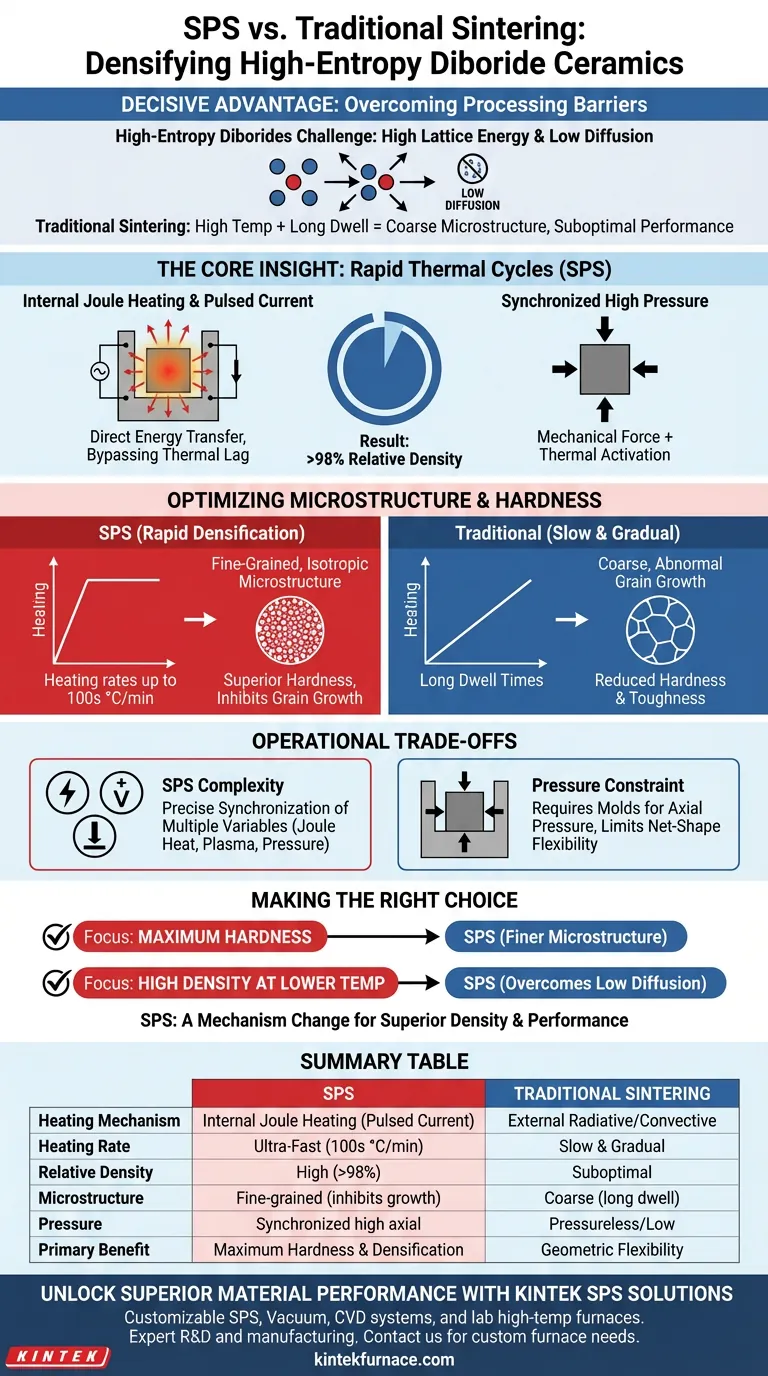

Spark Plasma Sintering (SPS) systems provide a decisive advantage by overcoming the inherent processing barriers of high-entropy diboride ceramics through a combination of pulsed electric currents and synchronized high pressure. Unlike traditional sintering furnaces that rely on external heating, SPS facilitates internal Joule heating, allowing you to achieve relative densities exceeding 98% at lower temperatures while preserving superior hardness.

The Core Insight High-entropy diborides possess high lattice energy and low diffusion rates, making them notoriously difficult to densify without degrading their microstructure. SPS technology solves this by bypassing the need for prolonged high-temperature exposure, utilizing rapid thermal cycles to densify the material before grain coarsening can compromise its physical properties.

Overcoming the Diffusion Barrier

The Challenge of High Lattice Energy

High-entropy diborides are characterized by high lattice energy and inherently low atomic diffusion rates.

In traditional sintering scenarios, overcoming these barriers requires extremely high temperatures and long dwell times to drive densification. This often leads to coarse microstructures and suboptimal mechanical performance.

The Mechanism of Internal Heating

SPS systems address this by passing pulsed electric currents directly through the powder and the mold.

This generates internal heat (Joule heating) coupled with a plasma activation effect. This direct energy transfer significantly accelerates atomic diffusion, bypassing the thermal lag associated with traditional resistance or tube furnaces.

The Role of Synchronized Pressure

In addition to thermal energy, SPS utilizes a synchronized high-pressure environment.

This mechanical force works in tandem with the thermal activation to physically compact the material. This dual-action approach allows the ceramic to reach near-theoretical density levels (exceeding 98%) that would be difficult to achieve with pressureless sintering methods.

Optimizing Microstructure and Hardness

Achieving Rapid Densification

The most distinct operational advantage of SPS is the speed of the process.

SPS systems are capable of extremely high heating rates—up to several hundred degrees per minute. This allows the five carbide/diboride components to form a solid-solution single-phase structure in a very short period.

Inhibiting Grain Growth

Prolonged exposure to high heat causes grains to grow abnormally, which reduces the hardness and fracture toughness of the final ceramic.

Because SPS drastically shortens the holding time and lowers the required sintering temperature, it effectively inhibits grain growth. The result is a fine-grained, isotropic microstructure that exhibits superior hardness compared to materials processed in traditional hot pressing furnaces.

Understanding the Operational Trade-offs

Complexity of Parameter Control

While traditional furnaces often rely on simple temperature-over-time profiles, SPS requires the precise synchronization of multiple variables.

Operators must manage pulsed current, voltage, and mechanical pressure simultaneously. The process relies on the successful generation of Joule heat and plasma activation, meaning the electrical conductivity of the mold and sample setup becomes a critical process variable that is not present in standard radiative heating.

The Constraint of Pressure Application

SPS is inherently a pressure-assisted process.

Unlike pressureless sintering, which allows for complex net-shape manufacturing in batch quantities, SPS requires the sample to be contained within a mold capable of transmitting axial pressure. This physical constraint is the necessary trade-off for achieving high density at lower thermal loads.

Making the Right Choice for Your Project

The decision to switch from traditional sintering to SPS depends on your specific performance requirements for the diboride ceramic.

- If your primary focus is Maximum Hardness: SPS is the superior choice, as its rapid thermal cycle prevents grain coarsening, resulting in a finer microstructure and harder material.

- If your primary focus is High Density at Lower Temperatures: SPS is essential, as it overcomes the low diffusion rates of high-entropy materials to achieve >98% density where traditional furnaces fail.

Ultimately, SPS is not just a faster furnace; it is a mechanism change that trades geometric flexibility for superior material density and mechanical performance.

Summary Table:

| Feature | Spark Plasma Sintering (SPS) | Traditional Sintering Furnaces |

|---|---|---|

| Heating Mechanism | Internal Joule Heating (Pulsed Current) | External Radiative/Convective Heating |

| Heating Rate | Ultra-Fast (up to 100s of °C/min) | Slow and Gradual |

| Relative Density | High (>98% near-theoretical) | Suboptimal due to low diffusion |

| Microstructure | Fine-grained (inhibits grain growth) | Coarse (due to long dwell times) |

| Pressure | Synchronized high axial pressure | Often pressureless or low pressure |

| Primary Benefit | Maximum hardness and densification | Geometric flexibility for complex shapes |

Unlock Superior Material Performance with KINTEK SPS Solutions

Are you struggling to densify high-entropy ceramics without compromising microstructure? Backed by expert R&D and manufacturing, KINTEK offers cutting-edge Spark Plasma Sintering (SPS), Vacuum, CVD systems, and other lab high-temp furnaces, all fully customizable to meet your unique material science challenges.

Our advanced SPS technology ensures you achieve maximum hardness and near-theoretical density for your most demanding projects. Contact us today to discuss your custom furnace needs and see how our expertise in high-temperature engineering can accelerate your research and production.

Visual Guide

References

- Yajun Lv, Weizhun Jin. Preparation and Properties of Porous Concrete Based on Geopolymer of Red Mud and Yellow River Sediment. DOI: 10.3390/ma17040923

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- How does a horizontal vacuum furnace handle different part sizes? Optimize Loading for Uniform Heating

- Why is a high-vacuum environment necessary for gold electrode deposition? Key to Solar Cell Efficiency

- What are the types of vacuum furnaces based on heating form? Internal vs. External Heating Explained

- What role does a laboratory drying oven or vacuum oven play in graphene oxide nanofluid prep? Ensure Pure Formulations

- Why is a vacuum drying oven utilized for the annealing treatment of ion-conductive polymer films? Enhance Film Stability

- What key experimental environments do vacuum resistance furnaces provide for Ti–50Zr alloys? Ensure Material Purity

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- How are vacuum annealing furnaces used in solar cell manufacturing? Boost Efficiency with Precision Heat Treatment