In short, a high-quality vacuum heat treatment furnace is defined by its ability to precisely control temperature and maintain an extremely pure, controlled environment. These core capabilities, enabled by sophisticated components, ensure the final product has superior mechanical properties, an impeccable surface finish, and predictable consistency from batch to batch.

The true mark of a superior furnace is not a single feature, but how its entire system—from vacuum pumps to control software—works in concert to deliver repeatable, high-integrity results while minimizing operational costs and product defects.

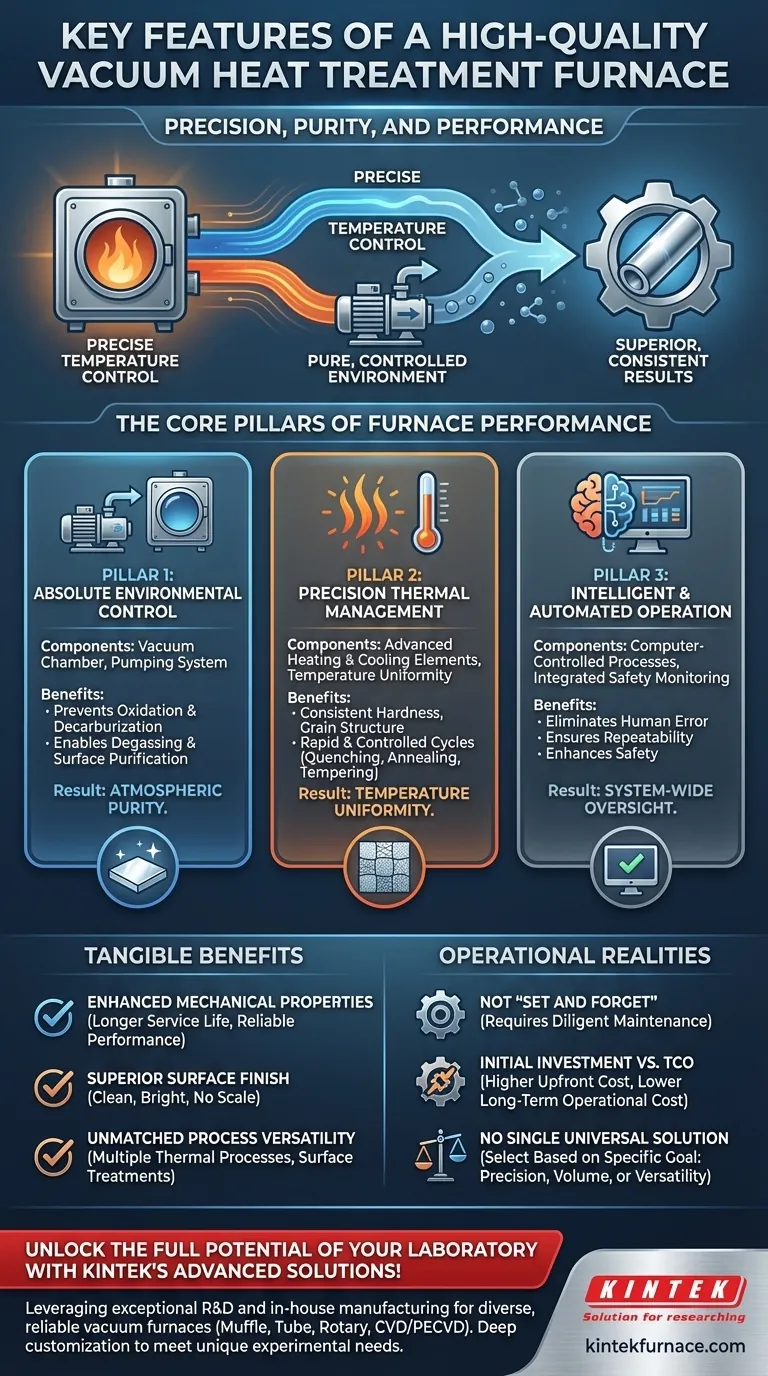

The Core Pillars of Furnace Performance

Understanding a vacuum furnace requires looking beyond a simple list of parts. Its quality is a function of how three core systems work together to manipulate a material's properties in a controlled environment.

Pillar 1: Absolute Environmental Control

The primary function of a vacuum furnace is to remove the atmosphere, which is the source of most heat-treating defects.

The Vacuum Chamber and Pumping System are the heart of this process. A high-quality system achieves a deep vacuum quickly, effectively eliminating oxygen and other reactive gases. This prevents oxidation and decarburization, which can compromise a part's surface and structural integrity.

Atmospheric Purity is a direct result. By removing air, the furnace also removes contaminants. This allows for processes like degassing and surface purification, where impurities are literally pulled out of the material itself, resulting in a cleaner, stronger final product.

Pillar 2: Precision Thermal Management

A furnace's ability to manage heat is what drives the metallurgical transformation. Inconsistency here leads directly to inconsistent results.

Temperature Uniformity is the most critical feature. A top-tier furnace ensures that all parts of the workpiece, regardless of their position in the chamber, experience the exact same temperature. This uniformity is essential for achieving consistent hardness, grain structure, and mechanical properties across the entire batch.

Advanced Heating and Cooling Elements enable rapid and controlled temperature changes. High thermal efficiency allows the furnace to heat up quickly, while integrated cooling systems (using gas or other media) allow for controlled quenching. This speed and control are vital for executing specific heat treat cycles like quenching, annealing, and tempering accurately.

Pillar 3: Intelligent and Automated Operation

Modern furnaces are not simple ovens; they are sophisticated, automated machines designed for repeatability and safety.

Computer-Controlled Processes are standard in high-quality equipment. A robust control system allows operators to program, execute, and monitor complex heat treatment cycles with high precision. This automation eliminates human error and ensures every batch is processed identically.

Integrated Safety and Monitoring provides system-wide oversight. These systems monitor vacuum levels, temperatures, and gas flows, ensuring safe operation and immediately alerting operators to any deviations from the desired process parameters.

The Tangible Benefits of a Superior System

These engineering features translate directly into measurable improvements in your products and your process.

Enhanced Mechanical Properties

By preventing surface reactions and ensuring uniform heat application, the furnace minimizes internal stresses and avoids issues like hydrogen embrittlement. This results in parts with a longer service life and more reliable performance under load.

Superior Surface Finish

The absence of oxygen means parts emerge from the furnace clean, bright, and free of scale. This "surface bright purification" often eliminates the need for costly and time-consuming secondary cleaning or finishing operations.

Unmatched Process Versatility

A single, high-quality vacuum furnace is capable of performing a wide array of thermal processes. This includes quenching, annealing, tempering, brazing, sintering, and even surface treatments like carburizing and nitriding, making it a highly versatile asset.

Understanding the Trade-offs and Operational Realities

While the benefits are clear, a high-quality vacuum furnace is a significant investment with specific operational requirements.

The Myth of "Set and Forget"

Even the most automated furnace requires diligent maintenance. Regular inspection and cleaning of the vacuum chamber, heating elements, and pumps are non-negotiable. Seals, sensors, and other components must be checked and replaced to ensure the system maintains its integrity and performance.

Initial Investment vs. Total Cost of Ownership

A superior furnace commands a higher initial price due to its precision components and advanced automation. However, this cost is often offset over time by a higher product pass rate, reduced scrap, lower energy consumption, and the elimination of secondary processing steps.

No Single Furnace is a Universal Solution

While highly versatile, a single furnace configuration may not be optimal for every conceivable process. Specialized applications, such as high-pressure gas quenching for specific alloys, may require purpose-built designs to achieve the best possible results.

Making the Right Choice for Your Goal

Selecting a furnace requires aligning its capabilities with your primary objective.

- If your primary focus is high-precision components (e.g., aerospace, medical): Prioritize exceptional temperature uniformity and high-vacuum integrity to guarantee consistent metallurgical properties and zero surface contamination.

- If your primary focus is high-volume production: Focus on rapid heating/cooling cycles, robust automation, and energy efficiency to maximize throughput and minimize the cost per part.

- If your primary focus is process versatility for R&D or a job shop: Ensure the furnace's control system and chamber design can accommodate a wide range of temperatures, pressures, and quench rates.

Ultimately, investing in a high-quality vacuum furnace is an investment in process control and final product quality.

Summary Table:

| Feature Category | Key Components | Benefits |

|---|---|---|

| Environmental Control | Vacuum chamber, pumping system | Prevents oxidation, decarburization; enables degassing and surface purification |

| Thermal Management | Heating elements, cooling systems | Ensures temperature uniformity, rapid heating/cooling for consistent hardness and grain structure |

| Operation & Automation | Computer controls, safety monitoring | Eliminates human error, ensures repeatability, and enhances safety |

Unlock the full potential of your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable vacuum heat treatment furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental needs, delivering superior mechanical properties, impeccable surface finishes, and unmatched process consistency. Contact us today to discuss how our tailored solutions can optimize your heat treatment processes and drive your success!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability