In modern manufacturing, vacuum furnaces are indispensable because they provide an exceptionally clean and controlled environment for high-temperature material processing. By removing the atmosphere, these furnaces prevent oxidation and contamination, which allows for the creation of components with superior strength, purity, and performance that are simply unattainable with conventional methods.

The core value of a vacuum furnace is not the vacuum itself, but the perfect control it provides. By eliminating reactive gases like oxygen, manufacturers can manipulate materials at a chemical level, ensuring the final product meets the most demanding specifications without degradation.

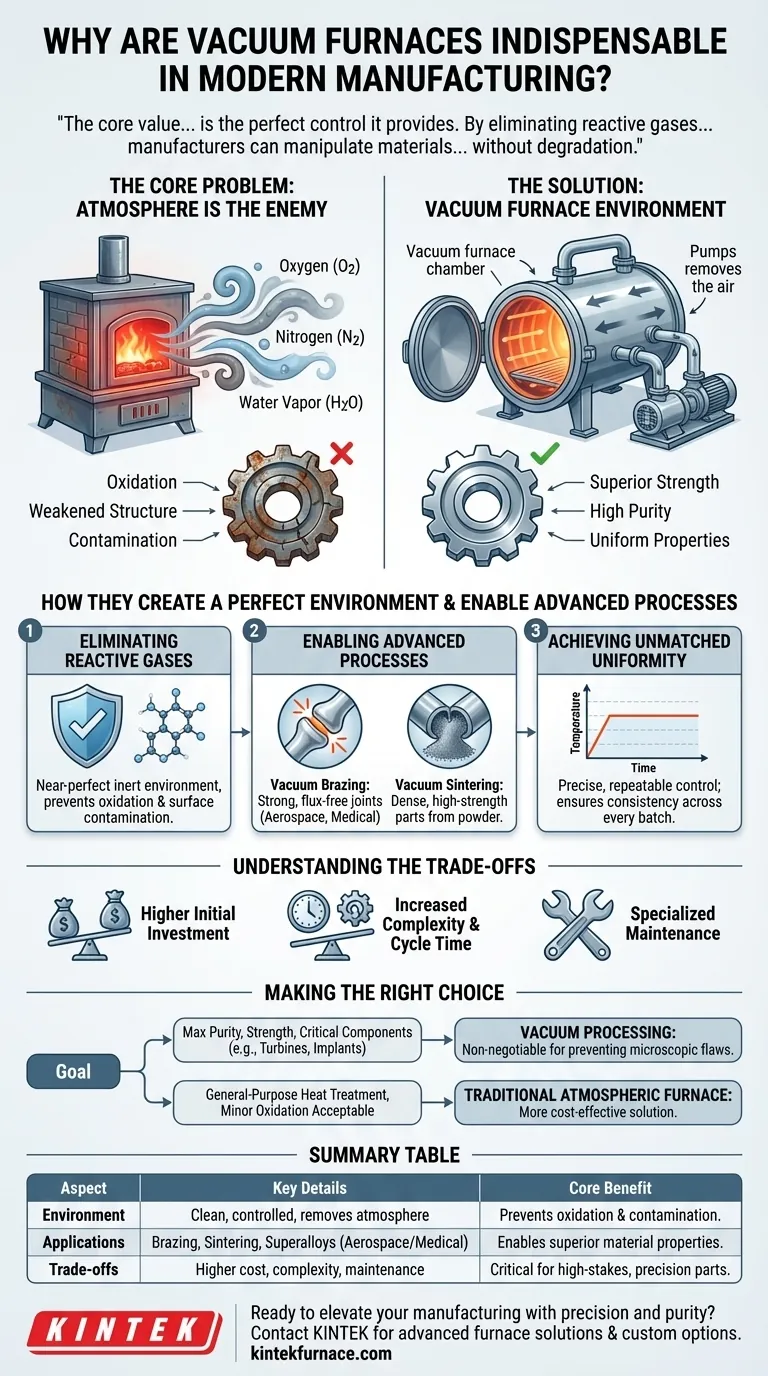

The Core Problem: Why Atmosphere is the Enemy of High-Temperature Processing

To understand the value of a vacuum, we must first recognize the problem it solves. At high temperatures, the air we breathe becomes a significant source of contamination for most metals and alloys.

The Threat of Oxidation and Contamination

When heated, materials become highly reactive. The oxygen, nitrogen, and water vapor present in a normal atmosphere will react with the surface of a part.

This leads to oxidation (like rust), decarburization (loss of carbon, which weakens steel), and the formation of other undesirable surface layers that compromise the material's mechanical properties and integrity.

The Limitations of Traditional Furnaces

Conventional furnaces that operate in a normal atmosphere cannot prevent these reactions. While some use inert "purge" gases to displace oxygen, this method is often imperfect and cannot achieve the level of purity required for critical applications.

Any residual reactive gas can still cause microscopic flaws that become major failure points in a high-performance component.

How Vacuum Furnaces Create a Perfect Processing Environment

A vacuum furnace works by pumping nearly all the air out of a sealed chamber before heating begins. This fundamental difference unlocks several key advantages.

Eliminating Reactive Gases

The primary benefit is creating a near-perfectly inert environment. With no oxygen or water vapor to react with, materials can be heated to extreme temperatures without fear of oxidation or surface contamination.

This preserves the base material's chemistry, ensuring its properties—like hardness, tensile strength, and fatigue resistance—are fully realized.

Enabling Advanced Processes

This pristine environment is a prerequisite for sophisticated manufacturing techniques. Processes like high-temperature brazing, sintering, and the creation of superalloys depend on it.

Vacuum brazing, for example, creates incredibly strong and clean joints between parts without using corrosive flux, which is essential for aerospace and medical devices. Vacuum sintering fuses powdered metals into dense, high-strength parts that are impossible to make otherwise.

Achieving Unmatched Uniformity and Control

Modern vacuum furnaces offer exceptional temperature uniformity and precise, repeatable control over heating and cooling cycles.

This ensures that every part in a batch, and every batch over time, receives the exact same treatment. This consistency is critical in industries like aerospace and healthcare, where even minor deviations are unacceptable.

Understanding the Trade-offs

While powerful, vacuum furnaces are not the solution for every application. Their benefits come with clear and important trade-offs.

Higher Initial Investment

Vacuum furnaces are complex systems with sophisticated pumps, controls, and chamber construction. This results in a significantly higher initial capital cost compared to traditional atmospheric furnaces.

Increased Process Complexity and Cycle Time

Operating a vacuum furnace requires more technical expertise. The process of pumping down the chamber to the required vacuum level adds time to each cycle, which can impact overall throughput for high-volume production.

Maintenance Requirements

The high-vacuum pumps, seals, and instrumentation that make these furnaces effective also require diligent and specialized maintenance to ensure they operate correctly and prevent leaks.

Making the Right Choice for Your Application

The decision to use a vacuum furnace must be driven by the end-goal for the component being produced.

- If your primary focus is maximum material purity and strength (e.g., aerospace turbines, medical implants): Vacuum processing is non-negotiable, as it is the only way to prevent the microscopic flaws that can lead to catastrophic failure.

- If your primary focus is joining complex, critical components without contamination: Vacuum brazing is the superior method for creating strong, leak-proof, and flux-free joints.

- If your primary focus is general-purpose heat treatment where minor surface oxidation is acceptable: A traditional atmospheric furnace may be a more cost-effective solution.

Ultimately, mastering the controlled environment of a vacuum furnace is the key to unlocking the full potential of modern materials.

Summary Table:

| Aspect | Key Details |

|---|---|

| Core Benefit | Provides a clean, controlled environment to prevent oxidation and contamination, enabling superior material strength and purity. |

| Key Applications | High-temperature brazing, sintering, superalloy production for aerospace, medical devices, and critical components. |

| Trade-offs | Higher initial cost, increased process complexity and cycle time, and specialized maintenance requirements. |

| Ideal Use Cases | Essential for maximum purity and strength (e.g., turbines, implants), non-contaminating brazing; not for general heat treatment with acceptable oxidation. |

Ready to elevate your manufacturing with precision and purity? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our vacuum furnaces can enhance your material processing and deliver unmatched performance for your critical applications!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties