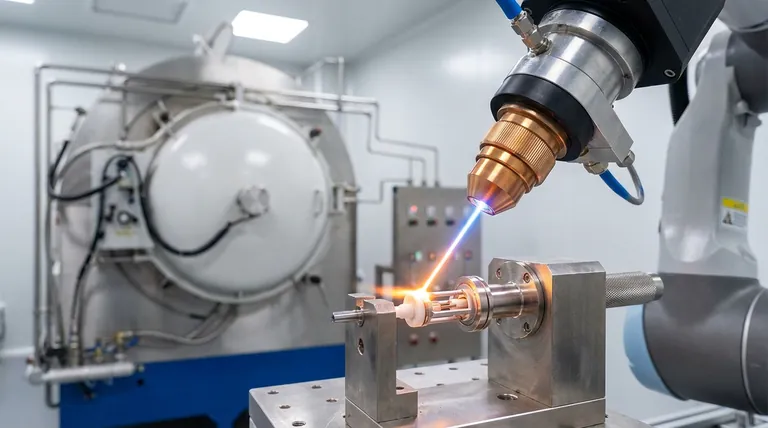

Laser active brazing outperforms traditional furnace brazing in the manufacturing of micro-energy sensor feedthroughs primarily through its ability to deliver localized, high-precision energy. Unlike furnace brazing, which exposes the entire assembly to high temperatures, laser brazing focuses heat strictly on the joint interface. This targeted approach melts the brazing alloy while keeping the surrounding metal components relatively cool, drastically minimizing thermal distortion.

By decoupling the sealing process from the bulk heating of the component, laser active brazing eliminates the macro-thermal stresses typical of furnace processing. This ensures the dimensional integrity of sensitive micro-sensors and significantly enhances their reliability under thermal cycling.

The Physics of Localized Energy Input

Precision Energy Application

Laser active brazing utilizes a focused beam to input energy with extreme precision. This allows manufacturers to target the specific area where the seal is required without affecting the rest of the assembly.

Minimizing the Heat-Affected Zone

A critical advantage of this method is the creation of an extremely small heat-affected zone (HAZ). In traditional furnace brazing, the entire component reaches the brazing temperature, altering material properties globally. Laser brazing confines these microstructural changes to the immediate joint area.

Controlling Overall Temperature Rise

Because the energy input is so localized, the overall temperature rise of the metal components is minimized. The bulk of the micro-sensor remains at a much lower temperature than the melting point of the brazing alloy, protecting sensitive internal elements from thermal damage.

Mitigating Stress and Distortion

Reducing Macro-Thermal Stress

The primary driver of failure in traditional brazing is the stress caused by the expansion and subsequent contraction of metal parts as they heat and cool globally. Laser active brazing significantly reduces this macro-thermal stress caused by metal contraction.

Improving Dimensional Accuracy

When the bulk of the component does not expand significantly, the geometry of the final part remains stable. This results in superior dimensional accuracy, which is critical for the tight tolerances required in micro-energy sensor feedthroughs.

Enhancing Long-Term Reliability

Thermal Cycle Endurance

Joints formed with high residual stress are prone to failure when subjected to operational temperature changes. By minimizing initial stress during fabrication, laser brazing improves the thermal cycle reliability of the joint.

Sealing Integrity

The localized melting allows for a hermetic seal to form without the risk of warping the mating surfaces. This ensures a consistent, leak-proof barrier essential for sensor performance.

Understanding the Trade-offs

Line-of-Sight Requirements

While laser brazing offers precision, it requires direct access to the joint. Unlike furnace brazing, which heats by convection or radiation throughout a chamber, the laser beam must have a clear physical path to the brazing alloy.

Process Complexity

Achieving the "high-precision energy input" described requires sophisticated control systems. This introduces a level of process complexity regarding alignment and beam focus that is generally higher than the "batch and bake" nature of furnace brazing.

Making the Right Choice for Your Goal

To determine if laser active brazing is the correct manufacturing solution for your specific application, consider your priority metrics:

- If your primary focus is dimensional stability: Laser brazing is the superior choice because it prevents the global metal contraction that warps components.

- If your primary focus is component longevity: The reduction in macro-thermal stress provided by laser brazing will directly translate to better performance during repetitive thermal cycling.

For micro-energy sensors where precision is non-negotiable, the ability to isolate heat is the single most critical factor in ensuring manufacturing success.

Summary Table:

| Feature | Laser Active Brazing | Traditional Furnace Brazing |

|---|---|---|

| Heat Input | Highly Localized (Focal Point) | Global (Entire Component) |

| Thermal Stress | Minimal Macro-Stress | High Stress from Contraction |

| Heat-Affected Zone | Extremely Small | Large/Global |

| Dimensional Accuracy | Superior Stability | High Risk of Distortion |

| Component Safety | Protects Heat-Sensitive Parts | Risk of Thermal Damage |

| Complexity | High (Requires Line-of-Sight) | Lower (Batch Processing) |

Elevate Your Manufacturing Precision with KINTEK

Are you struggling with thermal distortion in your micro-sensor assemblies? KINTEK provides the cutting-edge thermal technology needed to ensure your components meet the strictest dimensional tolerances. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable for your unique laboratory or industrial needs. Whether you require precise localized heating or controlled atmosphere furnace brazing, our experts are here to help you optimize your process for maximum reliability.

Ready to enhance your lab's efficiency and product longevity? Contact KINTEK today to discuss your custom solution!

References

- Jian Feng, Antonio Hurtado. Active Brazing for Energy Devices Sealing. DOI: 10.3390/jeta2010001

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

People Also Ask

- What role does vacuum radiation play in CAP capping? Optimize Ingot Integrity and Material Yield

- Why is graphite felt replacing graphite board in vacuum furnace insulation? Boost Efficiency & Durability

- How is a two-stage heating process implemented in plasma nitriding equipment? Master Surface Consistency

- How does uniform heating and cooling benefit materials in vacuum furnaces? Prevent Stress and Boost Performance

- What factors should be considered when choosing a vacuum furnace? Optimize Your Material Processing with Expert Tips

- What are the challenges of relying solely on a vacuum in furnace applications? Overcome Key Operational Hurdles

- What industries commonly use vacuum chamber furnaces? Essential for Aerospace, Medical, and More

- Why is a high-vacuum probe station necessary for SnS2 analysis? Ensure Pure Electrical Characterization