At its core, vacuum heat treatment is a specialized form of heat treatment. The fundamental difference is the environment: conventional heat treatment occurs in atmospheric air, while vacuum heat treatment is performed in a sealed furnace where the air has been removed. This oxygen-free environment prevents unwanted chemical reactions, like oxidation, that occur when heating metals in the open air.

While both methods use heat to alter a material's properties, conventional heat treatment exposes the material to atmospheric gases. Vacuum heat treatment isolates the material in a contamination-free vacuum, enabling superior control and resulting in a cleaner, stronger, and more uniform product.

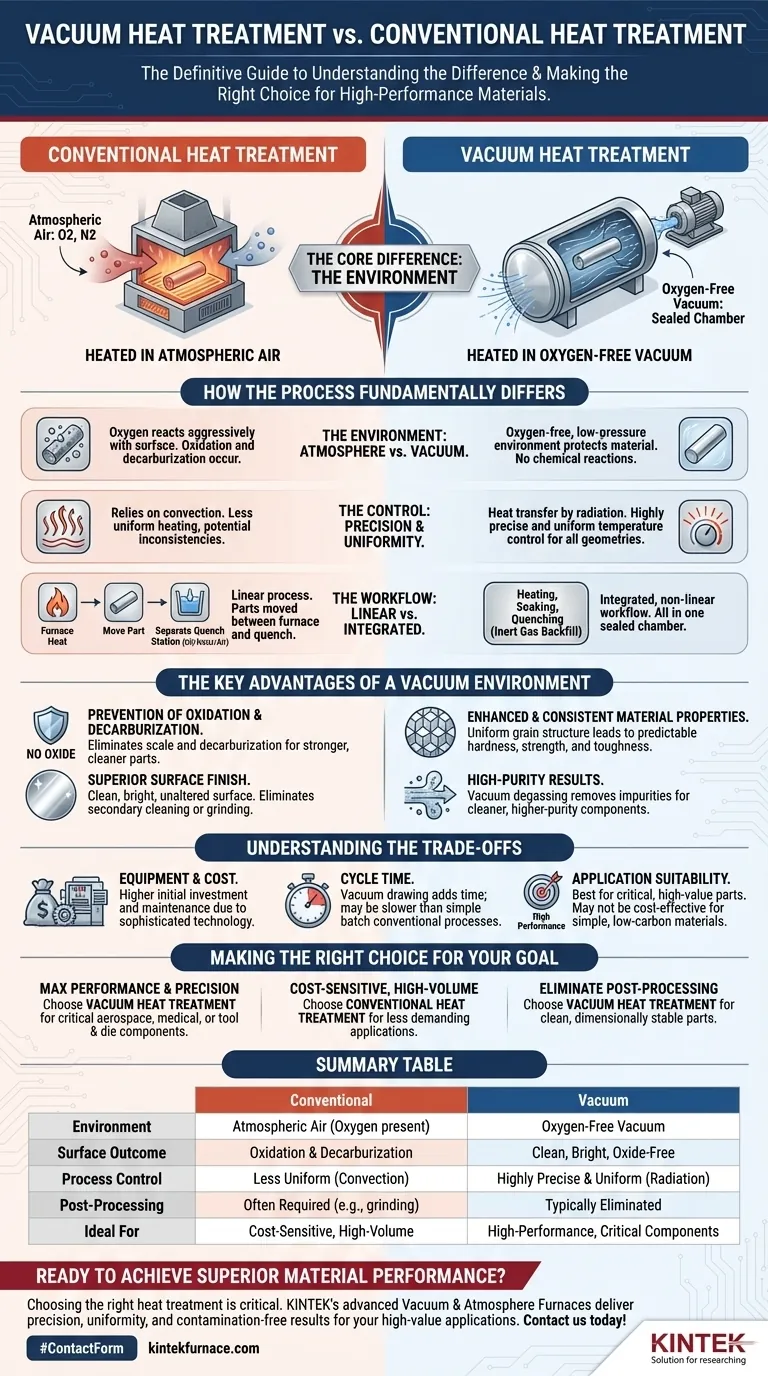

How the Process Fundamentally Differs

The choice between vacuum and conventional methods comes down to the environment in which the material is heated and cooled. This single factor changes the entire workflow and the quality of the final result.

The Environment: Atmosphere vs. Vacuum

Conventional heat treatment heats parts in the presence of the gases that make up our atmosphere, primarily nitrogen and oxygen. At high temperatures, oxygen aggressively reacts with the metal's surface.

Vacuum heat treatment begins by placing parts in a sealed chamber and using powerful pumps to remove the air. This creates a low-pressure, oxygen-free environment that protects the material throughout the entire cycle.

The Control: Precision and Uniformity

In a vacuum, heat transfer occurs primarily through radiation, not convection. This allows for extremely precise and uniform temperature control, ensuring the entire part, regardless of its geometry, heats and cools at the intended rate.

Conventional furnaces, which often rely on convection currents in the air, can lead to less uniform heating, creating potential inconsistencies in the material's final properties.

The Workflow: Linear vs. Integrated

A typical conventional process is linear—parts are heated in one furnace and then physically moved to a separate station for quenching (rapid cooling) in oil, water, or air.

A vacuum furnace uses an integrated, non-linear workflow. The heating, soaking, and quenching all occur within the same sealed chamber. After heating, the chamber can be rapidly backfilled with a controlled inert gas like nitrogen or argon to achieve precise cooling rates.

The Key Advantages of a Vacuum Environment

Performing heat treatment in a vacuum is not just about avoiding rust; it fundamentally improves the material. It's a proactive method for achieving superior quality from the start.

Prevention of Oxidation and Decarburization

This is the principal benefit. With no oxygen present, oxidation (the formation of scale on the surface) is completely eliminated. For steels, it also prevents decarburization, a process where carbon is stripped from the surface, making it weaker.

Superior Surface Finish

Because oxidation is prevented, parts emerge from a vacuum furnace with a clean, bright, and unaltered surface. This often eliminates the need for costly and time-consuming secondary operations like sandblasting, chemical cleaning, or grinding.

Enhanced and Consistent Material Properties

The precise control over heating and cooling cycles results in a more uniform grain structure throughout the material. This directly leads to more predictable and consistent improvements in mechanical properties like hardness, strength, and toughness.

High-Purity Results

The vacuum can actively clean the material. During heating, impurities near the surface with a high vapor pressure can be pulled out of the material, a process known as vacuum degassing. This results in a cleaner, higher-purity component.

Understanding the Trade-offs

While vacuum heat treatment offers significant advantages, it is not the default choice for every application. Understanding its limitations is key to making an informed decision.

Equipment and Cost

Vacuum furnaces are sophisticated machines requiring sealed chambers, complex controls, and powerful pumping systems. This makes their initial investment and maintenance costs significantly higher than many conventional furnace types.

Cycle Time

The process of drawing a vacuum adds time to the beginning of each cycle. For simple, non-critical parts, a conventional "in-and-out" batch furnace might offer a faster total throughput.

Application Suitability

The benefits of a vacuum furnace are most pronounced in high-performance applications. For simple annealing of raw materials or treating low-carbon steel where a layer of oxide is acceptable or easily removed, the expense of a vacuum process may not be justified.

Making the Right Choice for Your Goal

Your choice depends on the performance requirements of the final part versus the cost and complexity of the process.

- If your primary focus is maximum performance and precision: Choose vacuum heat treatment for its superior control, clean finish, and enhanced material properties, especially for critical components in the aerospace, medical, or tool and die industries.

- If your primary focus is cost-sensitive, high-volume production where surface finish is not critical: Conventional heat treatment is often a more economical and practical solution for less demanding applications.

- If your primary focus is eliminating post-processing steps: Select vacuum heat treatment, as parts emerge clean and dimensionally stable, saving significant time and labor on secondary finishing.

Ultimately, vacuum heat treatment is a modern, highly controlled process designed to achieve metallurgical properties that are difficult or impossible to attain conventionally.

Summary Table:

| Feature | Conventional Heat Treatment | Vacuum Heat Treatment |

|---|---|---|

| Environment | Atmospheric Air (Oxygen present) | Oxygen-Free Vacuum |

| Surface Outcome | Oxidation & Decarburization | Clean, Bright, Oxide-Free |

| Process Control | Less Uniform (Convection) | Highly Precise & Uniform (Radiation) |

| Post-Processing | Often Required (e.g., grinding) | Typically Eliminated |

| Ideal For | Cost-Sensitive, High-Volume Parts | High-Performance, Critical Components |

Ready to Achieve Superior Material Performance?

Choosing the right heat treatment process is critical for the quality and performance of your components. KINTEK's advanced high-temperature furnace solutions, including our robust Vacuum & Atmosphere Furnaces, are engineered to deliver the precision, uniformity, and contamination-free environment your high-value applications demand.

Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced solutions. Our product line, including Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental and production requirements.

Contact us today to discuss how our expertise can enhance your process and deliver cleaner, stronger, and more consistent results. Let's find the perfect solution for your goals.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance