In practice, vacuum brazing is not a competitor to brazing, but rather an advanced method of brazing. It offers exceptionally clean, strong, and flux-free joints by performing the process in a vacuum. This controlled environment prevents the formation of oxides that can compromise the joint's integrity, making it the superior choice for high-performance and mission-critical applications.

The core decision is not whether vacuum brazing is "better," but whether its superior results justify its higher cost and slower cycle times for your specific application. It trades raw speed for unparalleled quality and reliability.

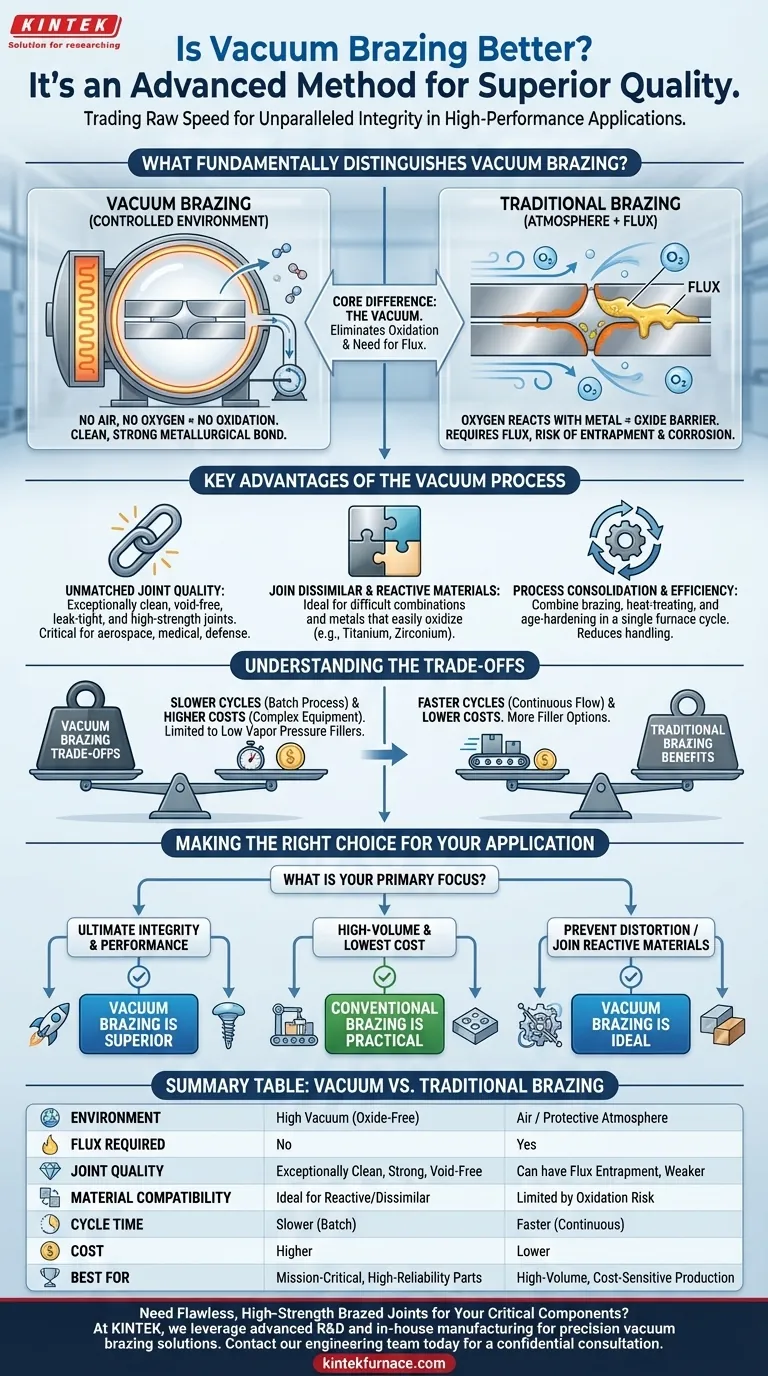

What Fundamentally Distinguishes Vacuum Brazing?

Vacuum brazing is a process where components are joined using a filler metal in a furnace chamber with the air pumped out. This fundamental difference from traditional atmospheric or torch brazing drives all of its unique characteristics.

The Role of the Vacuum: Preventing Oxidation

In a normal atmosphere, heating metals causes them to react with oxygen, forming oxides on the surface. These oxide layers act as a barrier, preventing the brazing filler metal from properly wetting and bonding with the parent materials.

A vacuum environment removes the oxygen. By eliminating the primary cause of oxidation, the filler metal can flow cleanly and create a direct, powerful metallurgical bond with the base metals.

Eliminating the Need for Flux

Traditional brazing methods rely on a chemical agent called flux. Flux acts as a cleaning agent, dissolving oxides and protecting the joint area from re-oxidation during heating.

Because vacuum brazing prevents oxides from forming in the first place, flux is entirely unnecessary. This is a significant advantage, as it eliminates the risk of flux becoming trapped in the joint, which can cause corrosion and create a point of weakness over time. It also saves the cost and labor of post-braze cleaning.

Precise Thermal Control

Vacuum furnaces offer extremely uniform and precisely controlled heating and cooling cycles. The entire assembly is brought to temperature slowly and evenly, and cooled in a similarly controlled manner.

This gentle thermal cycling minimizes residual stress and distortion in the finished part. This is critical for complex, precision-engineered components that must maintain their exact shape and dimensional stability.

The Key Advantages of the Vacuum Process

The unique environment of a vacuum furnace produces a set of distinct and powerful benefits that are difficult to achieve with other methods.

Unmatched Joint Quality and Strength

By eliminating oxides and the potential for flux entrapment, vacuum brazing creates joints that are exceptionally clean, strong, and free of voids. This leads to superior performance, leak-tight seals, and high reliability, which are essential in industries like aerospace, medical, and defense.

Joining Dissimilar and Reactive Materials

The controlled, inert environment is ideal for joining materials that are difficult to connect otherwise. This includes joining metals to ceramics or joining reactive metals like titanium and zirconium, which would oxidize instantly in a normal atmosphere.

Process Consolidation and Efficiency

A single cycle in a vacuum furnace can combine multiple processes. For example, a part can be brazed, heat-treated, and age-hardened all in one run without ever leaving the furnace.

While the furnace cycle itself might be long, this consolidation can save significant time and handling, making it highly efficient for complex parts that would otherwise require multiple separate manufacturing steps.

Understanding the Trade-offs

No process is superior in all situations. The benefits of vacuum brazing come with clear and important trade-offs.

Slower Production Cycle Times

Vacuum brazing is a batch process. Parts must be loaded into the furnace, a vacuum must be drawn, and the heating and cooling cycles can take several hours. This is inherently slower than continuous or single-piece flow methods like torch or induction brazing.

Higher Equipment and Operational Costs

Vacuum furnaces represent a significant capital investment. They are complex machines that require specialized knowledge to operate and maintain, leading to higher operational costs compared to simpler brazing setups.

Not Suitable for All Filler Metals

Some brazing filler metals have high vapor pressures (e.g., those containing zinc or cadmium). When heated in a vacuum, these elements can "boil off," altering the filler metal's composition and potentially contaminating the furnace. This limits the choice of filler materials to those with low vapor pressures.

Making the Right Choice for Your Application

The decision to use vacuum brazing depends entirely on your project's priorities. Weigh the need for ultimate quality against the constraints of cost and speed.

- If your primary focus is ultimate joint integrity and performance: For applications in aerospace, medical devices, or high-performance engines where failure is not an option, vacuum brazing is the superior choice.

- If your primary focus is high-volume production of simple parts at the lowest cost: Conventional methods like torch, induction, or furnace brazing with flux or a protective atmosphere are far more practical and economical.

- If your primary focus is preventing part distortion or joining reactive materials: The precise thermal control and inert environment of vacuum brazing make it the ideal solution.

Choosing the right joining method requires you to match the process capabilities to your engineering goals.

Summary Table:

| Aspect | Vacuum Brazing | Traditional Brazing |

|---|---|---|

| Environment | High vacuum (prevents oxidation) | Air or protective atmosphere |

| Flux Required | No | Yes |

| Joint Quality | Exceptionally clean, strong, void-free | Can have flux entrapment, weaker |

| Material Compatibility | Ideal for reactive/dissimilar metals | Limited by oxidation risk |

| Cycle Time | Slower (batch process) | Faster (continuous/single-piece) |

| Cost | Higher equipment/operational cost | Lower initial cost |

| Best For | Mission-critical, high-reliability parts | High-volume, cost-sensitive production |

Need Flawless, High-Strength Brazed Joints for Your Critical Components?

At KINTEK, we leverage our advanced R&D and in-house manufacturing to deliver precision vacuum brazing solutions tailored to your most demanding applications. Our expertise ensures:

- Oxide-Free, Metallurgically Perfect Joints for aerospace, medical, and defense components

- Flux-Free Process eliminating corrosion risks and post-braze cleaning

- Precision Thermal Control minimizing distortion in complex, delicate parts

- Deep Customization of our vacuum furnace systems to meet your exact material and geometry requirements

Let's discuss how our vacuum brazing expertise can enhance your product's reliability and performance. Contact our engineering team today for a confidential consultation.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion