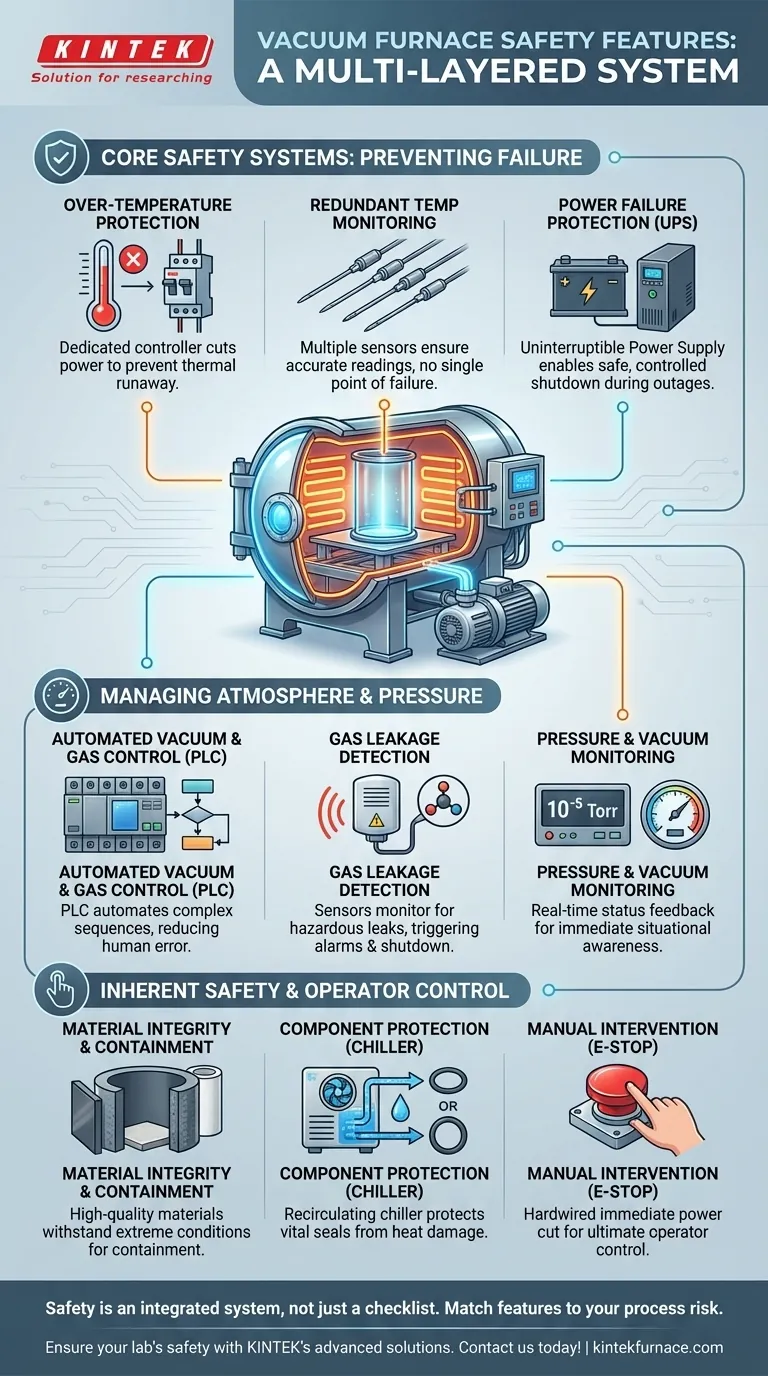

At its core, a modern vacuum furnace integrates a suite of safety features designed to protect the operator, the equipment, and the materials being processed. These systems include active controls like over-temperature protection that automatically cuts power, manual overrides such as an emergency stop button, and monitoring systems for vacuum levels and gas leakage. The furnace's physical construction, using high-integrity materials and component-level protections like cooling chillers, provides a passive layer of safety.

A vacuum furnace's safety is not derived from a single feature, but from a multi-layered system. This system combines automated controls to prevent predictable failures, robust materials to withstand extreme conditions, and manual overrides to give operators ultimate control in unforeseen circumstances.

Core Safety Systems: Preventing Catastrophic Failure

The highest priority in furnace safety is preventing events that could lead to equipment destruction or hazardous situations. This is achieved through several primary failsafe mechanisms.

Over-Temperature Protection

This is the most critical active safety feature. A dedicated controller, separate from the main process controller, monitors the furnace temperature. If it exceeds a preset safety limit, this system will automatically cut power to the heating elements, preventing a thermal runaway event.

Redundant Temperature Monitoring

Relying on a single sensor creates a single point of failure. High-reliability systems often use multiple-survey thermocouples to provide redundant temperature readings. This ensures that if one sensor fails or provides an inaccurate reading, the control system can still rely on the others to maintain safe operation.

Power Failure Protection

A sudden loss of power during a high-temperature cycle is extremely dangerous. An Uninterruptible Power Supply (UPS) is a crucial option that provides backup power, allowing the system's PLC to execute a controlled, safe shutdown sequence rather than a chaotic and potentially damaging stop.

Managing Atmosphere and Pressure Hazards

Controlling the furnace's internal environment is fundamental to both the process and its safety. Errors in managing vacuum or process gas can lead to ruined materials or dangerous reactions.

Automated Vacuum and Gas Control

Modern furnaces use a Programmable Logic Controller (PLC) to automate complex sequences like pump-downs, gas backfills, and venting. By automating these critical steps, the PLC significantly reduces the risk of human error, which is a common cause of accidents.

Gas Leakage Detection

For furnaces that use reactive, flammable, or inert process gases, a gas leakage detection system is an essential safety measure. These sensors monitor the area around the furnace and will trigger an alarm and potentially initiate a shutdown if a leak is detected, preventing the risk of fire, explosion, or asphyxiation.

Pressure and Vacuum Monitoring

A digital vacuum display and associated gauges provide the operator with real-time, critical information about the system's status. Constant and clear feedback on the internal pressure is fundamental for situational awareness, allowing operators to spot anomalies before they become critical problems.

Inherent Safety and Operator Control

Beyond active systems, safety is built into the furnace's design, from its materials to the direct control given to the operator.

Material Integrity and Containment

The furnace chamber and tubes are constructed from high-quality materials like graphite, tungsten, molybdenum, quartz, or ceramics. These materials are chosen for their ability to withstand extreme temperatures and resist corrosion, ensuring the physical integrity of the furnace and containment of the process.

Component Protection

Features like a recirculating chiller are used to cool components such as silicone o-rings and seals. Protecting these seals is vital for safety, as their failure could lead to a sudden loss of vacuum or atmosphere integrity.

Manual Intervention (Emergency Stop)

Despite advanced automation, the operator must have the final say. The emergency stop button is a hardwired function that immediately cuts all power to hazardous components. It is the ultimate manual override for any situation where the operator perceives an immediate danger.

Understanding the Trade-offs

Not all safety features are standard on every furnace. The required level of safety is directly tied to the process risk and budget.

The Baseline for Safety

Core features like an emergency stop and basic over-temperature protection are non-negotiable and included on virtually all systems. These represent the absolute minimum for safe operation.

Process-Specific Risks Dictate Features

Optional features are driven by your specific application. A furnace used for simple annealing in a vacuum does not require the same gas leakage detection system as one used for chemical vapor deposition with flammable precursor gases.

The Cost of Redundancy

Adding features like a UPS, multiple thermocouples, or advanced data logging increases the initial cost and complexity of the system. The trade-off is between the upfront investment and the increased safety margin, which is crucial when processing high-value materials or running high-risk processes.

Making the Right Choice for Your Goal

When specifying a vacuum furnace, match the safety features to the intended application.

- If your primary focus is standard heat treating in a vacuum: Ensure the furnace has robust over-temperature protection, a reliable UPS for safe shutdowns, and a clear emergency stop.

- If your primary focus is processing with reactive gases: Gas leakage detection, a high-integrity vacuum system, and a PLC-automated gas handling manifold are critical safety requirements.

- If your primary focus is high-value or mission-critical parts: Invest in redundancy with multiple thermocouples and comprehensive data logging to protect the load and verify process integrity.

Ultimately, viewing safety as an integrated system, rather than a checklist of features, is the most effective way to ensure a secure operational environment.

Summary Table:

| Safety Feature | Purpose | Key Components |

|---|---|---|

| Over-Temperature Protection | Prevents thermal runaway by cutting power | Dedicated controller, heating elements |

| Redundant Temperature Monitoring | Ensures accurate readings with backup sensors | Multiple thermocouples |

| Power Failure Protection | Enables safe shutdown during outages | Uninterruptible Power Supply (UPS) |

| Gas Leakage Detection | Alerts to leaks of flammable or reactive gases | Sensors, alarm systems |

| Emergency Stop | Allows immediate manual override in emergencies | Hardwired button |

| Material Integrity | Withstands extreme conditions for containment | Graphite, tungsten, ceramics |

Ensure your lab's safety with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by strong deep customization capabilities to precisely meet your unique experimental requirements. Don't compromise on safety—contact us today to discuss how our reliable and customizable furnaces can protect your operators, equipment, and valuable materials while enhancing your process efficiency.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control