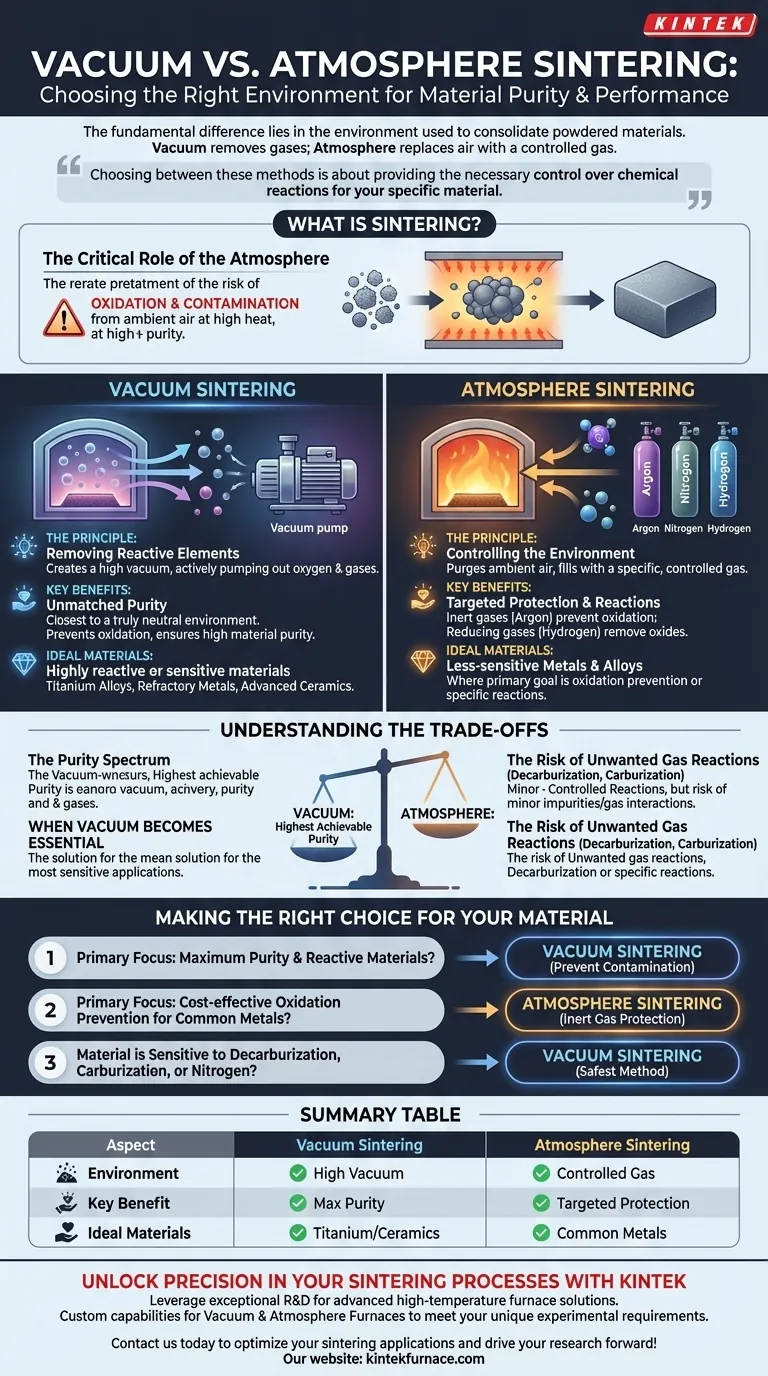

The fundamental difference between vacuum and atmosphere sintering lies in the environment used to consolidate powdered materials. Vacuum sintering functions by removing virtually all gases to create a highly pure, inert space. In contrast, atmosphere sintering works by replacing ambient air with a specific, controlled gas like argon or nitrogen to achieve a protective or reactive environment. This choice directly dictates the final purity and chemical integrity of the sintered part.

Choosing between these methods is not about which is inherently better, but which provides the necessary control over chemical reactions for your specific material. The decision hinges on balancing the need for absolute purity against process requirements and material compatibility.

What is Sintering? A Foundational Overview

The Goal: Fusing Powders into Solids

Sintering is a thermal process that uses heat to bond powder particles together, forming a solid, dense object without melting the material outright.

The Critical Role of the Atmosphere

The environment inside the furnace is critical. At elevated temperatures, materials become highly reactive, and contact with oxygen or other gases in the air can cause oxidation and contamination, severely degrading the final component's properties.

A Deep Dive into Vacuum Sintering

The Principle: Removing Reactive Elements

Vacuum sintering operates by creating a high vacuum inside the furnace, actively pumping out oxygen, nitrogen, and other potentially reactive gases.

Key Benefits: Unmatched Purity

By removing nearly all atmospheric particles, this method provides the closest possible state to a truly neutral environment. This prevents oxidation and ensures extremely high material purity, which is critical for high-performance applications.

Ideal Materials: When to Choose Vacuum

This process is essential for highly reactive or sensitive materials where even trace impurities are unacceptable. This includes titanium alloys, refractory metals, and many advanced ceramics.

A Deep Dive into Atmosphere Sintering

The Principle: Controlling the Environment

This method involves purging the furnace of ambient air and filling it with a specific, carefully controlled gas. The choice of gas is deliberate.

Key Benefits: Targeted Protection and Reactions

Common atmospheres include inert gases like argon to simply prevent oxidation. Alternatively, reducing gases like hydrogen can be used to actively remove surface oxides from the material during the process.

Ideal Materials: When to Choose Atmosphere

Atmosphere sintering is a practical and widely used method for less-sensitive metals and alloys where the primary goal is oxidation prevention. It is also used when a specific gas is required to facilitate a desired chemical reaction on the material's surface.

Understanding the Trade-offs

The Purity Spectrum

Vacuum sintering offers the highest achievable level of purity. While atmosphere sintering is effective for protection, the controlled gas itself can be a source of minor impurities compared to the near-total absence of gas in a vacuum.

The Risk of Unwanted Gas Reactions

Some materials are sensitive not just to oxygen, but to the protective gases themselves. A material prone to decarburization (loss of carbon) or carburization (gain of carbon) may react unfavorably even with the controlled atmosphere.

When Vacuum Becomes Essential

Vacuum is the superior choice when even so-called inert or reducing gases are unsuitable for the material. It provides a universal solution for preventing nearly all unwanted gas-material interactions, making it the safest option for the most sensitive applications.

Making the Right Choice for Your Material

Your material's chemical reactivity and the required final purity are the decisive factors in this choice. Use these guidelines to make a sound decision.

- If your primary focus is maximum purity and processing reactive materials: Vacuum sintering is the necessary choice to prevent any form of contamination or unwanted reaction.

- If your primary focus is cost-effective oxidation prevention for common metals: Atmosphere sintering with an inert gas like argon provides excellent and sufficient protection.

- If your material is sensitive to decarburization, carburization, or reacting with nitrogen: Vacuum sintering is the safest method to ensure the material's chemical composition remains unchanged.

By deliberately choosing your sintering environment, you gain precise control over the final integrity and performance of your component.

Summary Table:

| Aspect | Vacuum Sintering | Atmosphere Sintering |

|---|---|---|

| Environment | High vacuum, removes gases | Controlled gas (e.g., argon, hydrogen) |

| Key Benefit | Maximum purity, prevents oxidation | Targeted protection or reactions |

| Ideal Materials | Titanium alloys, refractory metals, sensitive ceramics | Common metals, alloys requiring specific gas reactions |

Unlock Precision in Your Sintering Processes with KINTEK

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you need vacuum sintering for ultimate purity or atmosphere sintering for cost-effective protection, we deliver tailored solutions that enhance material integrity and performance.

Contact us today via our contact form to discuss how our furnaces can optimize your sintering applications and drive your research forward!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- How is the sealing performance of an experimental box type atmosphere furnace enhanced? Boost Purity with Advanced Sealing Systems

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling