At its core, vacuum-melted materials are preferred for medical implants because the process removes detrimental impurities and dissolved gases that are unavoidable in standard air-melting techniques. This creates an exceptionally pure, strong, and biocompatible material that significantly reduces the risk of implant failure and adverse reactions within the human body.

The fundamental challenge is that reactive metals like titanium and specialty steels act as sponges for atmospheric gases when molten. Vacuum melting is not merely a preference but a necessary manufacturing control to produce a material clean enough and strong enough to be trusted inside a human being for decades.

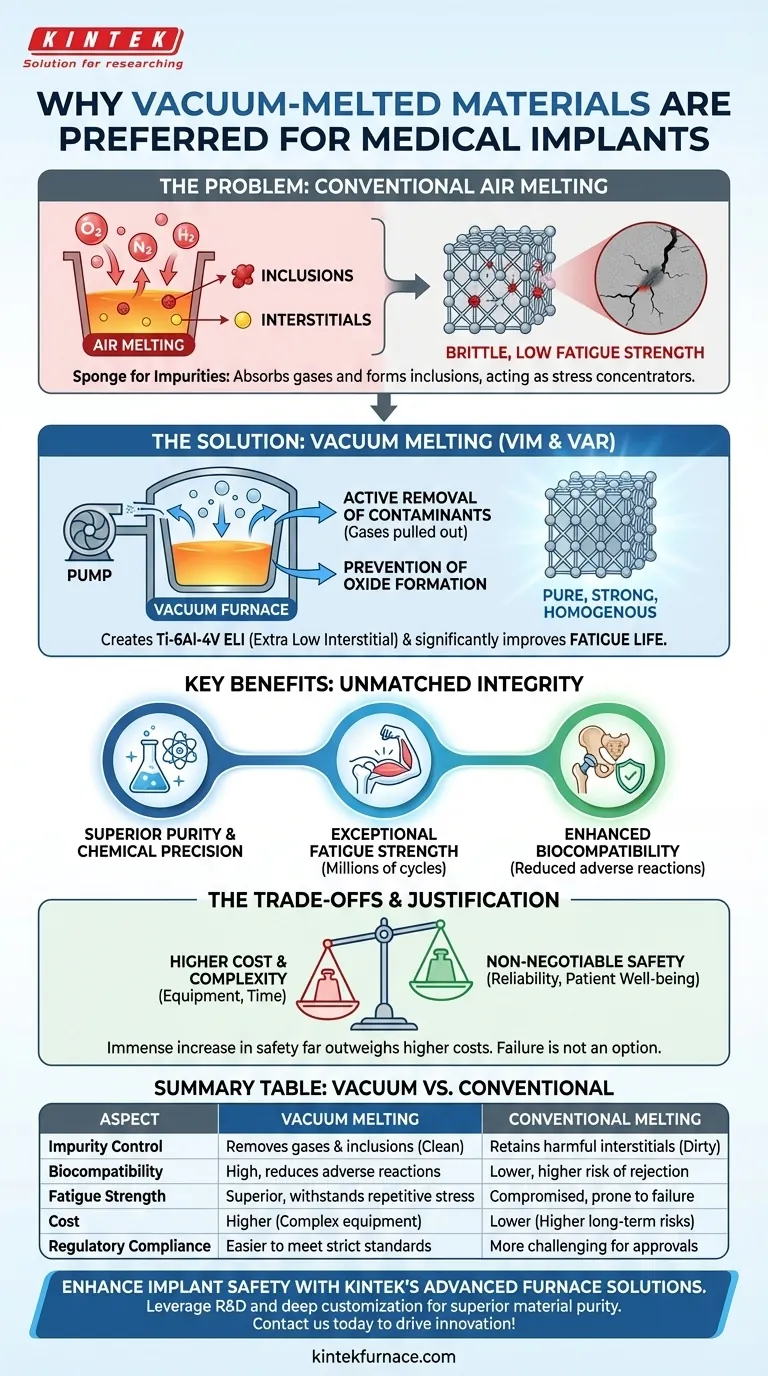

The Problem with Conventional Melting

To understand the value of vacuum melting, we must first recognize the inherent flaws of melting metals in the open air. The atmosphere, which is rich in oxygen and nitrogen, is highly reactive with molten metal.

The Threat of Gaseous Impurities

When metals like titanium or stainless steel are melted, they readily absorb oxygen, nitrogen, and hydrogen from the air and moisture. These dissolved gases become trapped within the metal's crystal structure as it cools.

These trapped elements, known as interstitials, disrupt the atomic lattice. This disruption makes the final material more brittle and severely compromises its ability to withstand repetitive stress, a property known as fatigue strength.

The Danger of Inclusions

Reactions between the molten metal and the atmosphere (or the crucible) also form tiny, hard, ceramic-like particles called non-metallic inclusions. These are microscopic impurities, such as oxides and nitrides, suspended within the metal.

Each inclusion acts as a stress concentrator. Under load, the stress in the implant will focus on these points, creating a microscopic crack that can grow over time and lead to catastrophic fatigue failure. For a hip or knee implant expected to endure millions of cycles, this is an unacceptable risk.

How Vacuum Melting Delivers a Superior Material

Vacuum melting processes, such as Vacuum Induction Melting (VIM) and Vacuum Arc Remelting (VAR), directly counteract these issues by controlling the manufacturing environment. The entire process is conducted under a powerful vacuum.

Active Removal of Contaminants

The low-pressure environment of a vacuum furnace has a powerful cleansing effect. Dissolved gases like hydrogen and nitrogen, which are detrimental to mechanical properties, are literally pulled out of the molten metal bath.

This purification process is what creates grades of material like Ti-6Al-4V ELI (Extra Low Interstitial). The "ELI" designation is a direct result of vacuum melting reducing the oxygen content to improve the alloy's fracture toughness and fatigue resistance.

Prevention of Oxide Formation

By removing virtually all the oxygen from the environment, vacuum melting prevents the formation of the harmful oxide inclusions that plague air-melted materials. This results in a much "cleaner" and more homogenous metal at the microscopic level.

Fewer inclusions mean fewer internal points for cracks to start. This directly translates to a massive improvement in fatigue life and overall material reliability, ensuring the implant can withstand the rigors of daily human activity.

Unmatched Chemical Precision

The controlled vacuum environment also allows for extremely precise control over the alloy's final chemistry. Alloying elements can be added in exact amounts without the risk of them being lost to oxidation.

This ensures that every batch of material meets the strict chemical specifications required for medical devices, providing the lot-to-lot consistency demanded by regulatory bodies like the FDA.

Understanding the Trade-offs

While the benefits are clear, it is important to recognize that vacuum melting is not a universal solution for all metal products. The choice to use it is a calculated one based on risk and requirement.

Increased Cost and Complexity

Vacuum furnaces are complex, expensive pieces of equipment to build, operate, and maintain. The entire process is more technically demanding than standard air melting.

This higher operational cost translates directly to a higher material cost. Vacuum-melted alloys are significantly more expensive than their air-melted counterparts.

Longer Processing Cycles

Achieving and maintaining a high vacuum, carefully controlling the melt, and allowing for degassing all take time. A vacuum melting cycle is considerably longer than a simple air melt.

This reduces throughput and adds to the lead time for producing the raw material, which can impact project timelines.

The Justification: Safety is Non-Negotiable

For medical implants, the trade-off is simple. The immense increase in safety, reliability, and biocompatibility provided by vacuum-melted materials far outweighs the higher cost and longer processing time. The potential cost of an implant failure—in terms of patient suffering and subsequent revision surgeries—is incalculable.

Applying This to Your Material Selection

Your choice of material processing must be directly tied to the application's risk profile and performance requirements.

- If your primary focus is critical, long-term implants (e.g., hip stems, spinal cages, pacemakers): Vacuum-melted and remelted materials are the only acceptable choice to ensure maximum fatigue life and biocompatibility.

- If your primary focus is on external or temporary devices (e.g., surgical instruments, bone screws): High-quality air-melted materials may be sufficient, but a thorough risk analysis is still required.

- If your primary focus is regulatory approval and risk mitigation: The purity, consistency, and traceability offered by vacuum melting provide the robust documentation needed to satisfy regulatory bodies.

Ultimately, the integrity of a medical implant begins with the absolute purity of its raw material.

Summary Table:

| Aspect | Vacuum Melting | Conventional Melting |

|---|---|---|

| Impurity Control | Removes gases and inclusions | Retains harmful interstitials |

| Biocompatibility | High, reduces adverse reactions | Lower, higher risk of rejection |

| Fatigue Strength | Superior, withstands repetitive stress | Compromised, prone to failure |

| Cost | Higher due to complex equipment | Lower, but higher long-term risks |

| Regulatory Compliance | Easier to meet strict standards | More challenging for approvals |

Enhance your medical implant safety and performance with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, helping you achieve superior material purity and regulatory compliance. Contact us today to discuss how we can support your critical applications and drive innovation in medical device development!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Induction Melting Furnace

People Also Ask

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance