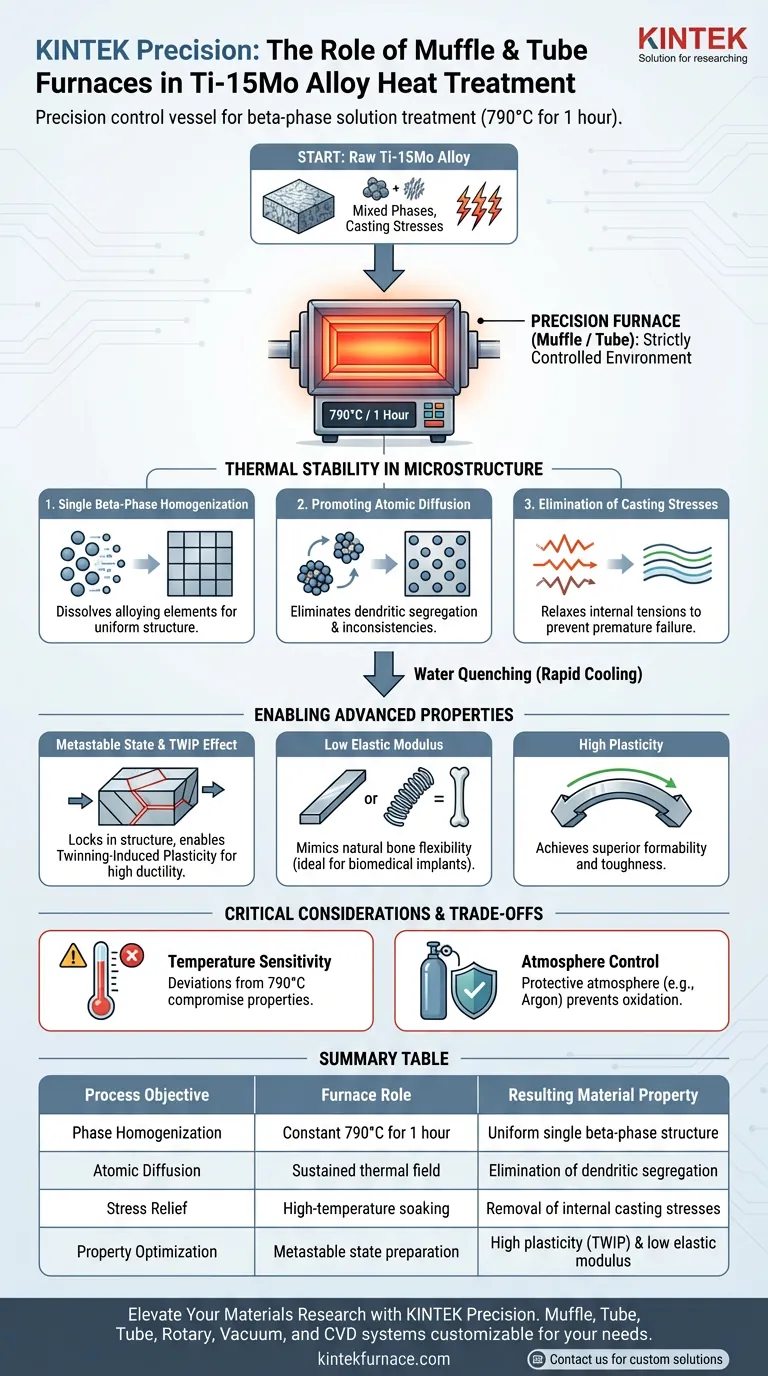

High-temperature Muffle or Tube furnaces act as the precision control vessel necessary for the beta-phase solution treatment of Ti-15Mo alloys. Specifically, these furnaces are used to maintain the alloy at a constant temperature of 790°C for a duration of one hour. This strictly controlled environment is the prerequisite for homogenizing the microstructure, eliminating casting stresses, and achieving a single beta-phase structure prior to quenching.

The core function of this heat treatment is to establish a stable thermodynamic state where the alloy achieves a uniform single beta-phase. This specific microstructural configuration is the critical foundation for inducing the Twinning-Induced Plasticity (TWIP) effect and achieving a low elastic modulus in the final material.

The Role of Thermal Stability in Microstructure

Achieving Single Beta-Phase Homogenization

The primary objective of using these furnaces is to hold the Ti-15Mo alloy at exactly 790°C. At this specific temperature, the furnace environment allows for the complete dissolution of alloying elements into the titanium matrix. This results in a uniform, single beta-phase structure, which is distinct from the mixed phases present after initial casting.

Promoting Atomic Diffusion

The stable thermal field provided by Muffle or Tube furnaces drives atomic diffusion. This mechanism is essential for eliminating dendritic segregation—chemical inconsistencies that form during the solidification process. By maintaining a constant temperature for one hour, the furnace allows the alloy to reach a thermodynamic equilibrium, ensuring the element distribution is consistent throughout the material.

Elimination of Casting Stresses

Beyond phase transformation, the furnace plays a vital role in stress relief. The sustained high temperature relaxes the internal tensions known as casting stresses. Removing these stresses is necessary to prevent premature failure and to ensure the material behaves predictably during subsequent processing steps.

Enabling Advanced Mechanical Properties

Creating the Metastable State

The furnace treatment is not the final step; it is the preparation for water quenching. By achieving a perfect single beta-phase at high temperatures, the subsequent rapid cooling locks the microstructure into a "metastable" beta state. It is this specific metastable condition that grants the alloy its high plasticity.

Facilitating the TWIP Effect

The precise heat treatment regimen is directly responsible for enabling the Twinning-Induced Plasticity (TWIP) effect. The furnace ensures the microstructure is tuned to the exact stability required to trigger mechanical twinning during deformation, which significantly enhances the material's ductility.

Lowering the Elastic Modulus

For applications requiring flexibility (such as biomedical implants), the furnace process is crucial. The resulting metastable beta microstructure exhibits a low elastic modulus. This property allows the material to mimic natural bone flexibility more closely than other titanium phases.

Understanding the Trade-offs

Sensitivity to Temperature Deviations

While these furnaces are powerful, the process is intolerant of error. Phase transformations in titanium alloys are extremely sensitive to temperature fluctuations. A deviation from the 790°C target can lead to incomplete phase transformation or unintended grain coarsening, which would compromise the mechanical properties.

The Necessity of Atmosphere Control

High-temperature treatment requires a stable environment to prevent degradation. While the heat drives diffusion, it must often be coupled with a protective atmosphere (such as the low-flow argon mentioned in supplementary contexts for similar alloys) to prevent oxidation. Without this stability, the purity and surface quality of the Ti-15Mo alloy cannot be guaranteed.

Making the Right Choice for Your Goal

To maximize the effectiveness of heat treatment for Ti-15Mo, align your process controls with your specific material objectives:

- If your primary focus is maximizing ductility (TWIP effect): Ensure your furnace maintains 790°C with high precision to guarantee the formation of the specific metastable beta phase required for twinning.

- If your primary focus is structural integrity: Prioritize the one-hour holding time to ensure sufficient atomic diffusion for the complete elimination of casting stresses and segregation.

Precision in the furnace chamber is the defining factor between a standard alloy and a high-performance material.

Summary Table:

| Process Objective | Furnace Role | Resulting Material Property |

|---|---|---|

| Phase Homogenization | Constant 790°C for 1 hour | Uniform single beta-phase structure |

| Atomic Diffusion | Sustained thermal field | Elimination of dendritic segregation |

| Stress Relief | High-temperature soaking | Removal of internal casting stresses |

| Property Optimization | Metastable state preparation | High plasticity (TWIP) & low elastic modulus |

Elevate Your Materials Research with KINTEK Precision

Precise heat treatment is the difference between standard titanium and high-performance alloys. At KINTEK, we provide the specialized equipment necessary to achieve the exact thermal stability required for Ti-15Mo and other advanced materials.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your unique laboratory or industrial needs. Whether you are aiming to trigger the TWIP effect or optimize microstructural homogenization, our high-temp furnaces deliver the accuracy your research demands.

Ready to refine your thermal processes? Contact us today to find your custom furnace solution.

Visual Guide

References

- Tiewei Xu, Bin-Jiang Lv. The {332}<113> Twinning Behavior of a Ti-15Mo Medical Alloy during Cyclic Deformation and Its Effect on Microstructure and Performance. DOI: 10.3390/ma17071462

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- How does a high-temperature muffle furnace contribute to the thermal treatment process of chalcopyrite ore?

- How is an industrial-grade ashing furnace utilized in 3D-printed bioactive glass? Master Debinding & Sintering

- How does high-temperature heating facilitate the conversion of rice husks into inorganic precursors for silica extraction?

- How is the thermal stability of KBaBi compounds evaluated? Discover Precise XRD & Heat Treatment Limits