential for manufacturing complex assemblies like vacuum interrupters for the electrical industry and turbine components for aerospace.

Sintering: Forging Solids from Powders

Sintering is the process of taking a compacted powder—metal or ceramic—and heating it to bond the particles into a solid object.

Vacuum sintering is used to produce tungsten carbide tools, dense ceramic parts, and components from metal injection molding (MIM). The vacuum prevents gas entrapment, leading to a denser and stronger final product.

Debinding: A Step in Advanced Manufacturing

Before sintering a part made via Metal Injection Molding (MIM), the "binder" material that holds the metal powder in its initial shape must be removed. Vacuum debinding is a clean and efficient way to thermally evaporate this binder without damaging the part.

High-Purity and Specialty Applications

Beyond common metal treatments, vacuum furnaces are essential for creating the building blocks of modern technology.

Crystal Growth: The Foundation of Electronics

The manufacturing of semiconductors and optical crystals requires an environment of extreme purity. A vacuum furnace provides the pristine conditions necessary to grow large, single crystals without defects, which is fundamental to the electronics industry.

Material Refining: Creating Superalloys

Specialty metals like titanium and nickel-based superalloys, which are the backbone of the aerospace and energy sectors, are refined and processed in a vacuum. This removes dissolved gases like hydrogen and oxygen, dramatically improving the material's mechanical properties and fatigue resistance.

Understanding the Trade-offs

While powerful, vacuum furnaces are not a universal solution. Understanding their limitations is key to making an informed decision.

Higher Initial Cost and Complexity

Vacuum furnaces are significantly more expensive to purchase and install than their atmospheric counterparts due to the need for vacuum pumps, complex seals, and sophisticated control systems.

Longer Cycle Times

The process of pumping the chamber down to a vacuum and, in many cases, backfilling it with an inert gas for cooling, adds time to each cycle. This can reduce throughput compared to continuous atmospheric furnaces.

Increased Maintenance Demands

The high-vacuum systems, seals, and internal components like heating elements require specialized and consistent maintenance to ensure performance and prevent costly leaks or failures.

Making the Right Choice for Your Goal

The decision to use a vacuum furnace is driven entirely by the required quality and performance of the final product.

- If your primary focus is mechanical performance: Vacuum heat treatment is the best choice for achieving superior hardness, strength, and fatigue life in critical metal components.

- If your primary focus is creating leak-proof, high-purity joints: Vacuum brazing is essential for building complex assemblies in the aerospace, medical, and electronics industries.

- If your primary focus is manufacturing dense parts from powders: Vacuum sintering is the standard for producing high-quality carbide tools and advanced ceramic components.

- If your primary focus is creating advanced, ultra-pure materials: Vacuum processing is non-negotiable for producing semiconductor crystals and refining superalloys for extreme environments.

Ultimately, a vacuum furnace is the tool of choice when the material's final properties must be perfect and uncontaminated by the outside world.

Summary Table:

| Application | Key Industries | Primary Benefits |

|---|---|---|

| Heat Treatment | Automotive, Aerospace | Strengthens metals, prevents oxidation |

| Brazing | Aerospace, Electrical | Creates strong, clean joints |

| Sintering | Tool Industry, Ceramics | Produces dense, solid parts from powders |

| Crystal Growth | Electronics | Enables ultra-pure semiconductor production |

| Material Refining | Aerospace, Energy | Removes impurities, enhances alloy properties |

Ready to elevate your material processing with contamination-free solutions? KINTEK specializes in advanced high-temperature furnaces, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, tailored to your unique needs. Our deep customization capabilities ensure precise performance for industries like aerospace, automotive, and electronics. Contact us today to discuss how we can enhance your efficiency and product quality!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How does a high-precision vacuum aging furnace control precipitation in superalloys? Engineering Gamma Prime Phases

- What are the advantages of vacuum carburizing over conventional atmosphere-carburizing methods? Boost Quality and Efficiency in Case Hardening

- How does the vacuum environment benefit material processing? Achieve Superior Purity and Control

- How does a high-temperature austenitization furnace ensure structural transformation? Mastering Fe-5%Mn-C Quenching

- How does a high-vacuum pump system facilitate the synthesis of high-quality calcium-based perrhenates? Expert Synthesis

- What are the key steps in the operation of a vacuum chamber? Master the Process for Precision Control

- Why is a 'baking-out' pretreatment necessary for magnesium purification? Ensure Ultra-High Purity in Your Vacuum Distillation

- Why are heat insulation zones and sealing structures required at the discharge end of a vacuum sublimation furnace?