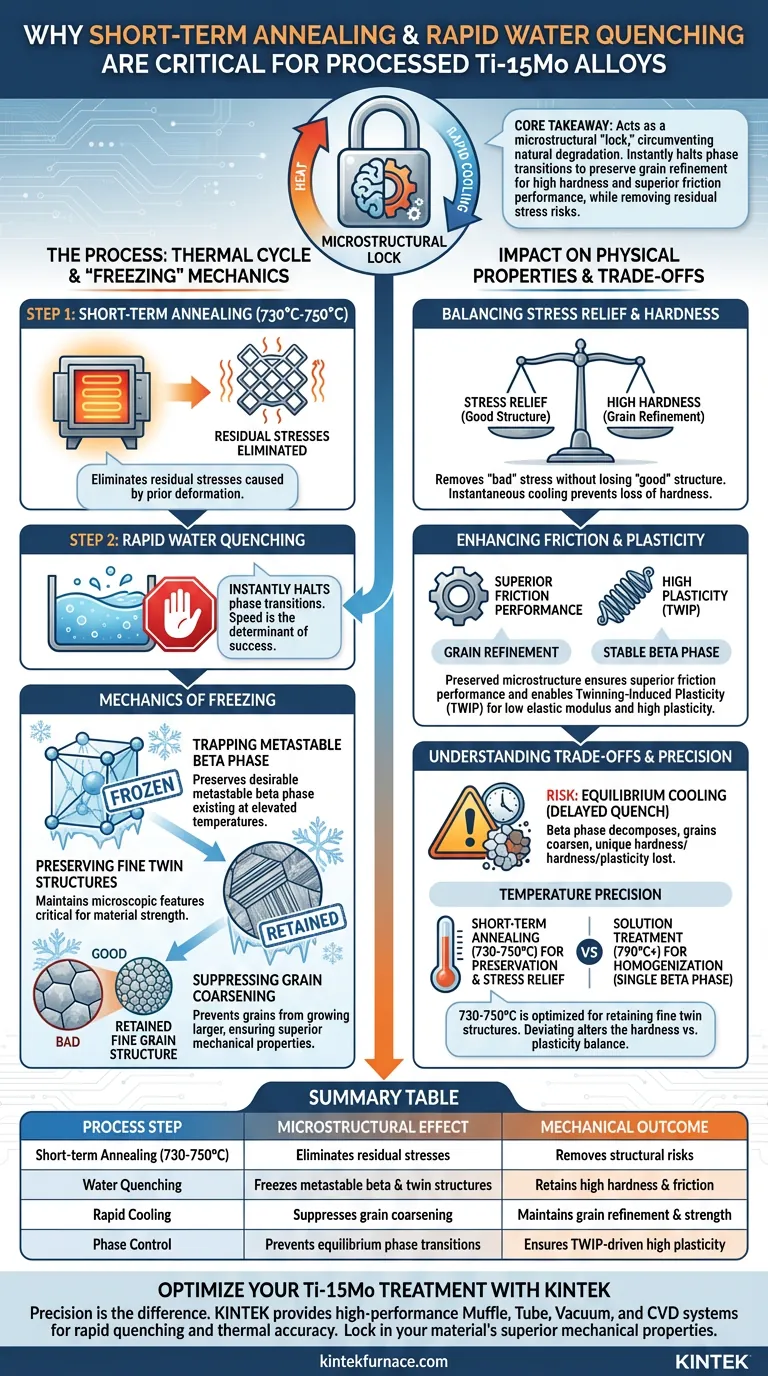

Short-term annealing followed by rapid water quenching is the definitive method for stabilizing the favorable microstructure of processed Ti-15Mo alloys. This specific thermal cycle eliminates residual stresses caused by prior deformation while simultaneously "freezing" the high-temperature metastable beta phase and fine twin structures before they can decay or grow.

Core Takeaway This process acts as a microstructural "lock," circumventing the natural degradation that occurs during slow cooling. By instantly halting phase transitions, it preserves grain refinement to ensure high hardness and superior friction performance, while still removing the structural risks associated with residual stress.

The Mechanics of Microstructural "Freezing"

Trapping the Metastable Beta Phase

At elevated temperatures (specifically 730°C to 750°C), Ti-15Mo alloys exist in a desirable metastable beta phase.

If allowed to cool slowly, the alloy would undergo equilibrium phase transitions, changing its fundamental structure. Water quenching acts as a thermal brake, instantly dropping the temperature to freeze this beta phase in place at room temperature.

Preserving Fine Twin Structures

Processed Ti-15Mo alloys often contain "fine twin structures"—microscopic features generated during deformation that contribute significantly to the material's strength.

Short-term annealing maintains these structures. The subsequent rapid cooling ensures these newly formed twins are retained rather than dissolving or altering, which is critical for maintaining the alloy's specific mechanical advantages.

Suppressing Grain Coarsening

Heat generally causes grains within a metal to grow larger (coarsen), which typically reduces strength and hardness.

The rapid nature of the water quenching process effectively suppresses microstructural coarsening. By cutting the heat exposure short and cooling instantly, the material retains a fine-grained structure, which is directly linked to superior mechanical properties.

Impact on Physical Properties

Balancing Stress Relief and Hardness

The primary challenge in processing these alloys is removing the "bad" stress without losing the "good" structure.

The short-term annealing phase (730°C–750°C) provides enough thermal energy to eliminate the residual stresses caused by cyclic deformation. However, because the cooling is instantaneous, this stress relief does not come at the cost of grain refinement, ensuring the material retains high hardness.

Enhancing Friction Performance

The friction performance of Ti-15Mo is heavily dependent on its surface microstructure.

By preserving the grain refinement and fine twin structures, the annealing-quenching cycle ensures the material exhibits superior friction performance. A coarser microstructure resulting from slower cooling would likely degrade these wear-resistant characteristics.

Enabling Plasticity Mechanisms

While the primary goal of this specific 730°C–750°C range is balancing hardness and stress, the retention of the metastable beta phase is also essential for plasticity.

A stable beta-phase structure allows for effects such as Twinning-Induced Plasticity (TWIP). This ensures that while the material is hard, it maintains a low elastic modulus and high plasticity, preventing it from becoming brittle.

Understanding the Trade-offs

The Risk of Equilibrium Cooling

The most critical pitfall in this process is a delay in quenching.

Any hesitation allows the material to enter "equilibrium phase transitions." If this occurs, the beta phase decomposes, grains coarsen, and the unique combination of high hardness and plasticity is lost. Speed is not just a variable; it is the determinant of success.

Temperature Precision

There is a distinct difference between "short-term annealing" for preservation (730°C–750°C) and higher-temperature solution treatments (e.g., 790°C).

While higher temperatures (790°C) are useful for homogenization and creating a single beta-phase structure, the specific 730°C–750°C range described is optimized for retaining fine twin structures alongside stress relief. Deviating from this range alters the final balance of hardness vs. plasticity.

Making the Right Choice for Your Goal

To optimize the heat treatment of your Ti-15Mo alloy, align the process parameters with your specific performance requirements:

- If your primary focus is High Hardness and Friction Performance: Adhere strictly to the short-term annealing at 730°C–750°C followed by immediate water quenching to preserve fine twin structures.

- If your primary focus is Homogenization and Maximum Plasticity: Consider higher temperature solution treatments (around 790°C) to achieve a uniform single beta-phase structure, accepting potential changes in hardness.

- If your primary focus is Stress Relief: Ensure the annealing is sufficient to remove cyclic deformation stresses but follows with rapid quenching to prevent the loss of mechanical strength.

The success of Ti-15Mo processing relies on the speed of the quench; you must freeze the structure to lock in performance.

Summary Table:

| Process Step | Microstructural Effect | Mechanical Outcome |

|---|---|---|

| Short-term Annealing (730-750°C) | Eliminates residual stresses from deformation | Removes structural risks/brittleness |

| Water Quenching | "Freezes" metastable beta phase & twin structures | Retains high hardness & friction performance |

| Rapid Cooling | Suppresses grain coarsening | Maintains grain refinement & strength |

| Phase Control | Prevents equilibrium phase transitions | Ensures TWIP-driven high plasticity |

Optimize Your Ti-15Mo Alloy Treatment with KINTEK

Precision is the difference between material success and failure. At KINTEK, we understand that for Ti-15Mo alloys, speed and temperature control are non-negotiable. Backed by expert R&D and world-class manufacturing, we provide high-performance Muffle, Tube, Vacuum, and CVD systems designed to deliver the rapid quenching and thermal accuracy your alloys require.

Whether you need customizable lab furnaces for grain refinement or high-temp systems for stress relief, KINTEK offers the specialized equipment to lock in your material's superior mechanical properties.

Ready to elevate your heat treatment results? Contact our experts today for a custom solution!

Visual Guide

References

- Tiewei Xu, Bin-Jiang Lv. The {332}<113> Twinning Behavior of a Ti-15Mo Medical Alloy during Cyclic Deformation and Its Effect on Microstructure and Performance. DOI: 10.3390/ma17071462

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- How does vacuum heat treating work in terms of temperature and time control? Master Precise Material Transformations

- What advantages do SPS systems offer over traditional sintering for high-entropy diboride? Achieve 98%+ Density Rapidly

- How is a laboratory vacuum drying oven utilized in the production of shape-stabilized phase change materials?

- What are the limitations of high vacuum furnaces? Understand Costs, Time, and Material Challenges

- What role do vacuum pumping systems play in vacuum furnaces? Ensure Purity and Control in Thermal Processes

- What is the first step in the vacuum sintering process? Master the Key to High-Performance Parts

- What advantages does vacuum hardening offer? Achieve Superior, Distortion-Free Heat Treatment

- What advantages does laser active brazing offer compared to traditional furnace brazing? Precision Sealing Explored