A vacuum heating and cooling stage is critical for studying Single-Walled Carbon Nanotubes (SWCNTs) because it creates the only environment where intrinsic thermal properties can be measured accurately. This equipment eliminates external variables—specifically air currents—and provides the precise thermal control necessary to observe how heat moves through the material at the atomic level.

By removing convective heat transfer and stabilizing substrate temperatures, this setup ensures that any measured thermal activity is the result of phonon interactions within the material, rather than environmental noise.

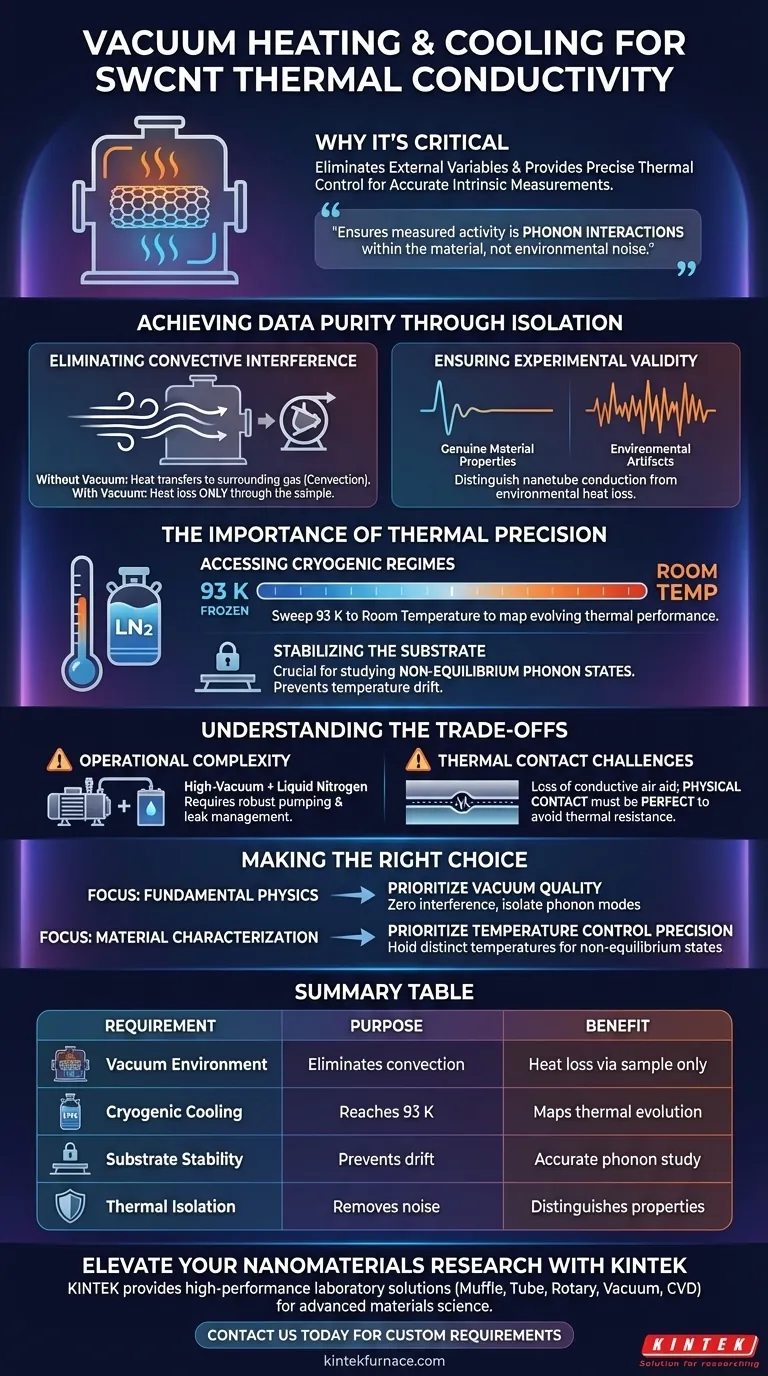

Achieving Data Purity through Isolation

To understand the thermal conductivity of SWCNTs, you must first eliminate the mechanisms that obscure the data.

Eliminating Convective Interference

The primary enemy of accurate thermal measurement at this scale is convection.

If air is present, heat will transfer from the sample to the surrounding gas. A vacuum environment removes these air molecules, ensuring that heat loss occurs only through the sample itself.

Ensuring Experimental Validity

Without a vacuum, it is impossible to distinguish between the heat conducted by the nanotube and the heat lost to the environment.

The vacuum stage guarantees that the thermal diffusion phenomena you observe are genuine material properties, not artifacts of the test environment.

The Importance of Thermal Precision

Studying SWCNTs requires rigorous control over the temperature of the substrate supporting the sample.

Accessing Cryogenic Regimes

Thermal conductivity changes drastically with temperature.

By combining the stage with a liquid nitrogen cooling system, researchers can sweep a temperature range from 93 K to room temperature. This wide range is essential for mapping how thermal performance evolves from cryogenic conditions to ambient warmth.

Stabilizing the Substrate

The heating and cooling stage does not just reach a target temperature; it effectively "locks" it in.

Precisely maintaining the substrate temperature is required to study non-equilibrium phonon states. If the base temperature drifts, the data regarding these delicate vibrational states becomes unreliable.

Understanding the Trade-offs

While necessary for high-fidelity data, using a vacuum heating and cooling stage introduces specific complexities to the experiment.

Operational Complexity

Integrating a liquid nitrogen system with high-vacuum equipment increases the difficulty of the experimental setup.

Maintaining a stable vacuum while cycling temperatures between 93 K and room temperature requires robust pumping systems and careful leak management to prevent condensation or pressure spikes.

Thermal Contact Challenges

In a vacuum, you lose the conductive aid of air molecules between the sample and the sensor.

This means the physical contact between the SWCNT and the measurement stage must be perfect. Poor contact in a vacuum results in significant thermal contact resistance, which can skew conductivity calculations.

Making the Right Choice for Your Goal

When configuring your apparatus for SWCNT research, consider your specific analytical objectives.

- If your primary focus is fundamental physics: Prioritize the vacuum quality to ensure zero convective interference, allowing for the isolation of pure phonon transport modes.

- If your primary focus is material characterization: Prioritize the precision of the temperature control, ensuring you can hold specific distinct temperatures (e.g., exactly 93 K) to capture non-equilibrium states accurately.

The ultimate value of this setup lies in its ability to strip away the noise of the physical world, leaving only the intrinsic behavior of the nanotube behind.

Summary Table:

| Requirement | Purpose in SWCNT Research | Benefit to Data Quality |

|---|---|---|

| Vacuum Environment | Eliminates convective heat transfer | Ensures heat loss occurs only through the sample itself |

| Cryogenic Cooling | Reaches temperatures as low as 93 K | Maps thermal performance evolution from cryogenic to ambient |

| Substrate Stability | Prevents base temperature drift | Allows accurate study of delicate non-equilibrium phonon states |

| Thermal Isolation | Removes environmental interference | Distinguishes genuine material properties from experimental noise |

Elevate Your Nanomaterials Research with KINTEK

Precise thermal characterization of SWCNTs requires an environment free from interference. KINTEK provides high-performance laboratory solutions designed to meet the rigorous demands of advanced materials science. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are fully customizable to your unique experimental needs.

Whether you are exploring fundamental physics or industrial applications, our equipment ensures the thermal stability and vacuum integrity your research deserves. Contact us today to discuss your custom furnace requirements and see how our expertise can bring unparalleled purity to your data.

Visual Guide

References

- Ibrahim Al Keyyam, Xinwei Wang. Direct Observation of Suppressed Optical–Acoustic Phonon Energy Coupling in Supported SWCNT at Cryogenic Temperatures. DOI: 10.1002/advs.202509005

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is the purpose of using industrial vacuum furnaces for 3003mod aluminum? Optimize H14 Temper & Material Stress

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- What precautions should be taken when handling samples in a vacuum furnace? Ensure Safety and Precision in Your Lab

- How do high-temperature vacuum furnaces influence the Fluorine (F) content on Niobium surfaces? Master Surface Purity

- What are the main types of vacuum furnaces? Choose the Right Type for Your Heat Treatment Needs

- Why must coated electrode sheets be dried for extended periods in a vacuum oven? Ensure Battery Purity and Performance

- What are the advantages of using a vacuum drying oven for BiOCl precursors? Ensure Purity and Sintering Efficiency

- What is the typical heating process for steel castings in an annealing furnace? Achieve Optimal Microstructure and Stress Relief