In short, furnace brazing is critical for manufacturing high-integrity medical devices, including orthopedic implants, surgical instruments, and diagnostic equipment components. Its value comes from creating exceptionally strong, sterile, and biocompatible joints in a highly controlled environment, while furnaces in the pharmaceutical sector are primarily used for material testing and quality control.

The core principle is not just joining metal, but doing so with absolute cleanliness and precision. Furnace brazing is the preferred method because its controlled vacuum or atmospheric environment prevents contamination, a non-negotiable requirement for any device used in or on the human body.

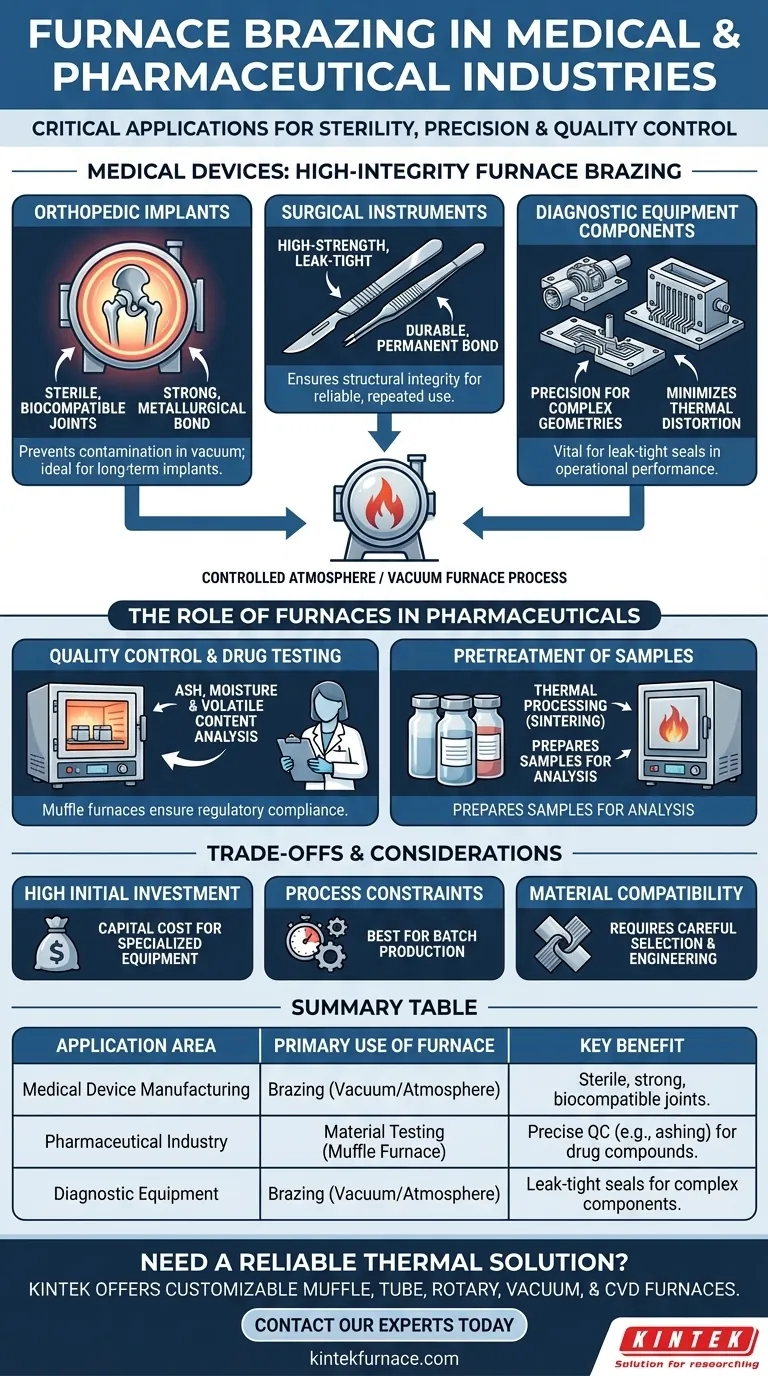

Why Furnace Brazing is Essential for Medical Devices

Furnace brazing is a process where metal parts are joined using a filler metal with a lower melting point than the base components. The entire assembly is heated in a controlled furnace, allowing the filler to flow into the joint via capillary action and form a strong, metallurgical bond upon cooling.

Ensuring Biocompatibility and Sterility

The most critical advantage for medical applications is the environment. Performing the process inside a vacuum furnace removes oxygen and other potential contaminants.

This prevents oxidation and ensures the final joint is clean and sterile, making it safe for direct contact with human tissue in devices like orthopedic implants.

Creating High-Strength, Leak-Tight Joints

Furnace brazing creates a solid, permanent bond between components. This structural integrity is essential for the durability of surgical tools and the long-term reliability of implants.

For diagnostic equipment, such as devices with micro-channel heat exchangers, these leak-tight seals are vital for operational performance and safety.

Precision for Complex Geometries

The process heats the entire assembly uniformly, which minimizes thermal stress and distortion. This allows for the joining of intricate and delicate components without compromising their precise shapes.

This makes it ideal for manufacturing complex surgical instruments where dimensional accuracy is paramount.

The Role of Furnaces in Pharmaceuticals

While furnace brazing is about joining materials, the use of furnaces in the pharmaceutical industry focuses more on processing and analysis. This is a key distinction.

Quality Control and Drug Testing

Muffle furnaces, a specific type of high-temperature furnace, are standard tools in pharmaceutical labs.

They are used for critical quality control procedures, such as determining the ash, moisture, and volatile content of drug compounds and raw materials to ensure they meet strict regulatory standards.

Pretreatment of Medical Samples

Furnaces are also used for the thermal pretreatment of medical samples. This can involve high-temperature sintering or other thermal processing steps required to prepare a sample for further analysis.

Understanding the Trade-offs and Considerations

While powerful, the furnace brazing process is not a universal solution. Understanding its limitations is key to its proper application.

High Initial Investment

Vacuum furnaces and the associated control systems represent a significant capital investment. The process requires specialized equipment and skilled operators.

Process Constraints

Furnace brazing is best suited for batch production, as each cycle involves heating and cooling the entire furnace chamber. It is less efficient for one-off jobs or rapid prototyping.

Material Compatibility

The success of a brazed joint depends heavily on the compatibility between the base metals and the filler metal. This requires careful material selection and engineering to ensure a strong, reliable bond is formed.

Making the Right Choice for Your Goal

To apply this knowledge effectively, align the process with your primary objective.

- If your primary focus is manufacturing sterile, high-integrity medical devices: Vacuum furnace brazing is the definitive choice for creating clean, strong, and biocompatible joints for implants and surgical tools.

- If your primary focus is pharmaceutical quality control and material analysis: High-temperature muffle furnaces are the industry standard for sample preparation and essential testing procedures like ashing.

- If your primary focus is building complex diagnostic equipment: Furnace brazing provides a reliable method for creating the precise, leak-tight bonds required for components like heat exchangers.

Ultimately, the controlled thermal environment of a furnace is the key enabler for achieving the uncompromising standards of safety and precision required in these demanding fields.

Summary Table:

| Application Area | Primary Use of Furnace | Key Benefit |

|---|---|---|

| Medical Device Manufacturing | Brazing (Vacuum/Atmosphere) | Sterile, strong, and biocompatible joints for implants and instruments. |

| Pharmaceutical Industry | Material Testing (Muffle Furnace) | Precise quality control (e.g., ashing) for drug compounds and materials. |

| Diagnostic Equipment | Brazing (Vacuum/Atmosphere) | Leak-tight seals for complex components like micro-channel heat exchangers. |

Need a furnace solution for your critical medical or pharmaceutical application?

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD furnace systems. Our lab high-temp furnaces are all customizable for your unique needs, whether you require sterile brazing for medical devices or precise thermal processing for pharmaceutical QA.

Contact our experts today to discuss how we can provide a reliable thermal solution for your project.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity