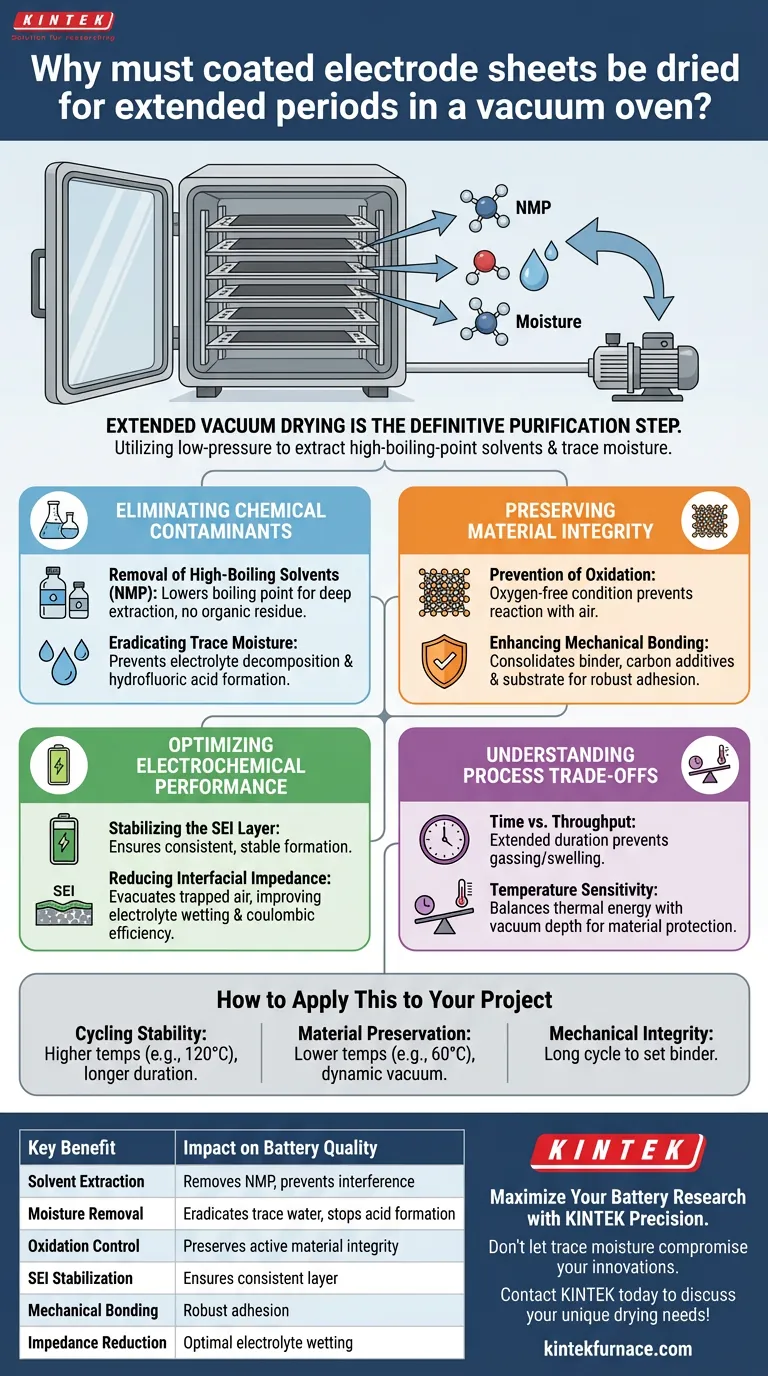

Extended vacuum drying is the definitive purification step necessary to ensure the electrochemical integrity of battery electrodes. This process utilizes a low-pressure environment to rigorously extract high-boiling-point solvents, such as N-methyl-pyrrolidone (NMP), and trace moisture that standard drying methods leave behind.

By lowering ambient pressure, vacuum ovens accelerate evaporation at managed temperatures, ensuring the complete removal of contaminants that would otherwise trigger fatal side reactions. This step is non-negotiable for establishing a stable Solid Electrolyte Interphase (SEI) and achieving high coulombic efficiency.

Eliminating Chemical Contaminants

Removal of High-Boiling Solvents

The slurry used to coat electrodes often contains organic solvents like N-Methyl-2-pyrrolidone (NMP). These solvents have high boiling points, making them difficult to remove through heat alone without damaging the active material.

A vacuum environment significantly reduces the boiling point of these solvents. This allows for deep extraction from the electrode coating, ensuring no organic residue remains to interfere with battery chemistry.

Eradicating Trace Moisture

Water is a critical contaminant in battery systems, particularly those using non-aqueous electrolytes. Even microscopic amounts of moisture can react with the electrolyte to produce hydrofluoric acid or other corrosive byproducts.

Extended drying at elevated temperatures (typically around 120°C) under vacuum ensures trace moisture is desorbed from the porous structure of the electrode. This prevents electrolyte decomposition during subsequent charge and discharge cycles.

Preserving Material Integrity

Prevention of Oxidation

High temperatures are necessary for drying, but they typically accelerate oxidation when oxygen is present. This is a major risk for sensitive active materials and current collectors.

The vacuum oven operates in an oxygen-free condition. This allows the electrode sheets to undergo thermal treatment without reacting with air, preserving the chemical composition and stability of the active materials.

Enhancing Mechanical Bonding

The drying process is not just about removal; it is about setting the structure. Extended thermal treatment helps consolidate the binder (such as PVDF), carbon additives, and the substrate.

This facilitates a robust mechanical bond between the active material and the current collector. Proper adhesion ensures the electrode can withstand the mechanical stress of cycling without delaminating.

Optimizing Electrochemical Performance

Stabilizing the SEI Layer

The presence of impurities interferes with the formation of the Solid Electrolyte Interphase (SEI) layer. A consistent, stable SEI is vital for the battery's longevity and safety.

By removing solvents and moisture, vacuum drying ensures the SEI forms solely based on the intended reaction between the electrolyte and the anode, rather than random reactions with contaminants.

Reducing Interfacial Impedance

Residual solvents and air trapped within the electrode pores act as insulators. They block the electrolyte from fully wetting the active material.

Vacuum drying evacuates air from these micropores. This facilitates optimal contact between the electrolyte and the active material, significantly reducing interfacial impedance and improving the battery's initial coulombic efficiency.

Understanding the Process Trade-offs

Time vs. Throughput

The primary constraint of this process is the "extended" duration required. Thoroughly removing bound moisture and deep-seated solvents is a slow diffusion process.

Rushing this step to increase manufacturing speed often results in gassing or cell swelling later in the battery's life. The time investment in the vacuum oven is a direct trade-off for long-term cycling stability.

Temperature Sensitivity

While higher temperatures accelerate drying, they risk damaging sensitive components. For example, certain catalysts or carbon cloth substrates may require lower temperatures (e.g., 60°C) to prevent degradation.

Operators must balance thermal energy with vacuum depth. Using a deeper vacuum allows for effective drying at these lower temperatures, protecting the material while still achieving the necessary purity.

How to Apply This to Your Project

- If your primary focus is Cycling Stability: Prioritize higher temperatures (e.g., 120°C) for longer durations to ensure absolute moisture elimination and stable SEI formation.

- If your primary focus is Material Preservation: Utilize a dynamic vacuum environment at lower temperatures (e.g., 60°C) to prevent thermal oxidation of sensitive catalysts or binders.

- If your primary focus is Mechanical Integrity: Ensure the vacuum cycle is long enough to fully set the binder, guaranteeing robust adhesion between the coating and the current collector.

The vacuum drying phase is the gatekeeper of quality, determining whether an electrode will perform reliably or degrade prematurely.

Summary Table:

| Key Benefit | Impact on Battery Quality |

|---|---|

| Solvent Extraction | Removes high-boiling NMP to prevent chemical interference |

| Moisture Removal | Eradicates trace water to stop hydrofluoric acid formation |

| Oxidation Control | Oxygen-free environment preserves active material integrity |

| SEI Stabilization | Ensures a consistent Solid Electrolyte Interphase layer |

| Mechanical Bonding | Consolidates binders for robust adhesion to current collectors |

| Impedance Reduction | Evacuates pores to ensure optimal electrolyte wetting |

Maximize Your Battery Research with KINTEK Precision

Don't let trace moisture or residual solvents compromise your energy storage innovations. KINTEK provides advanced, customizable vacuum and high-temperature furnace systems designed to ensure your electrode sheets achieve the highest coulombic efficiency and cycling stability.

Backed by expert R&D and manufacturing, our range of Muffle, Tube, Rotary, Vacuum, and CVD systems is engineered to meet the rigorous demands of modern material science. Whether you are scaling up production or refining sensitive catalysts, our technical experts are ready to help you find the perfect thermal solution.

Contact KINTEK today to discuss your unique drying needs!

Visual Guide

References

- Jasreet Kaur, José A. Alarco. Sustainable Manufacturing of Graphitic Carbon from Bio‐Waste Using Flash Heating for Anode Material of Lithium‐Ion Batteries with Optimal Performance. DOI: 10.1002/adsu.202300610

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How have graphite heating elements evolved for use in vacuum furnaces? Achieve 3000°C Precision & Reliability

- How does a precise temperature control system prevent Rubidium Chloride loss? Optimize Vacuum Distillation Yield

- Why is a high vacuum box sintering furnace required for B4C/Al composites? Unlock Peak Composite Performance

- What is sinter used for in blast furnace? The Engineered Feed for Peak Efficiency

- How does the digital display intelligent temperature control system work in vacuum sintering furnaces? Achieve Precise Thermal Management

- What is the difference between vacuum heat treatment and heat treatment? Achieve Superior Material Performance

- How does a vacuum annealing furnace modify the bond coat? Optimize TBC Systems for Superior Thermal Protection

- What are the functions of the vacuum chamber in the furnace? Ensure Purity and Precision in High-Temp Processes