In short, the evacuation process uses a dedicated vacuum system to mechanically pump air and other gases out of a sealed furnace chamber. This system, composed of vacuum pumps, valves, and measurement gauges, reduces the internal pressure to a specific, pre-determined level before the heating cycle begins. The primary goal is to create a controlled, low-oxygen environment.

Evacuation is more than just removing air; it is the foundational step for achieving metallurgical control. By creating a near-vacuum, you prevent unwanted chemical reactions like oxidation, ensuring the material's integrity and surface finish are preserved at high temperatures.

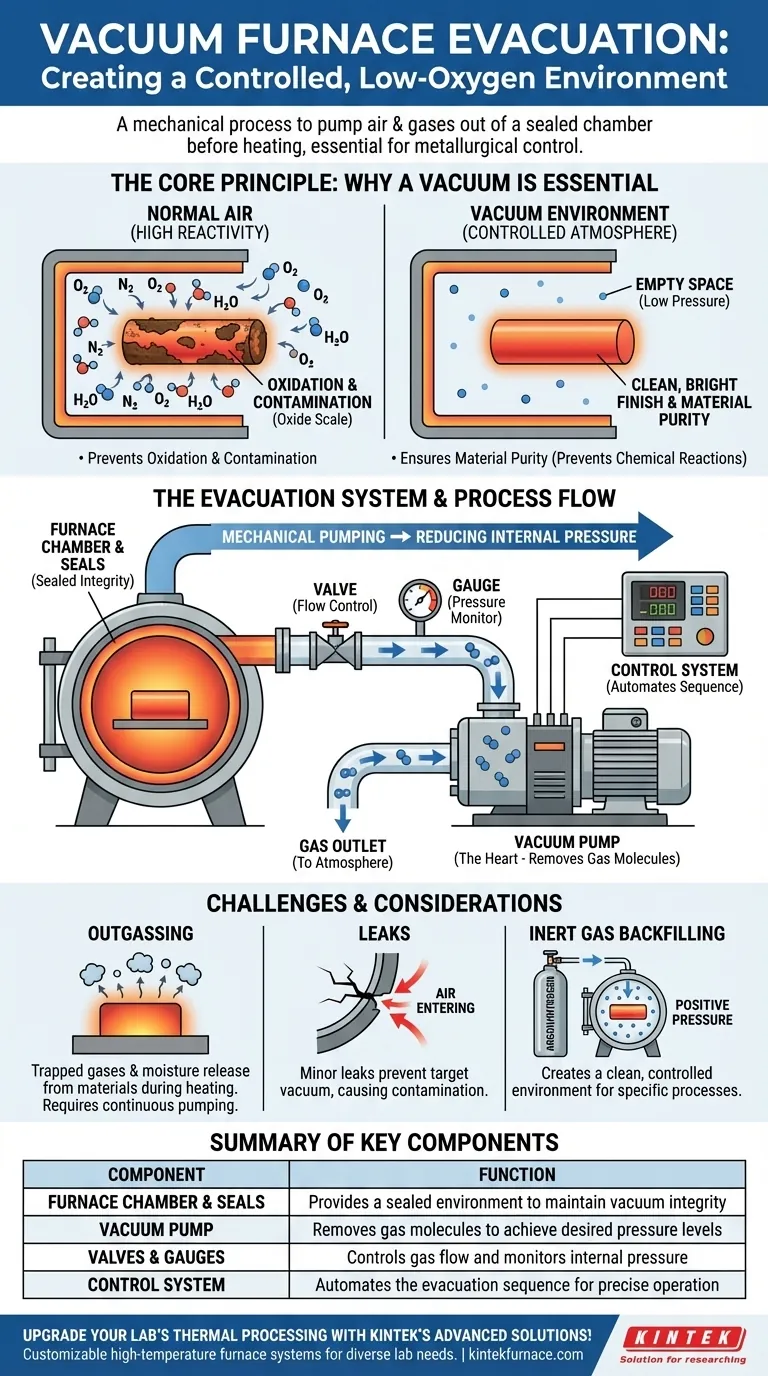

The Core Principle: Why a Vacuum is Essential

The primary reason for operating a furnace under vacuum is to control the atmosphere that surrounds the workpiece. At elevated temperatures, materials become significantly more reactive, and the gases present in normal air can cause undesirable effects.

Preventing Oxidation and Contamination

The most immediate benefit is the removal of oxygen. At high temperatures, oxygen will readily react with the surface of most metals, creating a layer of oxide scale. A vacuum environment effectively eliminates this possibility, resulting in a clean, bright part finish.

Ensuring Material Purity

Beyond just oxygen, the vacuum system removes other atmospheric gases and moisture. This prevents unwanted chemical reactions that could alter the material's composition, mechanical properties, or performance, which is critical for high-purity applications.

A Breakdown of the Evacuation System

The evacuation process is not the function of a single component but rather an integrated system working in concert.

The Furnace Chamber and Seals

The process begins with a sealed furnace chamber or "shell." The integrity of this vessel and its seals is critical to ensure that a vacuum can be achieved and maintained without leaks.

The Vacuum Pump

This is the heart of the system. The vacuum pump is responsible for physically removing gas molecules from the sealed chamber, transferring them to the outside atmosphere. The type and power of the pump determine how low a pressure (or how "deep" a vacuum) can be achieved.

Valves and Measurement Devices

Valves are used to isolate the furnace chamber from the pump and to control the flow of gases. A vacuum measuring device, or gauge, constantly monitors the pressure inside the chamber, providing the feedback needed to know when the target vacuum level has been reached.

The Control System

A modern vacuum furnace uses an automated control system. This system orchestrates the entire sequence, activating the pumps to begin evacuation and only allowing the heating elements to turn on after the required vacuum level is confirmed.

Understanding the Trade-offs and Common Pitfalls

While creating a vacuum is highly beneficial, the process involves key considerations and potential challenges that must be managed for successful operation.

Vacuum Level vs. Process Time

Achieving a very deep vacuum requires more powerful pumping systems and significantly more time. For many processes, a moderate vacuum that simply removes reactive oxygen is sufficient and more economical than pulling a "hard" vacuum.

The Problem of Outgassing

As the workpiece and the internal furnace components heat up, they can release trapped gases and moisture in a process called outgassing. The vacuum system must continue to operate during the heating cycle to remove these released gases and maintain the desired pressure.

Leaks in the System

Even a minor leak in a seal or fitting can prevent the furnace from reaching its target vacuum level. This allows oxygen and other contaminants to enter the chamber, defeating the purpose of the process and potentially ruining the workpiece.

Inert Gas Backfilling

A vacuum is not always the final processing atmosphere. Often, the chamber is evacuated to remove contaminants and then backfilled with a high-purity inert gas, like argon or nitrogen. This creates a clean, positive-pressure environment for specific processes like brazing or gas quenching.

Making the Right Choice for Your Goal

The specific parameters of the evacuation process should be tailored to the material being processed and the desired outcome.

- If your primary focus is preventing surface oxidation (e.g., bright annealing): A moderate vacuum to remove the bulk of atmospheric oxygen is often sufficient and efficient.

- If your primary focus is high-purity processing (e.g., medical implant manufacturing or aerospace brazing): A deeper vacuum is critical to remove trace contaminants and manage outgassing effectively.

- If your primary focus is controlled heating and cooling: Use evacuation to create a clean slate, then backfill with an inert gas to provide uniform heat transfer and enable rapid gas-quenching.

Ultimately, mastering the evacuation process is fundamental to achieving predictable, high-quality results in modern thermal processing.

Summary Table:

| Component | Function |

|---|---|

| Furnace Chamber & Seals | Provides a sealed environment to maintain vacuum integrity |

| Vacuum Pump | Removes gas molecules to achieve desired pressure levels |

| Valves & Gauges | Controls gas flow and monitors internal pressure |

| Control System | Automates the evacuation sequence for precise operation |

Upgrade your lab's thermal processing with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and results. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity