At its core, uniform heating and cooling in a vacuum furnace is the single most critical factor for preventing internal stress and physical distortion in treated materials. This thermal consistency ensures that the final component possesses the intended strength, durability, and dimensional accuracy required for its application, eliminating defects that could lead to premature failure.

Uniform thermal processing is not merely a procedural step; it is the fundamental principle that guarantees the metallurgical integrity and performance of a component. By preventing the formation of internal stresses, it ensures the material behaves predictably under real-world operating conditions.

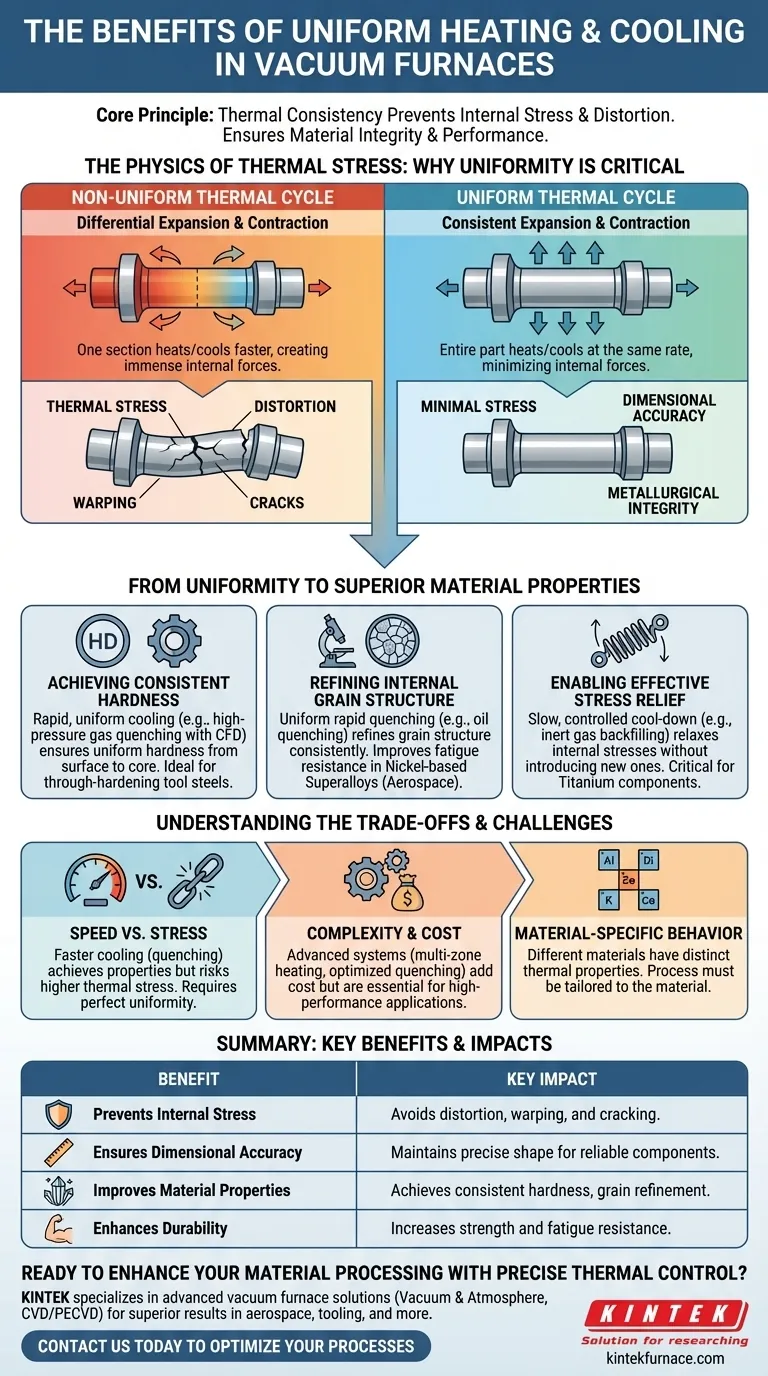

The Physics of Thermal Stress: Why Uniformity is Non-Negotiable

All materials expand when heated and contract when cooled. The challenge in any thermal process is managing this physical change. When temperature changes are not uniform across a component, it creates a cascade of problems that compromise the material's integrity.

The Problem of Differential Expansion

When one section of a part heats or cools faster than another, it tries to expand or contract at a different rate. The cooler, more rigid sections physically constrain the hotter, expanding sections (and vice versa), creating immense internal forces.

How Internal Stress Forms

These internal forces are known as thermal stress. If this stress exceeds the material's elastic limit, it will result in permanent, irreversible changes to the part's shape.

The Result: Distortion, Warping, and Cracks

This permanent change manifests as distortion or warping. In more extreme cases, especially with brittle materials or extremely rapid temperature changes, the stress can become so great that it causes microscopic or even catastrophic cracking.

From Uniformity to Superior Material Properties

Controlling the rate of heating and cooling is not just about preventing defects; it is a precise tool used to engineer specific, desirable material characteristics. The uniformity of the process dictates the consistency of these properties.

Achieving Consistent Hardness

For applications like through-hardening tool steels, rapid cooling is essential. A vacuum furnace with high-pressure gas quenching, using nozzles optimized with computational fluid dynamics (CFD), ensures the entire part cools at the same rate. This uniformity guarantees consistent hardness from the surface to the core.

Refining Internal Grain Structure

In materials like nickel-based superalloys used in aerospace, rapid oil quenching refines the metallic grain structure. Uniform cooling ensures this refinement is consistent throughout the component, which is critical for improving fatigue resistance and high-temperature strength.

Enabling Effective Stress Relief

Conversely, for stress-relief annealing of titanium components, a slow, controlled cool-down is required. Backfilling the vacuum furnace with an inert gas allows for a gradual and highly uniform temperature reduction, effectively relaxing any internal stresses from previous manufacturing steps without introducing new ones.

Understanding the Trade-offs and Challenges

While the goal is always uniformity, the path to achieving it involves balancing competing requirements and acknowledging the limitations of the process.

Speed vs. Stress

Rapid cooling (quenching) is necessary to achieve certain metallurgical properties like hardness, but it inherently carries the highest risk of inducing thermal stress. The faster the quench, the more critical perfect uniformity becomes to prevent distortion or cracking.

Complexity and Cost

Systems designed for high-precision thermal uniformity are more complex and expensive. Features like advanced furnace designs, multi-zone heating controls, and sophisticated gas or liquid quenching systems add significant cost but are essential for high-performance applications.

Material-Specific Behavior

Different materials have vastly different thermal conductivity and coefficients of thermal expansion. A process optimized for a block of tool steel will not work for a thin-walled titanium fabrication. The process must be tailored to the material's specific properties to be successful.

How to Apply This to Your Process

The ideal thermal cycle depends entirely on the material you are working with and your desired outcome. Your choice of heating and cooling strategy should be deliberate and aligned with the end goal.

- If your primary focus is maximizing hardness in tool steels: You need a system capable of high-pressure gas quenching that ensures a rapid and uniform cooling rate across the entire part.

- If your primary focus is grain refinement in superalloys for fatigue life: You should prioritize a furnace with a rapid liquid quenching system to achieve the necessary cooling speeds consistently.

- If your primary focus is dimensional stability and stress relief: You must use a process with precisely controlled, slow cooling capabilities, often involving inert gas backfilling, to prevent distortion.

Mastering thermal uniformity is the key to unlocking the full potential of your materials and producing components you can trust.

Summary Table:

| Benefit | Key Impact |

|---|---|

| Prevents Internal Stress | Avoids distortion, warping, and cracking in materials |

| Ensures Dimensional Accuracy | Maintains precise shape and size for reliable components |

| Improves Material Properties | Achieves consistent hardness, grain refinement, and stress relief |

| Enhances Durability | Increases strength and fatigue resistance for demanding applications |

Ready to enhance your material processing with precise thermal control? KINTEK specializes in advanced vacuum furnace solutions, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, backed by deep customization to meet your unique needs. Our expertise in uniform heating and cooling ensures superior results for industries like aerospace and tooling. Contact us today to discuss how we can optimize your thermal processes for better performance and reliability!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing