In short, vacuum hardening delivers superior components by eliminating the atmospheric reactions that cause surface defects and distortion in conventional heat treatment. This process provides exceptional control over the final part's dimensions, surface finish, and metallurgical properties, often removing the need for costly secondary operations.

The core advantage of vacuum hardening is not just one specific benefit, but the achievement of a clean, dimensionally accurate, and metallurgically sound component directly from the furnace. It transforms heat treatment from a potentially crude necessity into a precise, value-adding manufacturing step.

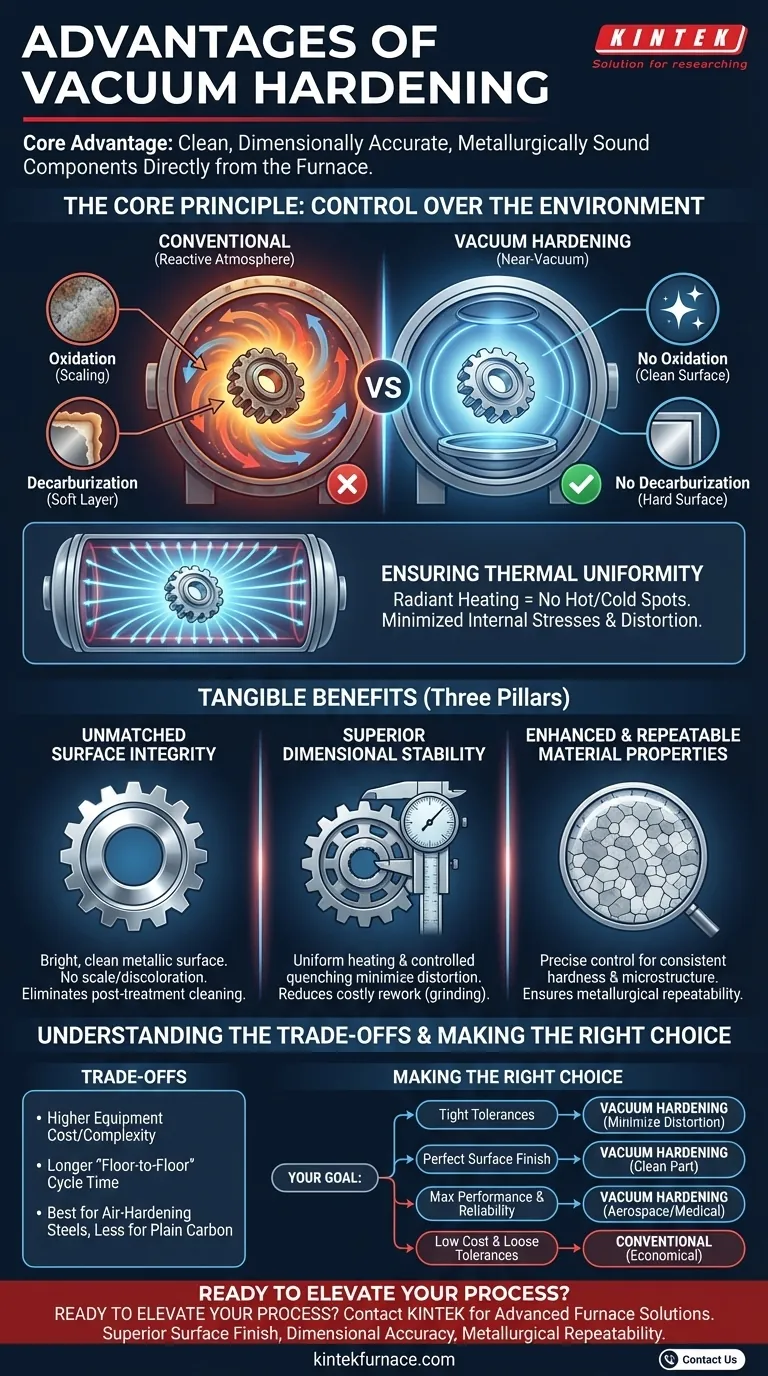

The Core Principle: Control Over the Environment

To understand the benefits of vacuum hardening, you must first understand its fundamental difference from traditional methods. Conventional hardening occurs in furnaces with active atmospheres (gases), which inevitably react with the hot metal surface.

Vacuum hardening removes this variable. By conducting the process in a near-vacuum, we create a pristine, non-reactive environment.

Eliminating Atmospheric Reactions

The primary goal of the vacuum is to remove oxygen and other reactive gases. This prevents two major problems: oxidation (scaling) and decarburization.

Oxidation creates a layer of scale on the part's surface that must be cleaned off, often through abrasive methods like sandblasting, which can affect final dimensions and finish.

Decarburization is the loss of carbon from the surface of steel, resulting in a soft outer layer with poor wear resistance and fatigue life. A vacuum environment completely prevents this.

Ensuring Thermal Uniformity

Vacuum furnaces provide radiant heating, which is incredibly uniform. Without hot or cold spots from convection currents found in atmospheric furnaces, the entire component heats and cools at a highly controlled and consistent rate.

This thermal precision is the key to minimizing internal stresses, which are the primary cause of distortion.

The Tangible Benefits of a Controlled Process

This precise control over the environment and temperature profile translates directly into measurable improvements in the final product.

Unmatched Surface Integrity

Parts emerge from a vacuum furnace with a bright, clean, metallic surface. There is no scale or discoloration.

This eliminates the need for post-treatment cleaning operations, saving time, reducing costs, and preserving the component's as-machined surface finish and sharp edges.

Superior Dimensional Stability

Because heating is uniform and quenching can be precisely managed using inert gas pressure and velocity, distortion is minimized.

For parts with complex geometries or tight tolerances, this is a critical advantage. It reduces or eliminates the need for expensive and time-consuming rework like grinding or straightening to bring the part back into specification.

Enhanced and Repeatable Material Properties

The process allows for exact control over heating rates, soak times, and quenching speeds. This precision ensures you achieve the desired hardness and microstructure consistently across the entire part and from batch to batch.

This metallurgical repeatability is essential for high-performance applications where properties like tensile strength and corrosion resistance are non-negotiable. The process is computer-controlled, ensuring results are consistent and meet stringent standards like CQI-9.

Understanding the Trade-offs

While powerful, vacuum hardening is not a universal solution. An objective evaluation requires acknowledging its limitations.

Equipment Cost and Complexity

Vacuum furnaces are a significant capital investment compared to standard atmospheric furnaces. They require more complex support systems, including powerful pumps and advanced control systems, which translates to a higher processing cost per part.

Cycle Time Considerations

Achieving the required vacuum level adds time to the beginning of each cycle. While the heating and quenching can be rapid, the overall "floor-to-floor" time may be longer than some conventional processes, impacting high-volume throughput.

Process Suitability

Vacuum hardening is ideal for air-hardening tool steels and certain stainless steels. It is less suitable for plain carbon steels that require extremely fast liquid quenching (like water or oil) to achieve full hardness, as gas quenching is inherently slower.

Making the Right Choice for Your Goal

Selecting the right heat treatment method depends entirely on the specific requirements of your component.

- If your primary focus is tight dimensional tolerance: Vacuum hardening is the superior choice to minimize distortion and avoid post-treatment grinding.

- If your primary focus is a perfect surface finish: Use vacuum hardening to get a clean, bright part directly from the furnace without needing secondary cleaning.

- If your primary focus is maximum performance and reliability: The metallurgical precision and repeatability of vacuum hardening make it ideal for critical aerospace, medical, or tooling components.

- If your primary focus is low cost on a simple part with loose tolerances: A conventional atmospheric hardening process is likely more economical and perfectly adequate.

Ultimately, choosing vacuum hardening is an investment in predictability, quality, and reducing the total cost of producing a finished part.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Surface Integrity | Eliminates oxidation and decarburization, no need for post-cleaning |

| Dimensional Stability | Minimizes distortion through uniform heating and controlled quenching |

| Metallurgical Properties | Ensures consistent hardness and microstructure for high-performance parts |

| Process Control | Computer-controlled for repeatable results, ideal for tight tolerances |

Ready to elevate your heat treatment process with precision and reliability? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements. Whether you're in aerospace, medical, or tooling, our vacuum hardening solutions deliver superior surface finish, dimensional accuracy, and metallurgical repeatability. Contact us today to discuss how we can help you achieve distortion-free, high-quality components and reduce total production costs!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What role does an industrial-grade vacuum sintering furnace play in the final molding of 17-4 PH stainless steel parts?

- What are the essential requirements for a high-temperature vacuum furnace? Optimize Your Metal Solidification Research

- What is the function of a Spark Plasma Sintering (SPS) system in the preparation of porous tungsten gradient precursors?

- What function does a high vacuum sintering furnace serve in Ti6Al4V densification? Achieve Superior Material Purity

- What are the functions of the vacuum chamber in the furnace? Ensure Purity and Precision in High-Temp Processes

- What processes are performed in a high-temperature vacuum furnace? Achieve Purity and Precision in Material Processing

- What is the purpose of using a vacuum oven in two-step magnesium sintering? Ensure Pore Integrity & Prevent Oxidation

- What are the main features and advantages of a vacuum heat treatment furnace? Achieve Superior Material Quality & Efficiency