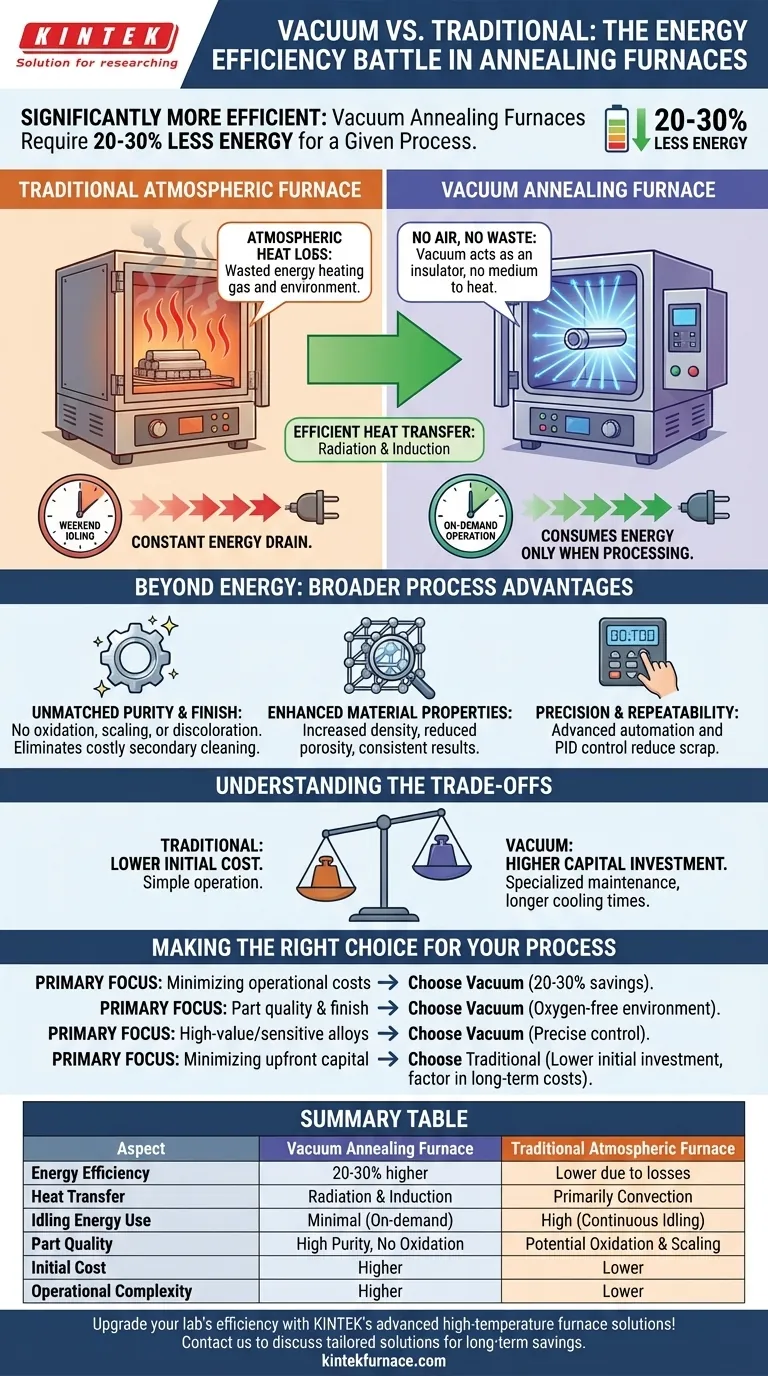

In a direct comparison, vacuum annealing furnaces are significantly more energy-efficient than their traditional atmospheric counterparts. They typically require 20-30% less energy for a given process, a saving that stems directly from their fundamental design and the physics of heating in a near-vacuum environment. This efficiency reduces operational costs and the overall environmental impact of the heat treatment process.

The energy efficiency of a vacuum furnace is not just a minor improvement; it is the result of a fundamentally different approach to heating. By removing the air, you eliminate the need to heat a massive, thermally inefficient atmosphere, allowing energy to be applied with greater precision and far less waste.

The Core Mechanisms of Vacuum Furnace Efficiency

To understand the energy savings, we must look at how each furnace type handles heat. The differences are stark and have significant consequences for energy consumption.

Eliminating Atmospheric Heat Loss

A traditional atmospheric furnace is essentially a hot box filled with air or a protective gas. A substantial amount of energy is wasted simply heating this gas, which then transfers that heat to the parts via convection.

A vacuum furnace, by contrast, removes nearly all of the air. With no atmosphere to heat, the energy is not wasted on an intermediary medium. The vacuum itself acts as an exceptional insulator, drastically reducing heat loss to the furnace walls and the surrounding environment.

Superior Heat Transfer Methods

In a vacuum, the primary method of heat transfer is radiation. At the high temperatures common in annealing, this is a highly efficient and direct way to heat the workload.

Furthermore, many modern vacuum furnaces use induction heating. This method uses electromagnetic fields to generate heat directly within the material itself. This is exceptionally efficient, as it bypasses external heating elements and the associated energy losses entirely.

On-Demand Operation vs. Continuous Idling

This is one of the most significant, yet often overlooked, sources of energy savings. Many traditional atmosphere furnaces must be kept at or near operating temperature continuously—even over weekends—to protect their refractory linings and avoid lengthy heat-up delays. This "weekend idling" represents a massive and constant energy drain.

Vacuum furnaces do not have this limitation. They can be heated up for a cycle and cooled down afterward, consuming significant energy only when they are actively processing parts.

Beyond Energy: The Broader Process Advantages

The benefits of a vacuum environment extend far beyond lower utility bills. The same characteristics that drive efficiency also produce a higher-quality product.

Unmatched Purity and Finish

By removing oxygen, vacuum furnaces completely prevent oxidation, scaling, and discoloration. Parts emerge from the furnace clean, bright, and with their original surface finish intact.

This often eliminates the need for costly and energy-intensive secondary operations like sandblasting, chemical pickling, or grinding, saving both time and resources.

Enhanced Material Properties

The clean, contaminant-free environment and precise temperature control of a vacuum furnace lead to superior metallurgical results. This includes increased material density, reduced porosity, and more consistent achievement of desired properties like hardness, strength, and ductility.

Precision and Repeatability

Advanced automation and PID (Proportional-Integral-Derivative) temperature control systems give vacuum furnaces exceptional precision. This ensures that every part in every batch receives the exact same thermal cycle, reducing scrap rates and eliminating the wasted energy associated with reprocessing failed batches.

Understanding the Trade-offs

While highly efficient, vacuum technology is not the default choice for every application. A balanced evaluation requires acknowledging its potential downsides.

Higher Initial Capital Investment

Vacuum furnaces are more complex systems, incorporating vacuum pumps, advanced controls, and specialized chamber construction. This typically results in a higher upfront purchase price compared to a simpler atmospheric furnace of similar size.

Cycle Time Considerations

While heating can be very rapid, cooling in a vacuum can be slow without assistance. For applications demanding fast cooling, furnaces must be equipped with a gas quenching system, which adds to the cost and complexity. This can impact overall throughput if not planned for.

Maintenance and Operational Complexity

The vacuum system—including pumps, seals, and instrumentation—requires specialized maintenance to ensure performance and reliability. Operators may also need more training to manage the process variables compared to a basic atmospheric furnace.

Making the Right Choice for Your Process

Your ideal solution depends on a clear understanding of your operational priorities, balancing initial cost against long-term performance and part quality.

- If your primary focus is minimizing operational costs: The 20-30% energy savings and complete elimination of idle energy consumption make vacuum furnaces a compelling long-term financial choice.

- If your primary focus is part quality and finish: The oxygen-free environment of a vacuum furnace is unparalleled, eliminating oxidation and often reducing the need for secondary cleaning operations.

- If your primary focus is processing high-value or sensitive alloys: The precise control and high-purity environment of vacuum technology are essential for achieving consistent, high-performance material properties.

- If your primary focus is minimizing upfront capital expenditure: A traditional atmospheric furnace may offer a lower initial investment, but you must carefully factor in the higher ongoing energy, labor, and potential post-processing costs.

Ultimately, choosing a vacuum furnace is an investment in process efficiency, superior part quality, and sustainable long-term operational savings.

Summary Table:

| Aspect | Vacuum Annealing Furnace | Traditional Atmospheric Furnace |

|---|---|---|

| Energy Efficiency | 20-30% higher | Lower due to atmospheric heating losses |

| Heat Transfer Method | Radiation and induction heating | Primarily convection |

| Idling Energy Use | Minimal (on-demand operation) | High (often continuous idling) |

| Part Quality | High purity, no oxidation | Potential oxidation and scaling |

| Initial Cost | Higher | Lower |

| Operational Complexity | Higher (requires specialized maintenance) | Lower |

Upgrade your lab's efficiency with KINTEK's advanced high-temperature furnace solutions! By leveraging our exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable vacuum annealing furnaces that cut energy use by 20-30%, reduce operational costs, and ensure superior part quality. Our product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by strong deep customization to meet your unique experimental needs. Don't let inefficiency hold you back—contact us today to discuss how our tailored solutions can transform your heat treatment processes and deliver long-term savings!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?