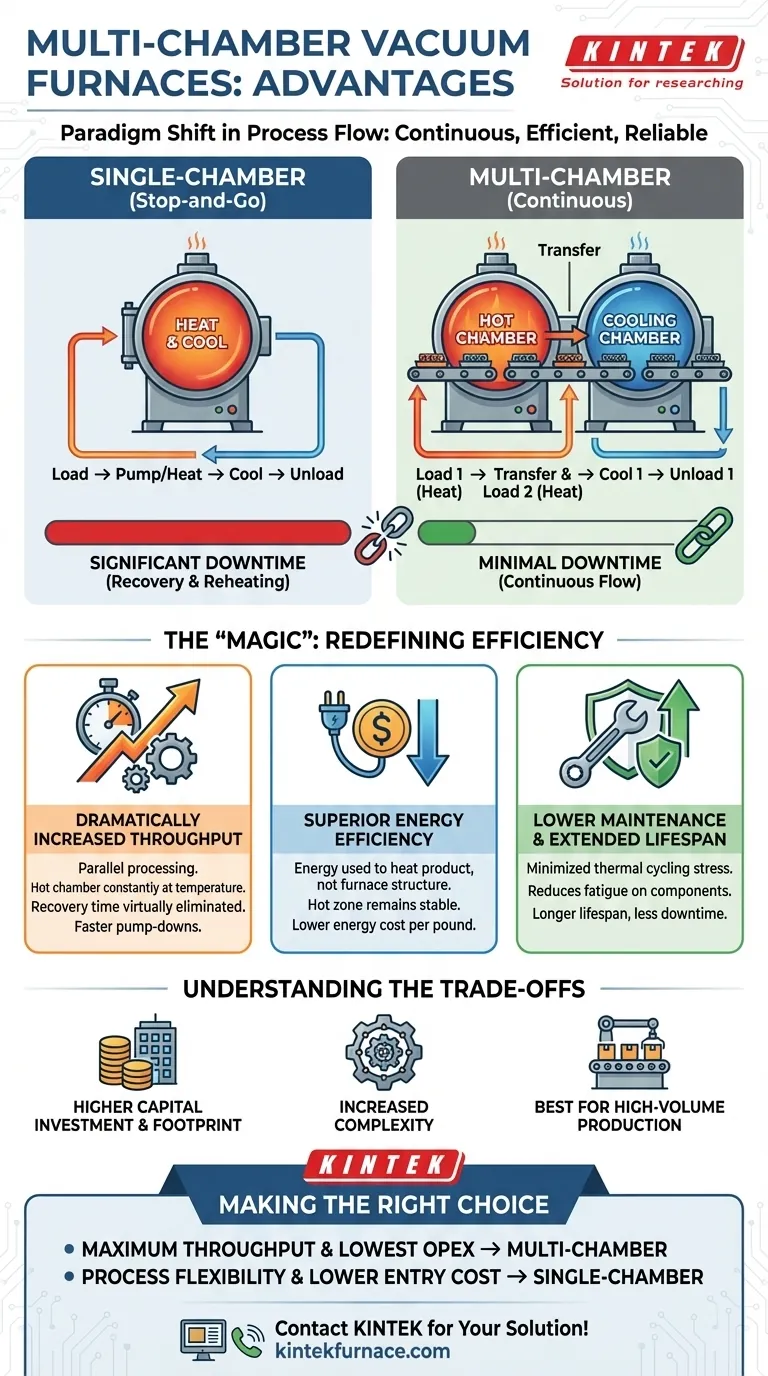

At their core, multi-chamber vacuum furnaces fundamentally solve the primary bottleneck of traditional single-chamber designs: the need to heat and cool the same chamber for every single load. By separating the heating and cooling processes into dedicated, specialized chambers, they enable a continuous workflow that dramatically increases throughput, improves energy efficiency, and reduces long-term maintenance costs.

The central advantage isn't just an incremental improvement; it's a paradigm shift in process flow. By moving from a batch process (heat, then cool) to a parallel one (heat one load while another cools), multi-chamber furnaces transform a stop-and-go operation into a continuous industrial assembly line.

How Multi-Chamber Furnaces Redefine Efficiency

The "magic" of a multi-chamber system lies in its logical separation of tasks. Instead of one chamber performing every step, specialized modules handle each phase of the heat treatment process, creating a far more efficient and robust system.

The Core Principle: Process Parallelization

A single-chamber furnace must complete a full thermal cycle for each load: pump down, heat up, hold, and then cool down. The entire furnace structure endures this cycle, creating significant downtime where no productive work is done.

Multi-chamber furnaces eliminate this wasted time. A load is heated in a dedicated hot chamber, then transferred to a separate cooling or quenching chamber, allowing the next load to immediately enter the hot zone.

Benefit 1: Dramatically Increased Throughput

This parallel processing is the key to higher productivity. By keeping the hot chamber constantly at temperature and ready for the next load, the "recovery time" between batches is virtually eliminated.

Pump-down times are also shortened because the hot chamber can remain under vacuum. This continuous flow significantly reduces the overall processing time per part and increases the total output of the furnace.

Benefit 2: Superior Energy Efficiency

In a single-chamber design, enormous amounts of energy are wasted reheating the furnace's insulation and structural components from a cooled state for every load.

A multi-chamber design keeps the hot zone consistently hot. Energy is primarily used to heat the product itself, not the entire furnace apparatus, leading to a much lower energy cost per pound of processed material.

Benefit 3: Enhanced Component Lifespan and Lower Maintenance

The constant expansion and contraction from thermal cycling is the primary cause of fatigue and failure in furnace components like heating elements, fixtures, and insulation.

By maintaining a stable temperature in the hot chamber, a multi-chamber furnace minimizes this stress. This results in a significantly longer lifespan for critical components and a marked reduction in maintenance costs and downtime.

Understanding the Trade-offs

While the advantages are compelling, a multi-chamber system is not the universal solution. Acknowledging the trade-offs is critical for making an informed decision.

Higher Initial Capital Investment

A multi-chamber furnace is a more complex piece of equipment. It involves multiple chambers, vacuum-tight transfer mechanisms, and sophisticated automation, resulting in a higher upfront cost compared to a single-chamber unit.

Increased Complexity and Footprint

The system's advanced nature means more moving parts and more complex control systems. It also requires a larger physical footprint on the factory floor to accommodate the multiple chambers and transfer lines.

Best Suited for High-Volume Production

The efficiency gains of a multi-chamber furnace are most pronounced in high-volume, standardized production runs. For a job shop that processes many different small, custom batches with varying process parameters, the setup time might negate some of the throughput advantages.

Making the Right Choice for Your Operation

The decision between a single-chamber and multi-chamber furnace hinges entirely on your specific operational goals and production volume.

- If your primary focus is maximum throughput for a consistent product: A multi-chamber furnace is the definitive choice for achieving continuous flow and the lowest possible cost per part.

- If your primary focus is long-term operational cost (OpEx) reduction: The significant energy savings and lower maintenance needs of a multi-chamber design will deliver a strong return on the initial investment over time.

- If your primary focus is process flexibility for varied, low-volume jobs: A simpler, less expensive single-chamber furnace may offer a more practical solution with a lower barrier to entry.

Ultimately, choosing the right furnace technology requires a clear understanding of your process needs and financial objectives.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Increased Throughput | Parallel processing eliminates downtime, enabling continuous workflow |

| Superior Energy Efficiency | Stable hot chamber reduces energy waste, lowering cost per part |

| Lower Maintenance Costs | Minimized thermal cycling extends component lifespan |

Ready to transform your lab's efficiency with advanced furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to discuss how our multi-chamber vacuum furnaces can boost your throughput and reduce costs!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How do multi zone tube furnaces improve laboratory efficiency? Boost Throughput with Parallel Processing

- How are multi zone tube furnaces used in ceramics, metallurgy and glass research? Unlock Precise Thermal Control for Advanced Materials

- What are the benefits of integrating multiple heating zones in a tube furnace? Unlock Precise Thermal Control

- What is the difference between a tubular furnace and a muffle furnace? Choose the Right High-Temp Solution

- How are multi zone tube furnaces applied in biomedical research? Unlock Advanced Biomaterial Engineering