At its core, a vacuum furnace is a tool for achieving material purity and precision. While it performs many functions, its primary applications are heat treatment, brazing, and sintering. These processes are used across industries like aerospace, medical, and electronics to create components with superior strength, cleanliness, and specific metallurgical properties that are impossible to achieve in a standard atmospheric environment.

A vacuum furnace's primary function is not just to heat materials, but to do so in an environment free of oxygen and other contaminants. This prevention of unwanted chemical reactions, like oxidation, is what enables the high-strength, high-purity results required by industries from aerospace to medical devices.

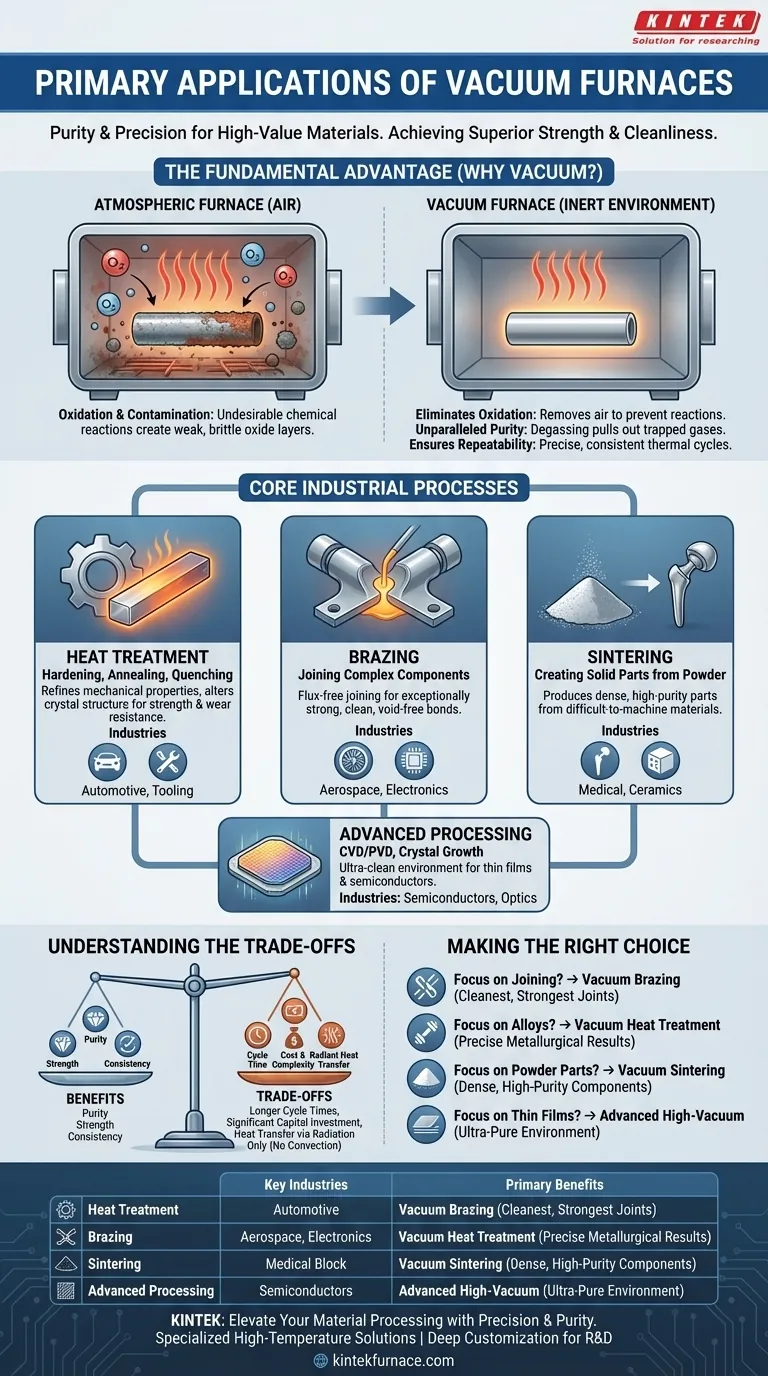

The Fundamental Advantage: Why Use a Vacuum?

To understand the applications of a vacuum furnace, you must first understand the problem it solves. Heating materials, especially metals, in the presence of air causes undesirable chemical reactions. A vacuum provides a controlled, inert environment.

Eliminating Oxidation and Contamination

At high temperatures, most metals readily react with oxygen in the air, forming a weak, brittle oxide layer on the surface. A vacuum furnace removes the oxygen, preventing this reaction and preserving the material's surface finish and structural integrity.

Achieving Unparalleled Purity

The vacuum actively pulls out trapped gases and volatile elements from within the material itself, a process known as degassing. This results in a purer, denser final product with improved mechanical and electrical properties.

Ensuring Process Repeatability

By removing the variable of atmospheric composition, a vacuum furnace allows for precise control over the entire thermal cycle. This ensures that every part processed receives the exact same treatment, leading to highly consistent and repeatable outcomes.

Core Industrial Processes and Their Applications

The controlled environment of a vacuum furnace enables several critical manufacturing processes that are defined by their need for cleanliness and precision.

Heat Treatment (Hardening, Annealing, and Quenching)

Heat treatment alters the microscopic crystal structure of a material to refine its mechanical properties.

Vacuum annealing softens metals to relieve internal stresses and improve ductility. Vacuum hardening and quenching create exceptionally hard and wear-resistant surfaces, essential for high-performance steel alloys used in the automotive and tool industries.

Brazing (Joining Complex Components)

Vacuum brazing joins two or more materials using a filler metal that has a lower melting point than the base materials.

The vacuum ensures the filler metal flows cleanly into the joint without the need for corrosive fluxes. This creates exceptionally strong, void-free bonds, critical for assembling sensitive components like aerospace turbine blades and vacuum interrupters for the electrical industry.

Sintering (Creating Solid Parts from Powder)

Sintering is the process of compacting and forming a solid mass of material from powder through heat, but without melting it to the point of liquefaction.

Vacuum sintering is vital for producing dense, high-purity parts from materials that are difficult to machine, such as ceramics, hard alloys (carbides), and biocompatible metals for medical implants. It is also a key post-processing step for metal 3D-printed parts.

Advanced Material Processing

The highest-purity applications rely exclusively on vacuum environments.

Processes like Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD) use a vacuum to deposit exceptionally thin films onto substrates for the semiconductor and optics industries. Similarly, growing large, single crystals for electronics requires the ultra-clean environment only a high-vacuum furnace can provide.

Understanding the Trade-offs

While powerful, vacuum furnaces are not a universal solution. Their benefits come with specific trade-offs that must be considered.

Cycle Time and Throughput

A significant portion of a vacuum furnace cycle is dedicated to pumping the chamber down to the required vacuum level and then carefully controlling the cooling rate. This results in longer cycle times compared to continuous atmospheric furnaces, making them less suitable for high-volume, low-margin production.

Cost and Complexity

Vacuum furnaces represent a significant capital investment. They require complex support systems, including vacuum pumps, cooling water circuits, and sophisticated control instrumentation. Operation and maintenance demand specialized training and expertise.

Heat Transfer Mechanism

In a vacuum, heat transfer occurs primarily through radiation, as there is no air to enable convection. While this provides excellent temperature uniformity for well-designed loads, it can pose challenges for heating thick parts or components with "shadowed" internal features that are not in the line of sight of the heating elements.

Making the Right Choice for Your Goal

Selecting a thermal process depends entirely on the required properties of your final product.

- If your primary focus is joining complex, high-value parts: Vacuum brazing provides the cleanest and strongest joints, free from the oxides and flux contamination inherent in other methods.

- If your primary focus is maximizing the mechanical properties of advanced alloys: Vacuum heat treatment is essential for preventing surface degradation and achieving precise, repeatable metallurgical results.

- If your primary focus is manufacturing dense, high-purity parts from powders: Vacuum sintering is the industry standard for creating components from ceramics, refractory metals, and materials for medical implants.

- If your primary focus is creating semiconductors or thin-film coatings: A high-vacuum furnace is non-negotiable for the ultra-pure environment these deposition and growth processes demand.

Ultimately, a vacuum furnace is the definitive choice when the chemical and structural integrity of the material cannot be compromised.

Summary Table:

| Application | Key Industries | Primary Benefits |

|---|---|---|

| Heat Treatment | Automotive, Tooling | Hardening, annealing, quenching for strength and wear resistance |

| Brazing | Aerospace, Electronics | Flux-free joining for strong, clean bonds |

| Sintering | Medical, Ceramics | Dense, high-purity parts from powders |

| Advanced Processing | Semiconductors, Optics | CVD/PVD for thin films and crystal growth |

Ready to elevate your material processing with precision and purity? KINTEK specializes in advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs in industries like aerospace, medical, and electronics. Contact us today to discuss how our vacuum furnaces can deliver superior results for your applications!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- What are the advantages of a vacuum hot pressing sintering furnace for rare earth copper composites? Density & Purity

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- How does pressure application in a vacuum hot press furnace facilitate sintering of copper composites? Optimize Density

- What role does a vacuum hot pressing furnace play in TiBw/TA15 synthesis? Enhance In-Situ Composite Performance