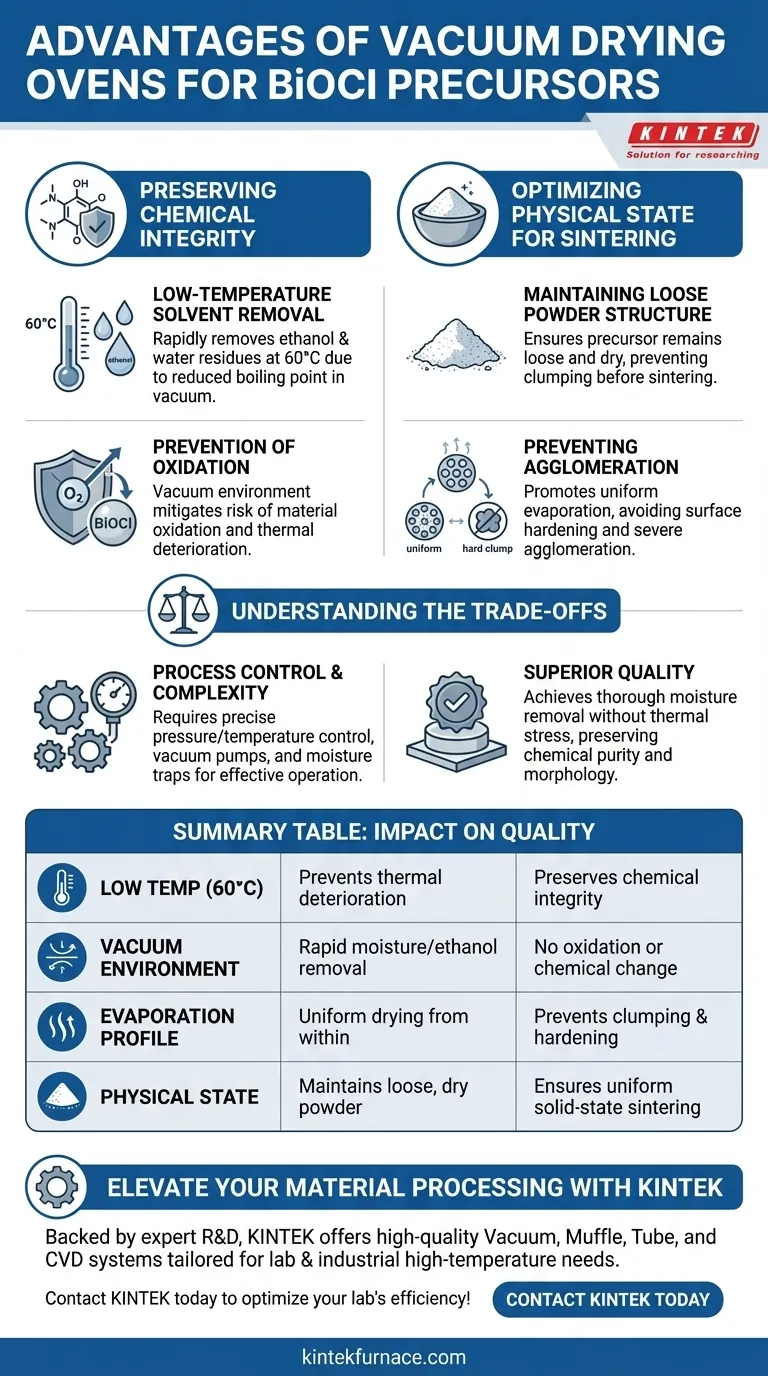

The primary advantage of using a vacuum drying oven for BiOCl precursors is the ability to rapidly remove moisture and ethanol residues at a controlled low temperature, typically 60°C. This process mitigates the risk of material oxidation or chemical deterioration while ensuring the precursor remains in a loose, dry physical state essential for successful solid-state sintering.

By lowering the boiling point of solvents, vacuum drying achieves thorough moisture removal without the thermal stress that compromises heat-sensitive materials. For BiOCl, this preserves both chemical purity and the physical morphology required for high-quality subsequent processing.

Preserving Chemical Integrity

Low-Temperature Solvent Removal

The synthesis of BiOCl precursors often involves washing with solvents like ethanol and water.

A vacuum environment significantly reduces the boiling point of these solvents. This allows them to evaporate rapidly at 60°C, a temperature far lower than what is required in a standard atmospheric oven.

Prevention of Oxidation

High temperatures are a catalyst for unwanted chemical reactions.

By drying at a lower temperature, the vacuum oven prevents material oxidation and thermal deterioration. This ensures the chemical composition of the BiOCl intermediate remains stable and pure.

Optimizing Physical State for Sintering

Maintaining a Loose Powder Structure

The physical state of the precursor is just as critical as its chemical makeup.

Vacuum drying ensures the BiOCl precursor remains in a loose and dry state. This is vital because the material must not clump together before it enters the next stage of production.

Preventing Agglomeration and Surface Hardening

Standard drying methods can cause "surface hardening," where the outer layer dries first and traps moisture inside, leading to hard clumps.

Vacuum drying promotes uniform evaporation from within the material pores. This prevents severe agglomeration, ensuring the powder remains free-flowing and ready for uniform solid-state sintering.

Understanding the Trade-offs

Process Control vs. Speed

While vacuum drying offers superior quality, it requires precise control over pressure and temperature variables.

Unlike simple air drying, operators must ensure the vacuum seal is intact and the pump is functioning correctly to maintain the low-pressure environment required for low-temperature evaporation.

Equipment Complexity

Vacuum drying ovens are more complex than standard convection ovens.

They require peripheral equipment, such as vacuum pumps and moisture traps, to handle the extracted solvents (ethanol/water). This adds a layer of operational complexity regarding maintenance and setup compared to atmospheric drying.

Making the Right Choice for Your Goal

To maximize the quality of your BiOCl precursors, align your drying strategy with your specific processing needs:

- If your primary focus is Chemical Purity: Utilize the vacuum oven at 60°C to eliminate oxidation risks and prevent thermal degradation of the active material.

- If your primary focus is Sintering Efficiency: Prioritize vacuum drying to prevent agglomeration, ensuring a loose powder that sinters uniformly.

Vacuum drying is not just a drying step; it is a critical preservation technique that defines the quality of your final BiOCl product.

Summary Table:

| Feature | Advantage for BiOCl | Impact on Quality |

|---|---|---|

| Low Temp (60°C) | Prevents thermal deterioration | Preserves chemical integrity |

| Vacuum Environment | Rapid moisture/ethanol removal | No oxidation or chemical change |

| Evaporation Profile | Uniform drying from within | Prevents clumping & hardening |

| Physical State | Maintains loose, dry powder | Ensures uniform solid-state sintering |

Elevate Your Material Processing with KINTEK

Precise drying is the foundation of high-performance BiOCl precursors. Backed by expert R&D and manufacturing, KINTEK offers high-quality Vacuum, Muffle, Tube, and CVD systems tailored for lab and industrial high-temperature needs. Whether you require standard vacuum drying ovens or fully customizable furnaces for unique sintering processes, our team ensures your materials maintain perfect chemical purity and morphology.

Ready to optimize your lab's efficiency? Contact KINTEK today to find the perfect drying solution for your specific application!

Visual Guide

References

- Yu‐Yun Lin, Chiing‐Chang Chen. Visible-Light-Driven Photocatalysis of Carbon Dioxide and Organic Pollutants by CaBiO2Cl/g-C3N4. DOI: 10.3390/molecules30183760

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does vacuum carburizing improve operational efficiency? Boost Speed, Quality, and Cost Savings

- Why is a precision vacuum drying oven required for processing electrode sheets in LMFP slurry coating? Essential Drying

- What are the advantages of using a vacuum drying oven for ceramic powders? Preserve Purity and Sinterability

- What is the maximum temperature a vacuum furnace can reach? Up to 2600°C for Advanced Materials Processing

- How do continuous vacuum furnaces improve energy efficiency in metal heat treatment? Achieve Superior Heat Treatment Efficiency

- What safety features are included in the vacuum furnace system? Essential Protection for Your Lab and Materials

- What types of metals and alloys are suitable for vacuum heat treatment furnaces? Essential Guide for High-Performance Materials

- What role do vacuum systems play in chemical processes? Master Precision Control for Gas-Sensitive Reactions