A high vacuum environment is strictly required for sintering Ti-6Al-4V due to the extreme chemical reactivity of titanium and its alloying elements at elevated temperatures. Without a high vacuum to reduce residual gases, the alloy acts as a "getter," rapidly absorbing oxygen and nitrogen, which leads to immediate oxidation and severe degradation of the material's properties.

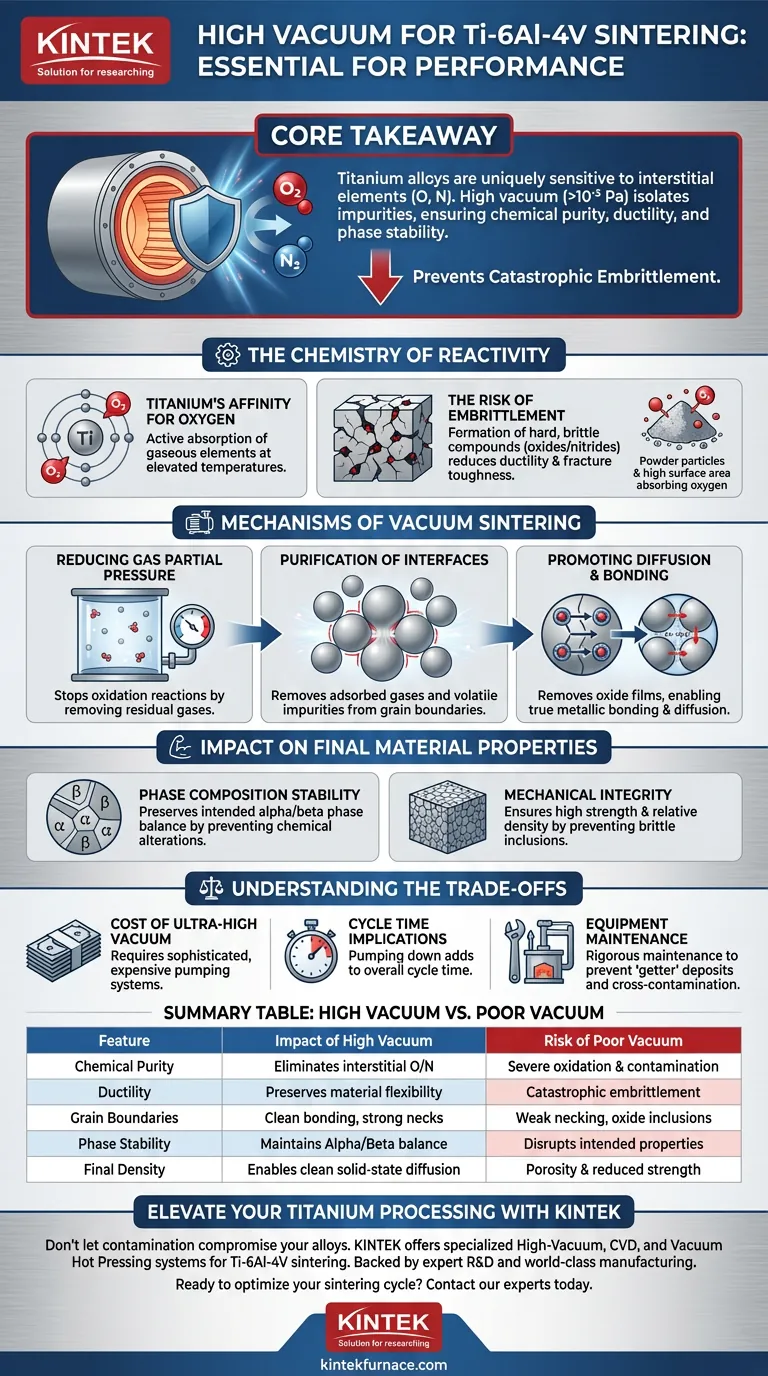

Core Takeaway Titanium alloys are uniquely sensitive to interstitial elements; even trace amounts of oxygen or nitrogen can cause catastrophic embrittlement. A high vacuum environment (often lower than $10^{-3}$ Pa) is the only reliable method to isolate these impurities, ensuring the chemical purity, ductility, and phase stability necessary for a high-performance sintered part.

The Chemistry of Reactivity

Titanium's Affinity for Oxygen

Titanium and aluminum (a key component of Ti-6Al-4V) possess an extremely high chemical affinity for oxygen. Upon heating, they do not just coat chemically; they actively absorb gaseous elements.

The Risk of Embrittlement

When these alloys absorb oxygen and nitrogen, hard, brittle compounds (oxides and nitrides) form within the material matrix. This process, known as embrittlement, drastically reduces ductility and fracture toughness.

Surface Area Sensitivity

This reactivity is amplified when working with powders. Fine titanium particles have a large specific surface area, making them even more sensitive to oxidation than bulk material.

Mechanisms of Vacuum Sintering

Reducing Gas Partial Pressure

A high vacuum furnace reduces the partial pressure of residual gases to negligible levels (e.g., $10^{-3}$ to $10^{-5}$ Pa). This effectively stops oxidation reactions before they can begin.

Purification of Interfaces

Vacuum environments facilitate the removal of adsorbed gases and volatile impurities from the surface of the powder particles. By cleaning these grain boundaries, the furnace prevents the formation of oxide inclusions that would otherwise weaken the structure.

Promoting Diffusion and Bonding

For sintering to occur, atoms must diffuse across particle boundaries to form "necks." Vacuum removes the oxide films that act as barriers to this diffusion. This ensures true metallic bonding and effective solid-state reactions.

Impact on Final Material Properties

Phase Composition Stability

The mechanical performance of Ti-6Al-4V relies on a specific balance of alpha and beta phases. High vacuum prevents chemical alterations that would disrupt this balance, ensuring the final alloy maintains its intended phase stability.

Mechanical Integrity

By preventing the inclusion of brittle oxides, the vacuum ensures the sintered body retains high mechanical strength and relative density. This is critical for preventing premature failure under stress.

Understanding the Trade-offs

The Cost of Ultra-High Vacuum

Achieving the necessary vacuum levels (such as $10^{-5}$ mbar or lower) requires sophisticated, expensive pumping systems. Any compromise in seal integrity or pump performance will result in a "scrap" batch due to immediate contamination.

Cycle Time Implications

Creating a high-purity vacuum environment takes time. The pumping down process adds to the overall cycle time compared to inert gas sintering, though the superior mechanical properties often justify this efficiency trade-off.

Equipment Maintenance

Vacuum furnaces processing titanium require rigorous maintenance. The "getter" effect of titanium can result in deposits inside the furnace, and heating elements must be kept free of carbon or oxygen sources to prevent cross-contamination.

Making the Right Choice for Your Goal

Achieving the optimal sintered Ti-6Al-4V part requires aligning your furnace capabilities with your specific mechanical requirements.

- If your primary focus is Maximum Ductility: Ensure your furnace can maintain a stable high vacuum (better than $10^{-4}$ Pa) throughout the holding phase to minimize interstitial embrittlement.

- If your primary focus is High Density: Consider a Vacuum Hot Pressing furnace, which combines high vacuum with mechanical pressure (e.g., 50 MPa) to force particle contact and accelerate densification.

- If your primary focus is Microstructure Control: Prioritize vacuum systems that offer precise temperature control alongside impurity isolation to prevent excessive grain growth while purifying grain boundaries.

The vacuum level is not merely an operational setting; it is the defining variable that dictates whether you produce a high-performance alloy or a brittle, unusable component.

Summary Table:

| Feature | Impact of High Vacuum | Risk of Poor Vacuum |

|---|---|---|

| Chemical Purity | Eliminates interstitial oxygen/nitrogen | Severe oxidation and "getter" contamination |

| Ductility | Preserves material flexibility | Catastrophic embrittlement and brittleness |

| Grain Boundaries | Removes oxide films for better bonding | Weak necking and oxide inclusions |

| Phase Stability | Maintains Alpha/Beta phase balance | Disrupts intended microstructural properties |

| Final Density | Enables clean solid-state diffusion | Porosity and reduced mechanical strength |

Elevate Your Titanium Processing with KINTEK

Don't let contamination compromise your high-performance alloys. Backed by expert R&D and world-class manufacturing, KINTEK offers specialized High-Vacuum, CVD, and Vacuum Hot Pressing systems specifically designed for the rigorous demands of Ti-6Al-4V sintering. Our customizable laboratory and industrial high-temperature furnaces ensure the precise atmosphere control needed to prevent embrittlement and maximize material density.

Ready to optimize your sintering cycle? Contact our experts today to find the perfect vacuum solution for your unique needs.

Visual Guide

References

- Yujin Yang. Optimization of large cast Haynes 282 based on thermal induced cracks: formation and elimination. DOI: 10.1051/meca/2024008

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What environmental controls does a vacuum diffusion furnace provide? Master High-Vacuum Heat Treatment

- How energy efficient are vacuum annealing furnaces? Save 20-30% on energy costs with advanced heating.

- What is the importance of vacuum furnaces in energy and power generation? Boost Efficiency and Reliability

- What are the main advantages of multi-chamber vacuum furnaces? Boost Efficiency and Cut Costs

- Why is repeated flipping and remelting necessary in vacuum arc melting? Ensure HEA Chemical Homogeneity

- Why are vacuum-melted materials preferred for medical implants? Ensure Implant Purity and Longevity

- What is the necessity of using a vacuum drying oven for Al2O3-TiC? Ensure Purity & Prevent Oxidation

- What role do laboratory high-temperature furnaces play in the growth of Ni3In2Se2 single crystals? Precision Growth Control