A precise, slow cooling rate is essential during the heat treatment of Nb3Sn cavities to prevent the material from trapping ambient magnetic flux. By maintaining a strictly controlled rate, such as 0.1 K/min, you ensure the cavity reaches its optimal quality factor and that performance data reflects the actual coating quality rather than procedural errors.

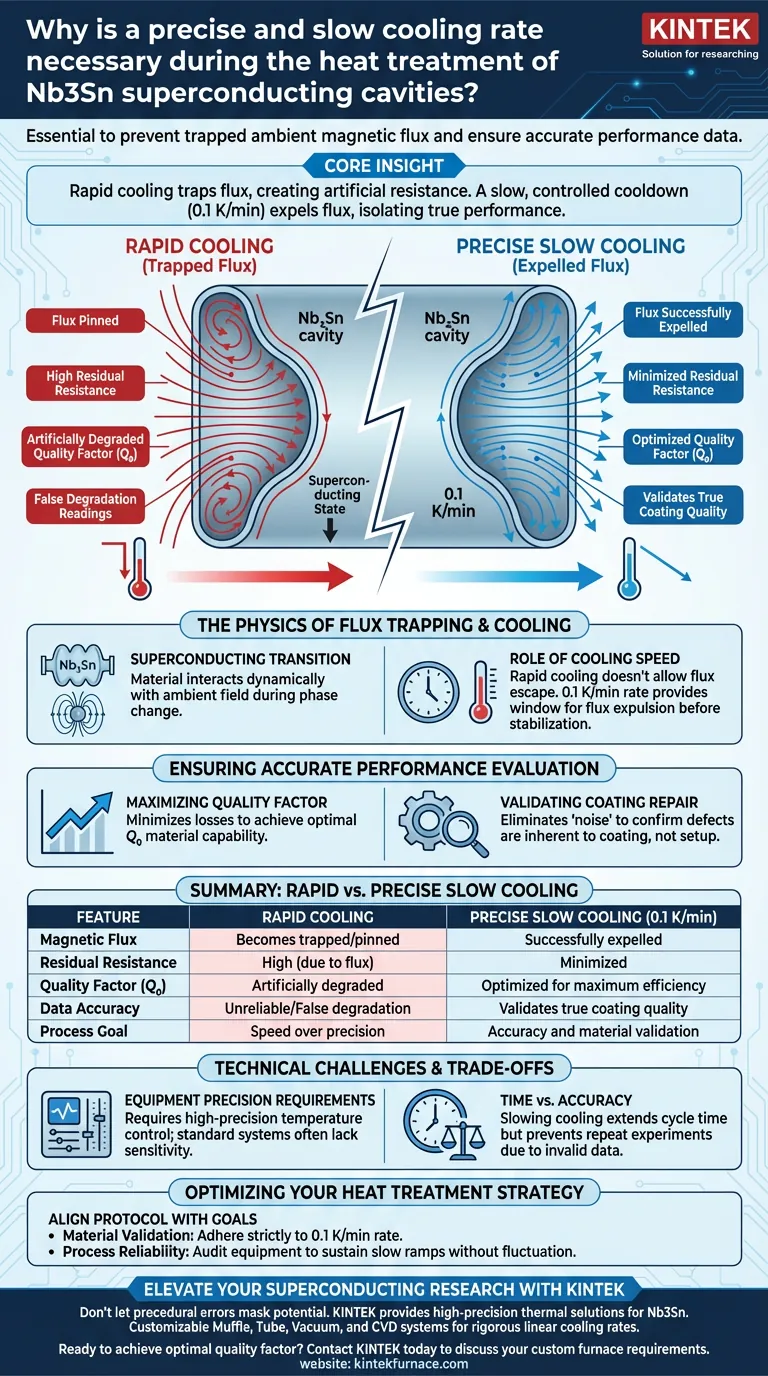

Core Insight: Rapid cooling traps magnetic flux within the superconductor, creating artificial resistance. A slow, controlled cooldown effectively expels this flux, isolating the coating's true performance characteristics and eliminating false degradation readings.

The Physics of Flux Trapping

Navigating the Superconducting Transition

When a niobium-tin (Nb3Sn) cavity cools below its critical temperature, it transitions into a superconducting state.

During this specific phase change, the material interacts dynamically with the ambient magnetic field surrounding it.

The Role of Cooling Speed

If the temperature drops too rapidly, the ambient magnetic flux does not have time to escape the material.

Instead, the flux becomes "pinned" or trapped inside the superconductor.

A precise, slow rate of 0.1 K/min provides the necessary time window for the material to expel this flux before the superconducting state fully stabilizes.

Ensuring Accurate Performance Evaluation

Maximizing the Quality Factor

Trapped magnetic flux is detrimental because it introduces residual resistance.

This resistance lowers the cavity's quality factor ($Q_0$), making the component appear less efficient than it actually is.

By using high-precision equipment to enforce slow cooling, you minimize these losses and achieve the optimal $Q_0$ the material is capable of supporting.

Validating the Coating Repair

The primary goal of testing is often to evaluate the success of a coating repair process.

Improper cooling introduces "noise" into this evaluation, causing false performance degradation.

Slow cooling acts as a control variable, ensuring that any measured defects are inherent to the coating itself, not artifacts of the experimental setup.

Technical Challenges and Trade-offs

Equipment Precision Requirements

Achieving a consistent 0.1 K/min rate is technically demanding.

It requires high-precision temperature control equipment capable of making micro-adjustments to maintain a linear and slow decline.

Standard cooling systems may lack the sensitivity required to prevent accidental rapid drops in temperature.

Time vs. Accuracy

The most immediate trade-off is the duration of the process.

Slowing the cooling rate significantly extends the cycle time for each heat treatment run.

However, this investment in time is necessary to prevent invalid data that would require the entire experiment to be repeated.

Optimizing Your Heat Treatment Strategy

To ensure valid results during Nb3Sn cavity testing, align your cooling protocol with your specific evaluation goals:

- If your primary focus is Material Validation: Adhere strictly to the 0.1 K/min rate to eliminate trapped flux as a variable in your quality factor measurements.

- If your primary focus is Process Reliability: Audit your temperature control equipment to ensure it can sustain slow ramps without fluctuation, preventing false degradation signals.

Precision in the cooling phase is the only way to reveal the true performance capability of your superconducting cavities.

Summary Table:

| Feature | Rapid Cooling | Precise Slow Cooling (0.1 K/min) |

|---|---|---|

| Magnetic Flux | Becomes trapped/pinned | Successfully expelled from material |

| Residual Resistance | High (due to flux trapping) | Minimized |

| Quality Factor ($Q_0$) | Artificially degraded | Optimized for maximum efficiency |

| Data Accuracy | Unreliable/False degradation | Validates true coating quality |

| Process Goal | Speed over precision | Accuracy and material validation |

Elevate Your Superconducting Research with KINTEK

Don't let procedural errors mask your material's potential. KINTEK provides the high-precision thermal solutions necessary for sensitive Nb3Sn heat treatments. Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Vacuum, and CVD systems designed to maintain the rigorous linear cooling rates required by advanced lab applications.

Ready to achieve the optimal quality factor for your high-temp lab needs? Contact KINTEK today to discuss your custom furnace requirements.

Visual Guide

References

- Eric Viklund, Grigory Eremeev. Healing gradient degradation in Nb3Sn SRF cavities using a recoating method. DOI: 10.1063/5.0218739

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the advantages of a mesh belt brazing furnace vs vacuum? Optimize High-Volume Stainless Steel Production

- How does vacuum or protective atmosphere melting improve the quality of aerospace materials? Achieve Superior Purity and Performance

- Why is a high-performance vacuum system critical for Gallium Sulfide crystal sealing? Ensure 10^-6 Torr Purity

- Why is a vacuum heating and cooling stage necessary for SWCNT research? Unlock Precision in Thermal Conductivity

- Why are graphite fixtures and holders important in vacuum furnaces? Unlock Precision & Durability

- What is the function of a Vacuum Arc Furnace in the synthesis of MNiSn alloys? Ensure High Purity & Precise Doping

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- What is sintering in a vacuum atmosphere? Achieve Maximum Purity for High-Performance Parts