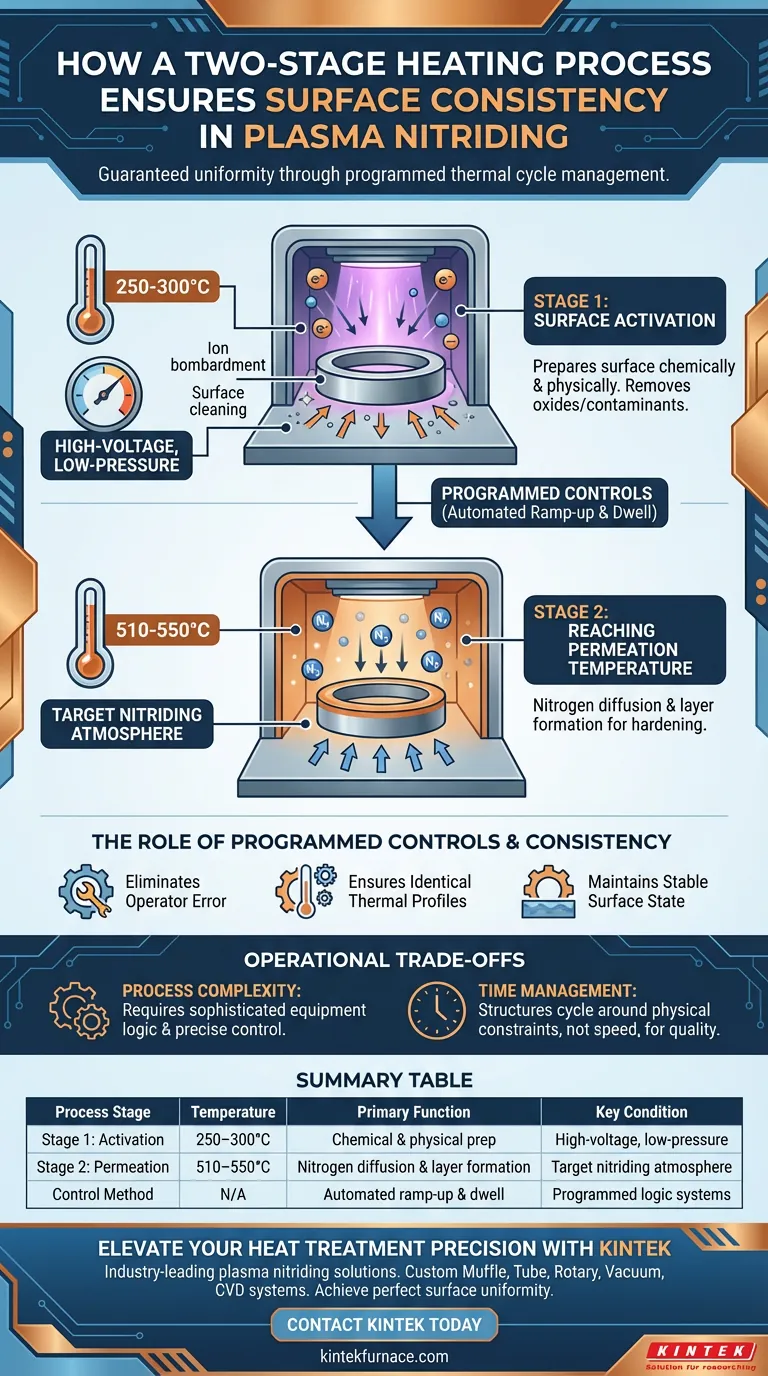

A two-stage heating process in plasma nitriding is implemented through programmed controls that rigorously manage the thermal cycle to guarantee uniformity. This method divides the heating curve into two distinct phases: an initial surface activation stage at 250–300°C under high-voltage, low-pressure conditions, followed by a secondary rise to the final permeation temperature of 510–550°C.

By decoupling surface activation from the final heating phase, this step-wise approach prevents the thermal and chemical inconsistencies that can occur during rapid, single-stage heating. It ensures the workpiece enters the final nitriding phase with a uniform surface state, which is critical for predictable hardening results.

The Mechanics of the Two-Stage Cycle

Stage 1: Surface Activation

The process begins by placing the workpiece in a specific environment designed to prepare the material.

The equipment establishes a high-voltage, low-pressure atmosphere.

During this phase, the temperature is raised to a moderate range of 250 to 300 degrees Celsius.

This stage focuses on "activating" the surface, ensuring it is chemically and physically prepared to accept nitrogen diffusion later in the process.

Stage 2: Reaching Permeation Temperature

Once the surface is successfully activated, the equipment transitions to the second stage.

The temperature is increased further until it reaches the target permeation range of 510 to 550 degrees Celsius.

This is the temperature at which the actual nitriding (nitrogen diffusion) occurs most effectively.

Ensuring Consistency Through Precision

The Role of Programmed Controls

The success of this method relies entirely on automation rather than manual adjustment.

Programmed controls manage the transition between stages, ensuring the ramp-up rates and dwell times are executed exactly as defined.

This eliminates operator error and ensures that every batch undergoes the exact same thermal profile.

Stabilizing the Surface State

The primary engineering goal of this two-stage approach is stability.

By halting the heating process at the activation stage, the equipment ensures the surface state of the workpiece remains consistent across complex geometries.

This prevents scenarios where the core and surface might be at drastically different states, or where impurities interfere with the nitriding layer formation.

Understanding the Operational Trade-offs

Process Complexity

Implementing a two-stage process requires equipment capable of sophisticated logic and precise environmental control.

Simple, single-stage furnaces cannot replicate this stepped activation without significant manual intervention, which introduces risk.

Time Management

This step-wise method inherently structures the cycle time around physical constraints rather than pure speed.

While it guarantees quality, the mandatory dwell time at the activation stage (250–300°C) means the total cycle cannot be arbitrarily rushed without sacrificing surface consistency.

Making the Right Choice for Your Goal

To effectively utilize this heating strategy, you must align your equipment capabilities with your material requirements.

- If your primary focus is surface uniformity: Prioritize equipment that features robust programmed controls capable of automating the high-voltage transition between the activation and permeation stages.

- If your primary focus is process verification: Ensure your thermal profiling can distinctively log the hold time at 250–300°C separate from the final soak at 510–550°C to validate that activation occurred.

Precision in the heating curve is the single greatest predictor of consistency in the final hardened layer.

Summary Table:

| Process Stage | Temperature Range | Primary Function | Key Condition |

|---|---|---|---|

| Stage 1: Activation | 250–300°C | Chemical & physical surface preparation | High-voltage, low-pressure |

| Stage 2: Permeation | 510–550°C | Nitrogen diffusion & layer formation | Target nitriding atmosphere |

| Control Method | N/A | Automated ramp-up and dwell times | Programmed logic systems |

Elevate Your Heat Treatment Precision with KINTEK

Don't settle for inconsistent hardening results. KINTEK provides industry-leading plasma nitriding solutions backed by expert R&D and advanced manufacturing. Whether you require Muffle, Tube, Rotary, Vacuum, or CVD systems, our equipment is fully customizable to meet your unique material requirements and two-stage heating needs.

Our systems empower lab and industrial professionals to achieve perfect surface uniformity and predictable hardening depth. Contact KINTEK today to discuss your custom furnace needs and see how our programmed control technology can transform your production quality.

Visual Guide

References

- Nguyen Thai Van, Le Hong Ky. The Influence of Plasma Nitriding Technology Parameters on the Hardness of 18XГT Steel Parts. DOI: 10.48084/etasr.7089

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the key features of a high-quality vacuum heat treatment furnace? Ensure Superior Heat Treatment Precision

- What are the applications of furnace brazing in the medical and pharmaceutical industries? Achieve Sterile, High-Strength Joining

- What are the main components of a drop-bottom quench furnace? Essential Parts for Rapid Heat Treatment

- Why is vacuum heat treatment necessary? Achieve Superior Material Purity and Performance

- What is the difference between vacuum sintering and atmosphere sintering? Choose the Right Method for Your Materials

- What are the technical advantages of using a high vacuum furnace for Si3N4/Al-Cu composites? Superior Sintering Quality

- Why are graphite fixtures and holders important in vacuum furnaces? Unlock Precision & Durability

- What are some common industrial uses of vacuum furnaces? Enhance Material Quality and Performance