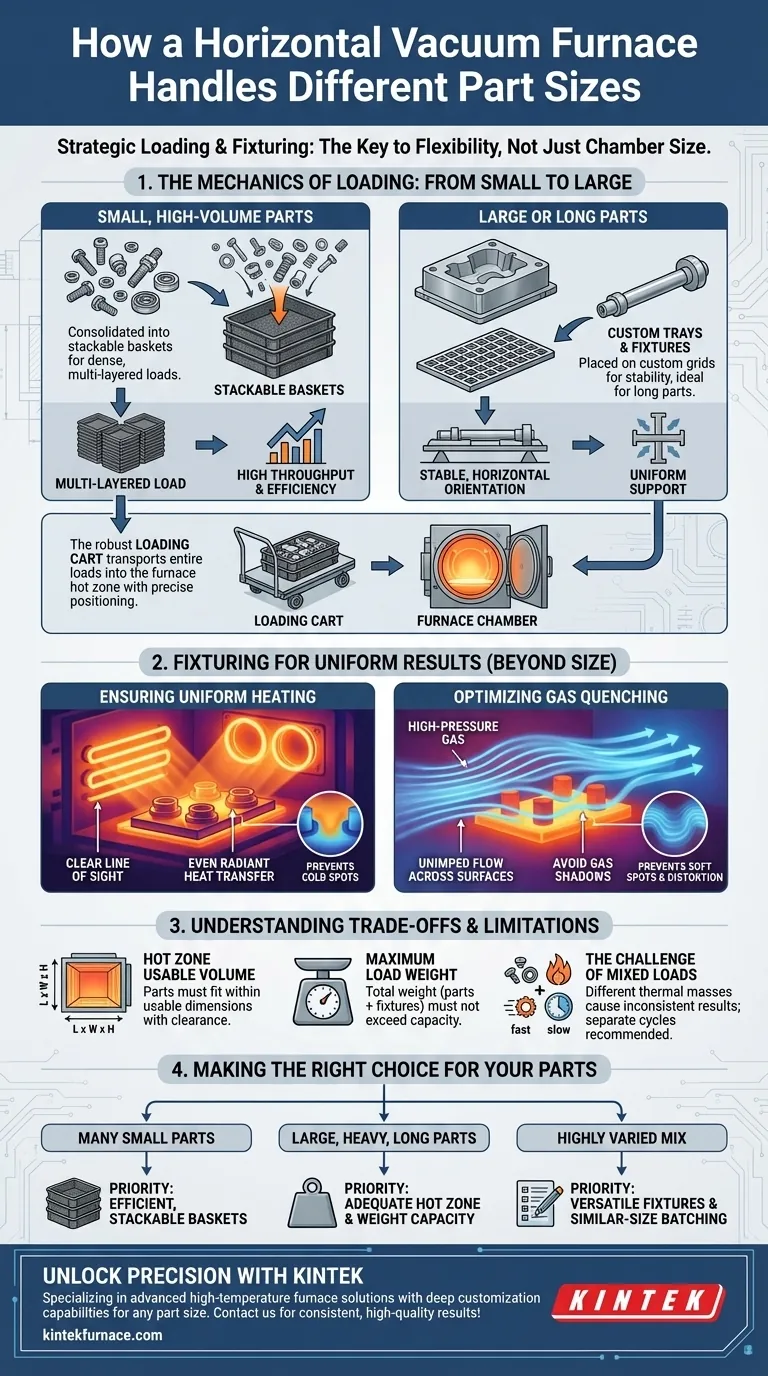

At its core, a horizontal vacuum furnace accommodates different part sizes through strategic loading and fixture design. This is not an automatic process but a methodical one. Small components are typically consolidated into stackable baskets, while larger parts are placed on custom trays or fixtures, all of which are then moved into the furnace chamber using a specialized loading cart.

The furnace's flexibility comes not from the chamber itself, but from the adaptable loading systems and internal fixtures used. The goal is to arrange parts within the hot zone to ensure uniform heating and quenching, regardless of their individual size or shape.

The Mechanics of Loading: From Small to Large

A furnace's ability to handle various part sizes depends entirely on the systems used to contain and transport those parts into the hot zone.

Handling Small, High-Volume Parts

For small pieces like fasteners, bearings, or medical implants, efficiency is key. These parts are loaded into stackable baskets, often made of graphite or molybdenum alloys.

Multiple baskets can be stacked on a single base, creating a dense, multi-layered load. This approach maximizes the number of parts per cycle, increasing throughput significantly.

Accommodating Large or Long Parts

Large, singular components like die-casting molds, aerospace structures, or long shafts are handled differently. They are typically placed on custom-designed grids, trays, or specialized fixtures.

The horizontal orientation of the furnace is particularly advantageous for long, slender parts that can be laid flat, ensuring stability and uniform support during the thermal cycle.

The Role of the Loading Cart

The loading cart is the critical link between the staging area and the furnace. It is a robust, wheeled platform designed to carry the immense weight of a full load, whether it's a stack of baskets or a single, massive fixture.

This cart aligns perfectly with the furnace opening, allowing an operator to smoothly and safely push the entire load into the hot zone, ensuring precise and repeatable positioning for every cycle.

Beyond Size: Fixturing for Uniform Results

Simply fitting parts into the furnace is not enough. The way they are arranged—the fixturing—is critical for achieving the desired metallurgical properties.

Ensuring Uniform Heating

Proper fixturing ensures that a clear line of sight exists between the heating elements and the part surfaces. It also prevents parts from touching, which would create cold spots.

The goal is to allow for even radiant heat transfer and, in convection-assisted furnaces, uniform gas flow around every component in the load.

Optimizing Gas Quenching

During the cooling phase, high-pressure gas must flow unimpeded across all critical surfaces of a part. Dense packing or poor fixture design can create "gas shadows."

These shadows block the quench gas, leading to slow or non-uniform cooling. The result can be soft spots, inconsistent hardness, and increased distortion, compromising the integrity of the final product.

Understanding the Trade-offs and Limitations

While versatile, horizontal vacuum furnaces are not without constraints that you must factor into your operational planning.

Hot Zone Usable Volume

The most fundamental limitation is the usable dimensions of the hot zone (length, width, and height). Any part, including its fixture, must physically fit within this space with adequate clearance from the heating elements and chamber walls.

Maximum Load Weight

Every furnace has a maximum weight capacity. This limit includes the weight of the parts themselves plus the substantial weight of the graphite or metallic baskets and fixtures holding them. Overloading can damage the hearth support structure and the loading mechanism.

The Challenge of Mixed Loads

Processing very large, massive parts alongside very small, light parts in the same cycle is technically challenging. Their different thermal masses cause them to heat and cool at vastly different rates.

This discrepancy can make it difficult to achieve the correct metallurgical properties for both part types simultaneously, often forcing operators to run separate, optimized cycles for each.

Making the Right Choice for Your Parts

To leverage the furnace's flexibility, match your loading strategy to your production needs.

- If your primary focus is many small, uniform parts: Prioritize a system with efficient, stackable baskets to maximize batch density and throughput.

- If your primary focus is large, heavy, or long parts: Ensure the furnace's usable hot zone and weight capacity can accommodate your largest components and their required fixtures.

- If your primary focus is a highly varied mix of sizes: Develop a versatile set of fixtures and batch parts of similar size and mass together to ensure consistent quality across runs.

By mastering these loading principles, you transform the furnace from a simple chamber into a highly flexible and precise manufacturing tool.

Summary Table:

| Part Size | Loading Method | Key Benefits |

|---|---|---|

| Small, High-Volume | Stackable baskets | Maximizes throughput, efficient batch processing |

| Large or Long | Custom trays/fixtures | Ensures stability, uniform support |

| Mixed Sizes | Separate optimized cycles | Maintains consistent quality and properties |

Unlock Precision for Your Laboratory with KINTEK

Struggling to achieve uniform heat treatment for parts of varying sizes? KINTEK specializes in advanced high-temperature furnace solutions tailored to your needs. Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, whether you're handling small components or large, complex parts.

Contact us today to discuss how our furnaces can enhance your lab's efficiency and deliver consistent, high-quality results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today