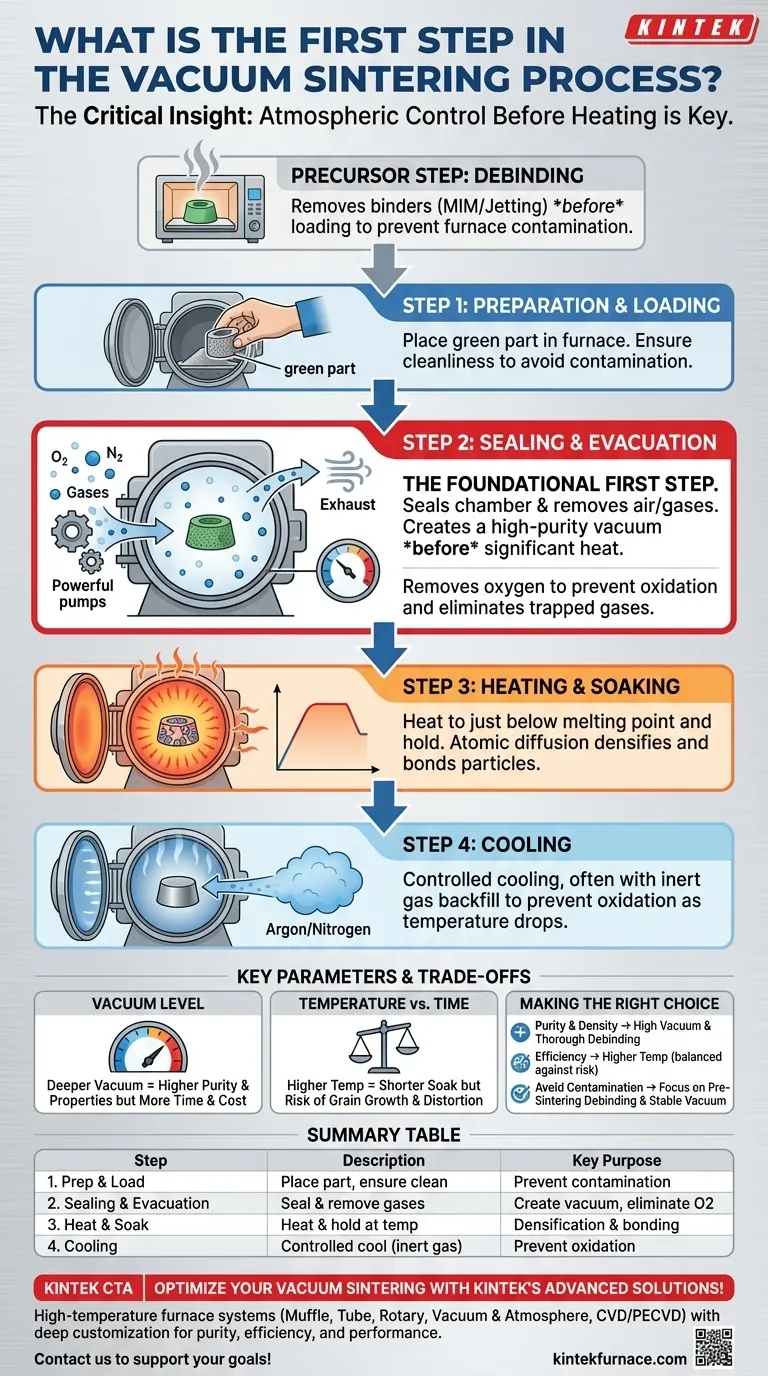

The first step in the vacuum sintering process is the physical preparation and loading of the material, or "green part," into the furnace. Immediately following this, the chamber is sealed, and the evacuation process begins to create a vacuum. This removal of atmosphere is the foundational step that defines the entire process, occurring before any significant heat is applied.

The critical insight is that vacuum sintering is fundamentally an atmospheric control process. Creating a high-purity vacuum environment before heating is not just the first step; it is the most crucial one for preventing oxidation and ensuring the metallurgical integrity of the final component.

Deconstructing the Vacuum Sintering Cycle

Vacuum sintering is a multi-stage thermal process that uses a vacuum to create high-performance, dense parts from powdered materials. Each step is precisely controlled to achieve the desired final properties.

Step 1: Preparation and Loading

The process begins with the "green part," a component formed from metal powder that is held together by pressure or a binder. This part is carefully placed inside the vacuum furnace. Cleanliness at this stage is paramount to prevent contamination.

Step 2: Sealing and Evacuation

Once loaded, the furnace chamber is sealed to be airtight. Powerful pumps then begin to remove the air and other gases from the chamber. This evacuation creates the vacuum environment essential for the process.

The primary purpose of the vacuum is to remove oxygen, which would otherwise react with the hot metal, causing oxidation and compromising the part's quality. It also helps remove any trapped gases within the powder compact.

Step 3: Heating and Soaking

With the vacuum established, the furnace begins to heat up in a controlled manner. The temperature is raised to just below the material's melting point.

The part is then held at this peak temperature for a specific duration, a phase known as "soaking" or "holding." During this time, the metal particles bond together on an atomic level, a process called diffusion, which reduces porosity and densifies the part.

Step 4: Cooling

After the soaking phase is complete, the furnace is cooled down in a controlled sequence. Sometimes, an inert gas like argon or nitrogen is backfilled into the chamber to help accelerate cooling and prevent oxidation as the part's temperature drops.

Understanding Key Parameters and Trade-offs

Simply following the steps is not enough; mastering the process requires understanding the interplay between its critical variables.

The Debinding Precursor

For parts made using processes like Metal Injection Molding (MIM) or binder jetting, a critical step called debinding must occur before the part is loaded into the sintering furnace. This separate process removes the binder materials that give the green part its initial shape.

Attempting to sinter a part without proper debinding would cause the binder to burn off inside the vacuum furnace, contaminating the chamber and compromising the final product. For this reason, some consider debinding the true "first step" of the overall manufacturing workflow.

The Critical Role of the Vacuum Level

The "depth" of the vacuum (how much air is removed) is a key parameter. A deeper vacuum provides a cleaner environment, leading to higher purity and better mechanical properties. However, achieving and maintaining a high vacuum requires more time and more expensive equipment.

Temperature vs. Time

Sintering temperature and soaking time are directly related. A higher temperature can sometimes reduce the required soaking time. However, excessive heat risks grain growth, which can make the material brittle, or even partial melting, which distorts the part's final shape. The goal is to find the optimal balance for the specific alloy being processed.

Making the Right Choice for Your Goal

The specific parameters of the vacuum sintering cycle should be tailored to the desired outcome for the final component.

- If your primary focus is maximum purity and density: You must prioritize a high vacuum level and ensure that a thorough debinding process is completed before sintering begins.

- If your primary focus is process efficiency: You may experiment with slightly higher sintering temperatures to reduce soak times, but this must be carefully balanced against the risk of grain growth or distortion.

- If your primary focus is avoiding part contamination: Your attention must be on the initial stages—thorough pre-sintering debinding and achieving a clean, stable vacuum before the heating cycle starts.

Understanding that each stage sets the foundation for the next is the key to mastering the vacuum sintering process.

Summary Table:

| Step | Description | Key Purpose |

|---|---|---|

| 1. Preparation and Loading | Place the green part into the furnace | Ensure cleanliness and prevent contamination |

| 2. Sealing and Evacuation | Seal the chamber and remove air/gases | Create a vacuum to eliminate oxygen and trapped gases |

| 3. Heating and Soaking | Heat to just below melting point and hold | Enable diffusion for densification and bonding |

| 4. Cooling | Controlled cooling, often with inert gas | Prevent oxidation and achieve final properties |

Optimize your vacuum sintering process with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, enhancing purity, efficiency, and performance. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- Why is a high-vacuum environment necessary in copper slag impoverishment? Maximize Your Matte Separation Efficiency

- What processing conditions does a vacuum furnace provide for TiCp/Fe microspheres? Sintering at 900 °C

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance