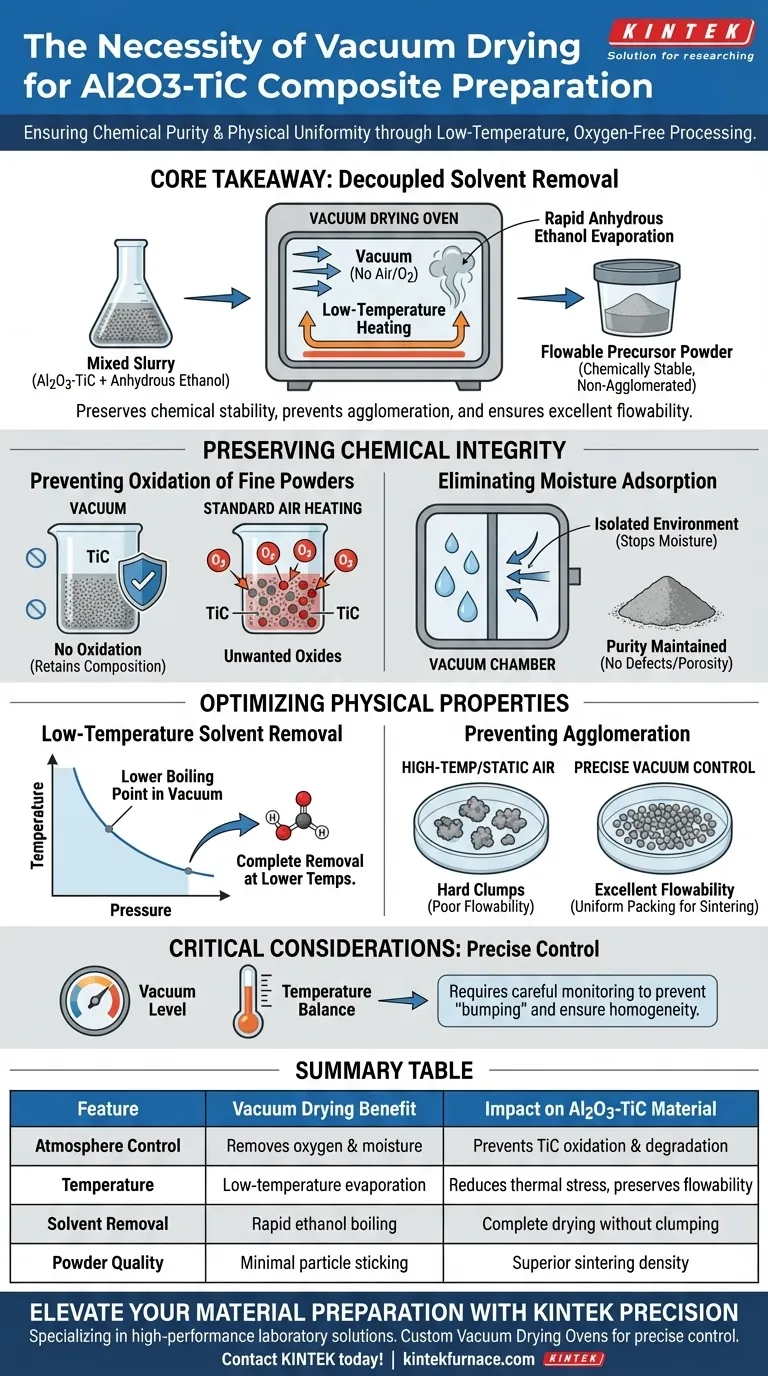

The use of a vacuum drying oven is a critical requirement in the preparation of Al2O3-TiC composite materials to ensure both chemical purity and physical uniformity. Its primary function is to completely remove anhydrous ethanol from the mixed slurry within a low-temperature environment, eliminating the risks associated with conventional heating methods.

Core Takeaway A vacuum drying oven decouples solvent removal from high heat, allowing anhydrous ethanol to evaporate rapidly without exposing the material to thermal stress or atmospheric oxygen. This preserves the chemical stability of the fine powders and prevents agglomeration, ensuring the precursor material has excellent flowability for subsequent processing.

Preserving Chemical Integrity

Preventing Oxidation of Fine Powders

The most significant danger during the drying phase of Al2O3-TiC preparation is oxidation. Titanium Carbide (TiC) and fine metallic powders are highly susceptible to reacting with oxygen, especially when heated.

By operating in a vacuum, the oven removes air from the chamber. This eliminates the presence of oxygen during the heating process, ensuring that the fine powders retain their intended chemical composition rather than converting into unwanted oxides.

Eliminating Moisture Adsorption

Standard atmospheric drying can leave materials vulnerable to ambient humidity.

A vacuum drying oven creates an isolated environment that stops moisture from adsorbing onto the powder surfaces. This is vital for maintaining the purity of the precursor powder, as adsorbed moisture can lead to defects or porosity in the final composite material.

Optimizing Physical Properties

Low-Temperature Solvent Removal

The preparation process involves a mixed slurry containing anhydrous ethanol.

A vacuum environment significantly lowers the boiling point of solvents. This allows the ethanol to be removed completely at much lower temperatures than would be required at standard atmospheric pressure.

Preventing Agglomeration

Drying at high temperatures or in static air often causes nanoparticles to stick together, forming hard clumps.

Precise vacuum control ensures the powder dries thoroughly without hard agglomeration. The result is a precursor powder with excellent flowability, which is essential for uniform packing and density during the subsequent shaping and sintering stages.

Critical Considerations and Trade-offs

The Necessity of Precise Control

While vacuum drying offers superior protection, it requires precise vacuum control to be effective.

Fluctuations in pressure can lead to uneven drying rates or incomplete solvent removal. Unlike simple convection ovens, a vacuum drying system demands careful monitoring to ensure the balance between temperature and pressure is maintained exactly right to prevent "bumping" (violent boiling) of the solvent, which could disrupt the homogeneity of the mixture.

Making the Right Choice for Your Goal

To maximize the quality of your Al2O3-TiC composites, align your drying strategy with your specific processing needs:

- If your primary focus is Chemical Purity: Prioritize the vacuum level to ensure absolute exclusion of oxygen, preventing the surface degradation of sensitive TiC particles.

- If your primary focus is Powder Processability: Focus on the temperature-pressure balance to ensure a gentle evaporation rate, which yields a loose, flowable powder that is easy to mold.

By controlling the atmosphere and temperature simultaneously, you transform a volatile slurry into a stable, high-quality precursor ready for sintering.

Summary Table:

| Feature | Vacuum Drying Benefit | Impact on Al2O3-TiC Material |

|---|---|---|

| Atmosphere Control | Removes oxygen & moisture | Prevents TiC oxidation and chemical degradation |

| Temperature | Low-temperature evaporation | Reduces thermal stress and preserves powder flowability |

| Solvent Removal | Rapid anhydrous ethanol boiling | Ensures complete drying without "bumping" or clumping |

| Powder Quality | Minimal particle sticking | Prevents agglomeration for superior sintering density |

Elevate Your Material Preparation with KINTEK Precision

Don’t compromise the integrity of your Al2O3-TiC composites with suboptimal drying. At KINTEK, we specialize in high-performance laboratory solutions backed by expert R&D and manufacturing. Our customizable Vacuum Drying Ovens, along with our specialized Muffle, Tube, Rotary, and CVD systems, are engineered to provide the precise temperature and atmosphere control required for sensitive lab high-temp processes.

Ready to achieve superior chemical purity and powder flowability?

Contact KINTEK today to discuss your unique laboratory needs!

Visual Guide

References

- Zara Cherkezova‐Zheleva, Radu Robert Piticescu. Green and Sustainable Rare Earth Element Recycling and Reuse from End-of-Life Permanent Magnets. DOI: 10.3390/met14060658

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Is vacuum brazing better than brazing? Unlock Superior Joint Quality for Critical Applications

- What role do high-temperature furnaces play in Ti-15Mo heat treatment? Unlock Advanced Alloy Performance

- What is the working principle of a vacuum heat treatment furnace? Achieve Clean, High-Integrity Metal Parts

- What are the limitations of high vacuum furnaces? Understand Costs, Time, and Material Challenges

- Why are vacuum furnaces indispensable in modern manufacturing? Achieve Superior Material Purity and Performance

- What are the primary applications of vacuum furnaces? Achieve High-Purity Heat Treatment for Aerospace and Medical

- How does a circulating water cooling system contribute to the stable operation of high-temp vacuum furnaces? | KINTEK

- Why is the use of a vacuum drying oven critical during LSC oxygen electrode modification? Achieve Deep Impregnation